Glazed tile manufactured by using ceramic waste and having broken diamond sand flashing starlight on surface, and preparation method thereof

A technology for glazed tiles and ceramic polishing waste residues, which is applied to glazed tiles and preparation fields with glazed, diamond-like glittering stars on the surface and grease like jade, which can solve the problem that the stone source cannot meet the needs, and achieve unique decorative effects, strong Universality, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in further detail below in conjunction with embodiment.

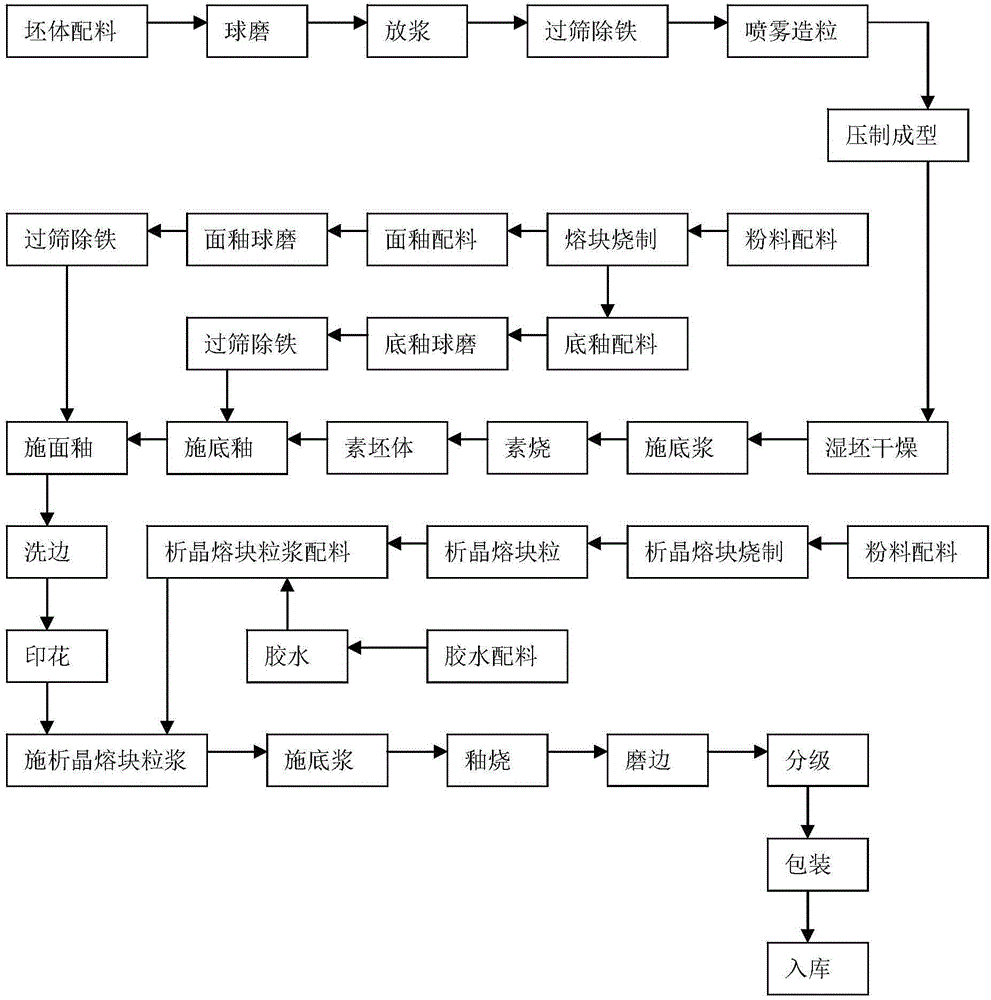

[0048] The surface of the present invention is made of ceramic waste, such as the glazed brick with broken diamond sand shining starlight and its preparation method, which includes the following component preparation and steps:

[0049] A. Preparation of plain body:

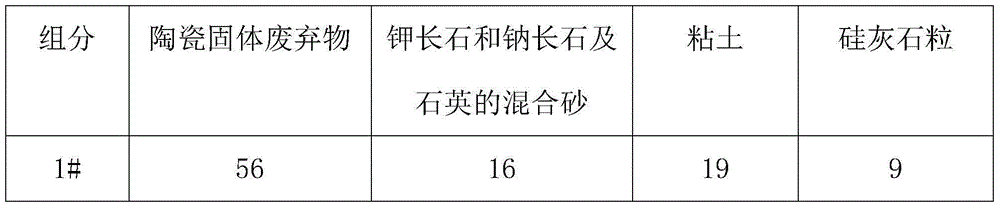

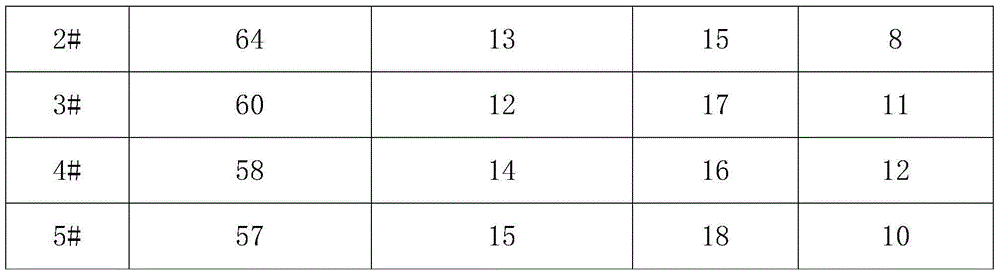

[0050] The composition of the formula of the green body is shown in Table 1:

[0051] Table 1, the formula composition list (parts by weight) of the green body

[0052]

[0053]

[0054] Prepare the green body: weigh ceramic solid waste, potassium feldspar, albite and quartz mixed sand, clay, wollastonite particles according to the composition of the green body in Table 1, add 1-2 parts of water glass, 0.2- 0.4 parts of sodium metasilicate pentahydrate, 50-60 parts of water, finely crushed in a ball mill until the sieve residue of 250 mesh sieve is a slurry with a mass percentage of 4%-5%. Powder with a pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com