Scoria-imitated light heat-preservation composite building block and processing method thereof

A thermal insulation composite, volcano-like technology, applied in other household appliances, applications, building materials and other directions, can solve problems such as poor thermal insulation performance, and achieve good decorative effect, good impermeability, and good thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

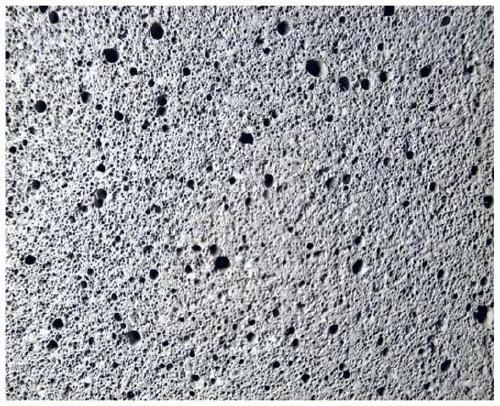

[0032] The embodiment of the present invention provides a kind of volcanic slag-like lightweight thermal insulation composite block, and its specific processing process includes:

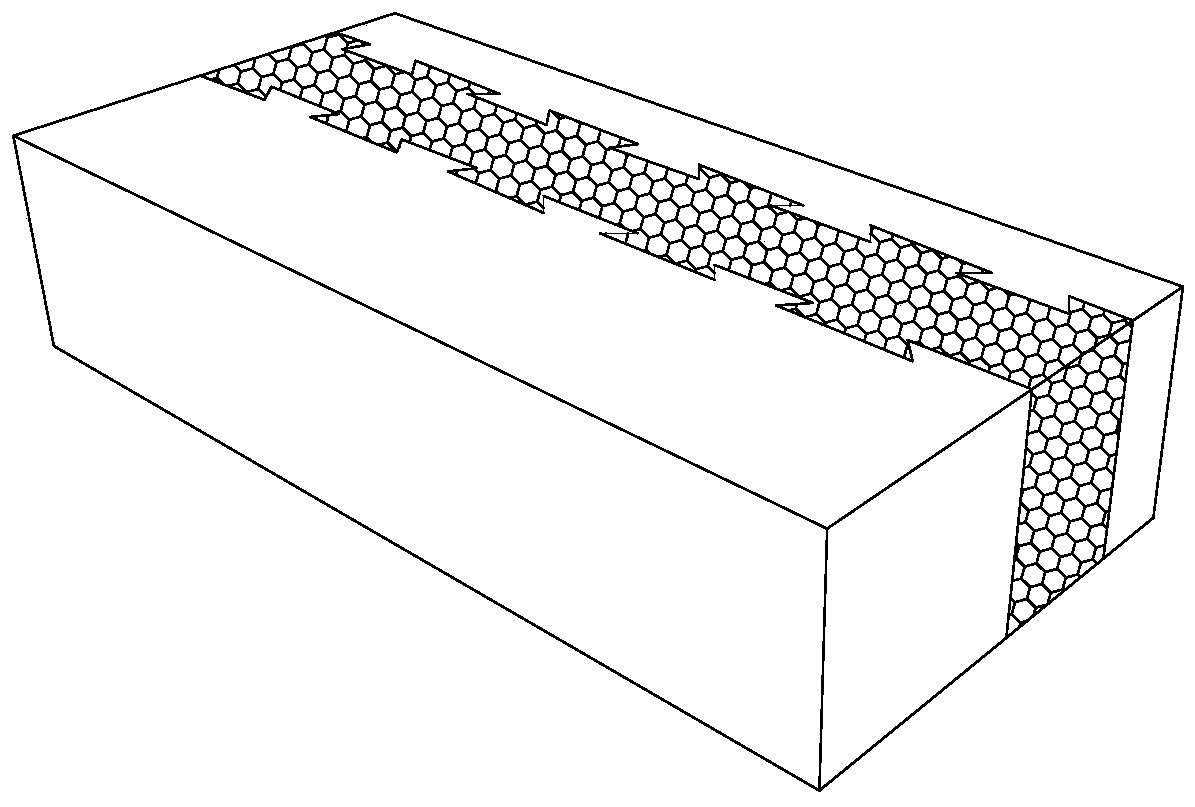

[0033] Fix the 48mm thick EPS insulation core material with dovetail grooves on both sides in the mold, then pour lightweight porous concrete slurry on both sides of the EPS insulation core material, and form lightweight porous concrete after chemical foaming, demoulding and curing in sequence The matrix, and finally surface processed and dried, can be made into a 240mm thick imitation volcanic slag lightweight thermal insulation composite block, and its specific structure is as follows figure 1 shown.

[0034] Specifically, the EPS thermal insulation core material is fixed in the middle of the mould, that is, the thickness of the lightweight porous concrete matrix on both sides of the EPS thermal insulation core material is equal.

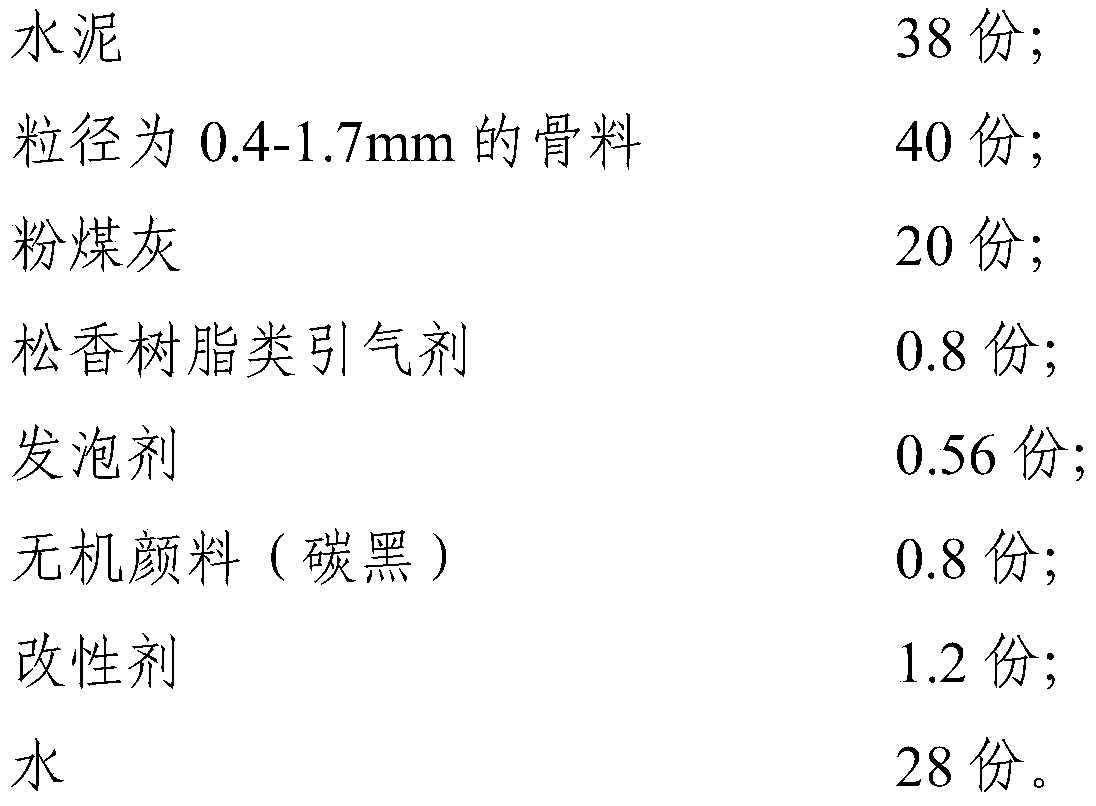

[0035] Specifically, the above-mentioned lightweight porous concr...

Embodiment 2

[0045] The embodiment of the present invention provides a kind of volcanic slag-like lightweight thermal insulation composite block, and its specific processing process includes:

[0046]Fix the 56mm XPS insulation core material with dovetail grooves on both sides in the mold, then pour lightweight porous concrete slurry on both sides of the XPS insulation core material, and then form lightweight porous concrete after chemical foaming, demoulding and curing The substrate, and finally processed and dried on the surface, can be made into a 280mm thick imitation volcanic slag lightweight thermal insulation composite block.

[0047] Specifically, the EPS thermal insulation core material is fixed in the middle of the mould, that is, the thickness of the lightweight porous concrete matrix on both sides of the EPS thermal insulation core material is equal.

[0048] Specifically, the above-mentioned lightweight porous concrete matrix includes the following raw materials in parts by we...

Embodiment 3

[0058] The embodiment of the present invention provides a kind of volcanic slag-like lightweight thermal insulation composite block, and its specific processing process includes:

[0059] Fix the 48mm thick EPS insulation core material with dovetail grooves on both sides in the mold, then pour lightweight porous concrete slurry on both sides of the EPS insulation core material, and form lightweight porous concrete after chemical foaming, demoulding and curing in sequence The substrate, and finally surface processed and dried, can be made into a 240mm thick imitation volcanic slag lightweight thermal insulation composite block.

[0060] Specifically, the EPS insulation core material is fixed at a non-middle position of the mould. Specifically, the thickness of the lightweight porous concrete matrix on one side of the EPS insulation core material is 2.5 times the thickness of the lightweight porous concrete matrix on the other side.

[0061] Specifically, the above-mentioned lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com