Method for quickly preparing polyethylene glycol regulated and controlled nano hydroxyapatite

A technology of nano-hydroxyapatite and polyethylene glycol, which is applied in the field of biomedical materials, can solve the problems of good dispersion and inability to prepare sizes, and achieve good dispersion, mild and controllable preparation conditions, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

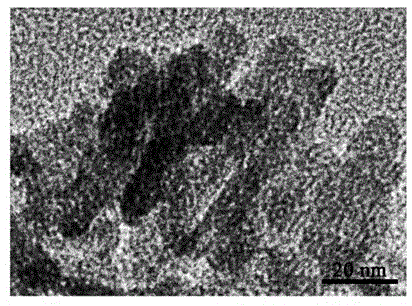

Image

Examples

Embodiment 1

[0029] Prepare 15mM calcium nitrate solution and 9mM diammonium hydrogen phosphate solution respectively. First, cool 50mL of calcium nitrate solution at 0°C, and then add 50mL of diammonium hydrogen phosphate solution into the calcium nitrate solution at 10 drops / min through a constant flow pump. During the dropwise addition, the stirring speed was gradually increased to 500 rpm / min at a rate of 10 rpm / min, and the pH of the reaction system was maintained at 9 with 1M sodium hydroxide solution during the reaction. After the dropwise addition was completed, 0.5 mg of polyethylene glycol-200 was added dropwise. After the dropwise addition was completed, the stirring was stopped and left to stand for 1 hour. The system was rapidly stirred at 500 rpm / min, and the temperature was raised to 70° C., and the stirring was continued for 1 h. Stop heating, and after the reaction system cools down to room temperature, centrifuge and resuspend with deionized water at 4°C at low temperatu...

Embodiment 2

[0032] Prepare 50mM calcium chloride solution and 30mM disodium hydrogen phosphate solution respectively. First, put 50mL of calcium chloride solution at 0°C to cool, and then add 200mL of disodium hydrogen phosphate solution into the calcium chloride solution at 60 drops / min through a constant flow pump. During the dropwise addition, the stirring speed was gradually increased to 1000 rpm / min at a rate of 20 rpm / min, and the pH of the reaction system was maintained at 14 with 1M sodium hydroxide solution during the reaction. After the dropwise addition was completed, 10 mg of polyethylene glycol-2000 was added dropwise. After the dropwise addition was completed, the stirring was stopped and left to stand for 1 hour. The system was rapidly stirred at 1000 rpm / min, and the temperature was raised to 100° C., and the stirring was continued for 1 h. Stop heating, and after the reaction system cools down to room temperature, centrifuge and resuspend with deionized water at a low te...

Embodiment 3

[0034]Prepare 40mM calcium chloride solution and 24mM diammonium hydrogen phosphate solution respectively. First, place 40mL of calcium chloride solution at 0°C to cool, and then add 160mL of diammonium hydrogen phosphate solution into the calcium chloride solution at 40 drops / min through a constant flow pump. During the dropwise addition, the stirring speed was gradually increased to 800 rpm / min at a rate of 15 rpm / min, and the pH of the reaction system was maintained at 10 with 1M sodium hydroxide solution during the reaction. After the dropwise addition is completed, add polyethylene glycol-400 6mg dropwise. After the dropwise addition is completed, stop stirring and let stand for 1h. The system was rapidly stirred at 800 rpm / min, and the temperature was raised to 90° C., and the stirring was continued for 1 h. Stop heating, and after the reaction system cools down to room temperature, centrifuge and resuspend with deionized water at a low temperature of 4°C, and wash the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com