Sulpiride tablet and preparation method thereof

A technology of sulpiride tablets and tablets, which is applied in the direction of pharmaceutical formulas, medical preparations of non-active ingredients, pill delivery, etc., can solve problems such as unsatisfactory dissolution rate of sulpiride tablets, and improve bioavailability and compressibility Good, saving consumption and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) The preparation of solid dispersion carrier, PEG4000 300g, PVPk30 20g are joined in the 95% (ml / ml) ethanol of formula quantity 2 / 3, heat and stir until PEG4000 and PVPk30 dissolve completely, get adjuvant solution; 1000g sulpiride is dissolved in the 95% (ml / ml) ethanol of recipe quantity (remainder) 1 / 3 to obtain main drug solution; Described adjuvant solution and described main drug solution are mixed uniformly to obtain mixed solution; The solution was vacuum-dried for 12 hours (vacuum degree less than 10Pa), the drying temperature was 35°C, and the moisture content was controlled to be less than 1% (mass percentage);

[0018] (2) Tablet preparation, pulverize the material obtained in step (1), and pass through a 100-mesh standard sieve to obtain a solid dispersion powder; put the gained solid dispersion powder, 200 g of lactose, and 300 g of microcrystalline cellulose into a granulator, and dry mix 5min, add 40% (ml / ml) ethanol of 150g as binding agent, set the...

Embodiment 2

[0023] (1) The preparation of solid dispersion carrier, PEG4000 300g, PVPk30 30g are joined in the 95% (ml / ml) ethanol of formula quantity 2 / 3, heat and stir until PEG4000 and PVPk30 dissolve completely, get adjuvant solution; 1000g sulpiride is dissolved in the 95% (ml / ml) ethanol of recipe quantity (remainder) 1 / 3 to obtain main drug solution; Described adjuvant solution and described main drug solution are mixed uniformly to obtain mixed solution; The solution was vacuum-dried for 24 hours (vacuum degree less than 10Pa), the drying temperature was 55°C, and the moisture content was controlled to be less than 1% (mass percentage);

[0024] (2) Tablet preparation, pulverize the material obtained in step (1), and pass through a 120-mesh standard sieve to obtain a solid dispersion powder; put the gained solid dispersion powder, 200 g of lactose, and 300 g of microcrystalline cellulose into a granulator, and dry mix 10min, add the 45% (ml / ml) ethanol of 200g as binding agent, se...

Embodiment 3

[0026] Tablet Quality Check

[0027] 1. Appearance: The surface of the sulpiride tablet prepared in Examples 1 and 2 is smooth, and it is brighter and whiter than the tablet prepared by traditional techniques.

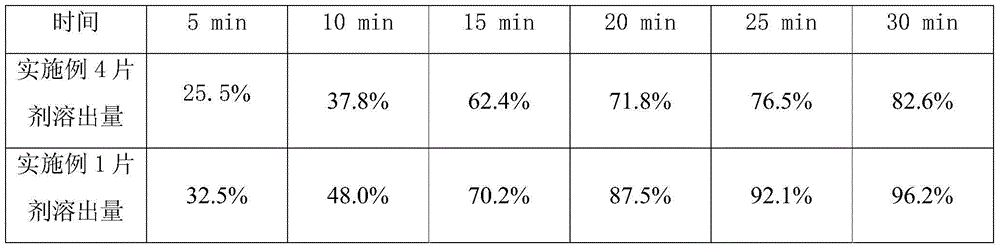

[0028] 2. Dissolution rate:

[0029] Embodiment 1, 2 gained sulpiride tablet respectively gets 6, checks dissolution rate according to Chinese Pharmacopoeia 2010 edition two appendix XC, the dissolution amount of the tablet prepared in embodiment 1, 2 is all more than 85% in 30 minutes (according to labeling meter).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com