Method for preparing molybdenum disulfide thin film

A technology of molybdenum disulfide and thin film, which is applied in the field of preparing molybdenum disulfide thin film, to achieve the effect of controllable thickness, simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

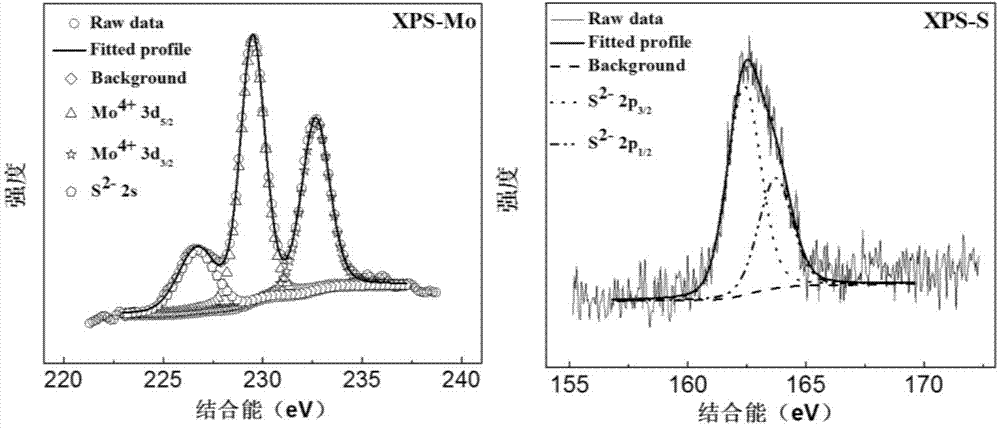

[0028] A method for the preparation of molybdenum disulfide thin films, using molybdenum metal particles and sulfur powder as raw materials to prepare MoS on target substrates by dual-source evaporation in a vacuum environment 2 Thin film, by adjusting the electron beam size of molybdenum metal evaporation, the temperature of sulfur powder evaporation and the growth time, the content ratio of Mo atoms and S atoms is 1:2, Mo atoms and S atoms react on the heated substrate to form MoS 2 Molecules, Molybdenum Disulfide film with controllable layer number was obtained.

Embodiment 2

[0030] A method for preparing a molybdenum disulfide thin film, comprising the following steps:

[0031] 1) Install the cleaned SiO2 at the sample position in the cavity of the electron beam evaporation and resistance evaporation multi-source evaporation coating machine 2 / Si substrate, and then put molybdenum metal particles and sulfur powder in the electron beam evaporation crucible and resistance evaporation crucible respectively;

[0032] 2) Pump the cavity to a background vacuum of 1×10 -3 Below Pa, raise the substrate temperature to 300°C;

[0033] 3) The molybdenum metal evaporation electron beam current is 30mA, the sulfur powder evaporation temperature is 100°C, and the two are pre-evaporated for 2 minutes;

[0034] 4) Open the baffle to start growing, and the growth time is 1 min;

[0035] 5) After the growth is finished, cool down to room temperature naturally to prepare a monomolecular layer molybdenum disulfide thin film.

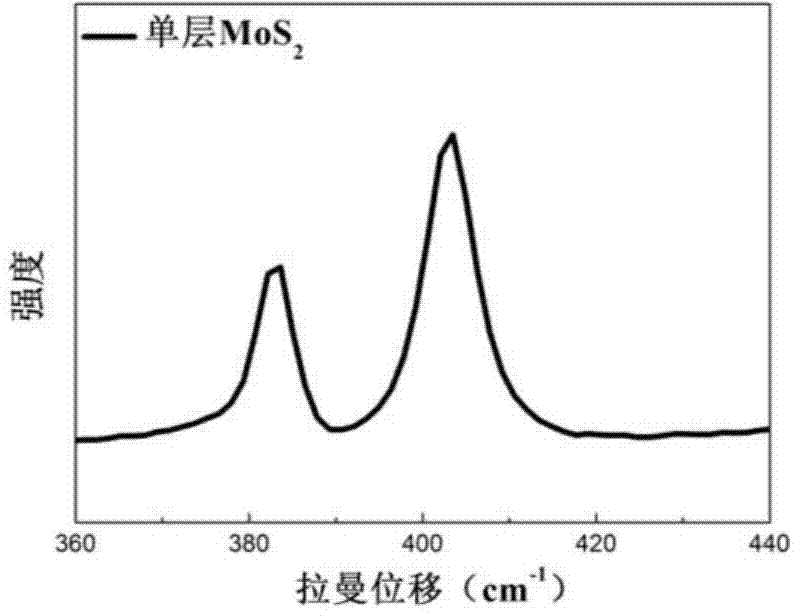

[0036] The Raman spectrum of the mol...

Embodiment 3

[0038] A method for preparing a molybdenum disulfide thin film, comprising the following steps:

[0039] 1) Install the cleaned monocrystalline silicon substrate at the sample position in the cavity of the electron beam evaporation and resistance evaporation multi-source evaporation coating machine, and then put molybdenum metal particles and sulfur powder into the electron beam evaporation crucible and the resistance evaporation crucible respectively;

[0040] 2) Pump the cavity to a background vacuum of 1×10 -3 Below Pa, raise the substrate temperature to 400°C;

[0041] 3) The molybdenum metal evaporation electron beam current is 40mA, the sulfur powder evaporation temperature is 110°C, and the two are pre-evaporated for 2 minutes;

[0042] 4) Open the baffle to start growing, and the growth time is 2 minutes;

[0043] 5) After the growth is completed, cool down to room temperature naturally to prepare a bimolecular layer molybdenum disulfide thin film.

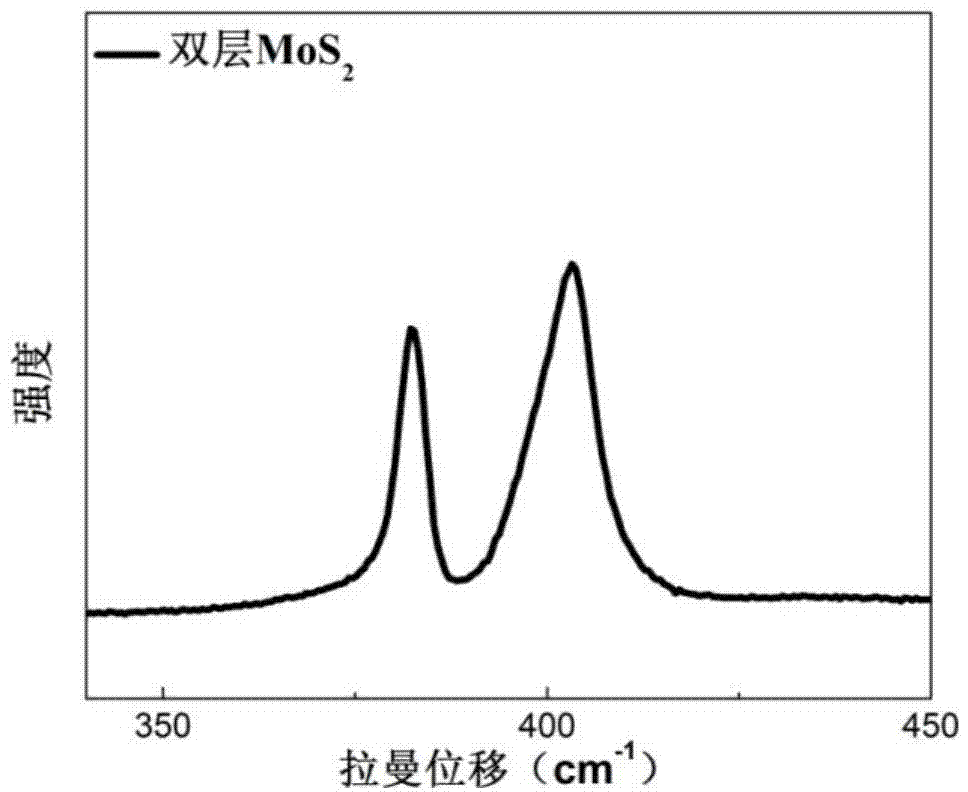

[0044] image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com