Treatment method for titanium extraction from titanium-containing blast furnace slag based on vacuum carbothermal reduction

A treatment method and technology of blast furnace slag, which is applied in the field of metallurgical engineering, can solve the problems of difficulty in extracting titanium from titanium-containing blast furnace slag, high cost, and low titanium recovery rate, so as to reduce the cost of comprehensive utilization of resources, efficiently recycle, and shorten product production. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

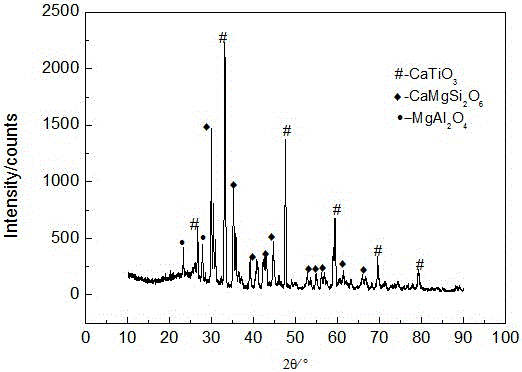

[0030] Titanium-containing blast furnace slag is selected from Panzhihua Iron and Steel Company’s on-site blast furnace slag, and its main phases are as follows figure 1 shown. The titanium-containing blast furnace slag is used as a raw material, and the titanium-containing blast furnace slag extraction treatment method based on vacuum carbothermal reduction of the present invention is used for processing, and the titanium is recovered. The specific method includes the following steps:

[0031] 1) After grinding carbon powder and titanium-containing blast furnace slag, mix them according to the mass ratio of 40:100 to obtain a mixed slag sample;

[0032] 2) Add an appropriate amount of water to the obtained mixed slag sample and press to make pellets to obtain a mixed slag sample pellet;

[0033] 3) At room temperature, put the mixed slag-like pellets into a corundum crucible and place them in a vacuum carbon tube furnace. Vacuum the vacuum carbon tube furnace. When the vacuu...

Embodiment 2

[0038] Titanium-containing blast furnace slag is selected from Panzhihua Iron and Steel Company’s on-site blast furnace slag, and its main phases are as follows figure 1 shown. The titanium-containing blast furnace slag is used as a raw material, and the titanium-containing blast furnace slag extraction treatment method based on vacuum carbothermal reduction of the present invention is used for processing, and the titanium is recovered. The specific method includes the following steps:

[0039] 1) After grinding carbon powder and titanium-containing blast furnace slag, mix them according to the mass ratio of 40:100 to obtain a mixed slag sample;

[0040] 2) Add an appropriate amount of water to the obtained mixed slag sample and press to make pellets to obtain a mixed slag sample pellet;

[0041] 3) At room temperature, put the mixed slag-like pellets into a corundum crucible and place them in a vacuum carbon tube furnace. Vacuum the vacuum carbon tube furnace. When the vacuu...

Embodiment 3

[0046] Titanium-containing blast furnace slag is selected from Panzhihua Iron and Steel Company’s on-site blast furnace slag, and its main phases are as follows figure 1 shown. The titanium-containing blast furnace slag is used as a raw material, and the titanium-containing blast furnace slag extraction treatment method based on vacuum carbothermal reduction of the present invention is used for processing, and the titanium is recovered. The specific method includes the following steps:

[0047]1) After grinding carbon powder and titanium-containing blast furnace slag, mix them according to the mass ratio of 40:100 to obtain a mixed slag sample;

[0048] 2) Add an appropriate amount of water to the obtained mixed slag sample and press to make pellets to obtain a mixed slag sample pellet;

[0049] 3) At room temperature, put the mixed slag-like pellets into a corundum crucible and place them in a vacuum carbon tube furnace. Vacuum the vacuum carbon tube furnace. When the vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com