A method for preparing wood-plastic composite materials by subcritical water extrusion

A wood-plastic composite material and subcritical water technology, which is applied in the research field of reactive extrusion of polymer materials, can solve the problems of environmental pollution, low economic benefits, time-consuming and energy consumption, etc., and achieves low environmental pollution, low labor intensity, contact less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

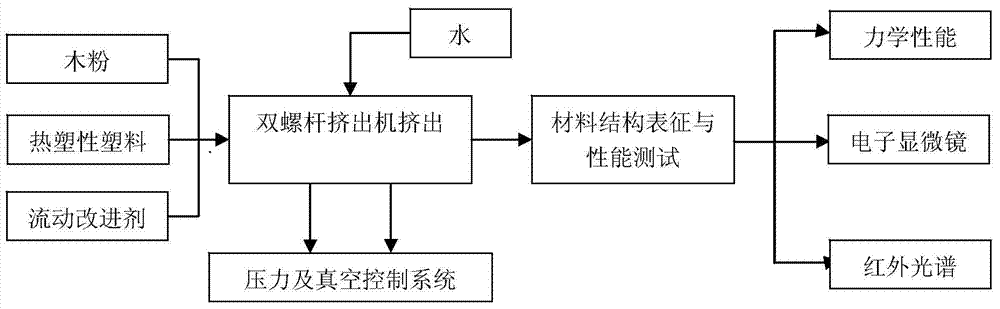

Method used

Image

Examples

Embodiment 1

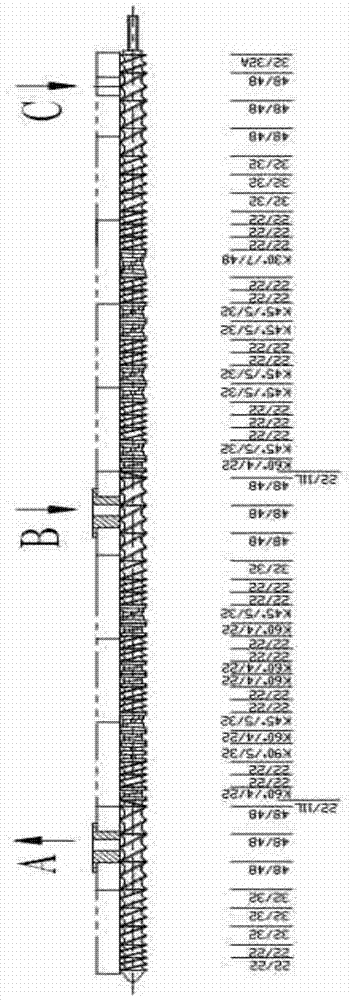

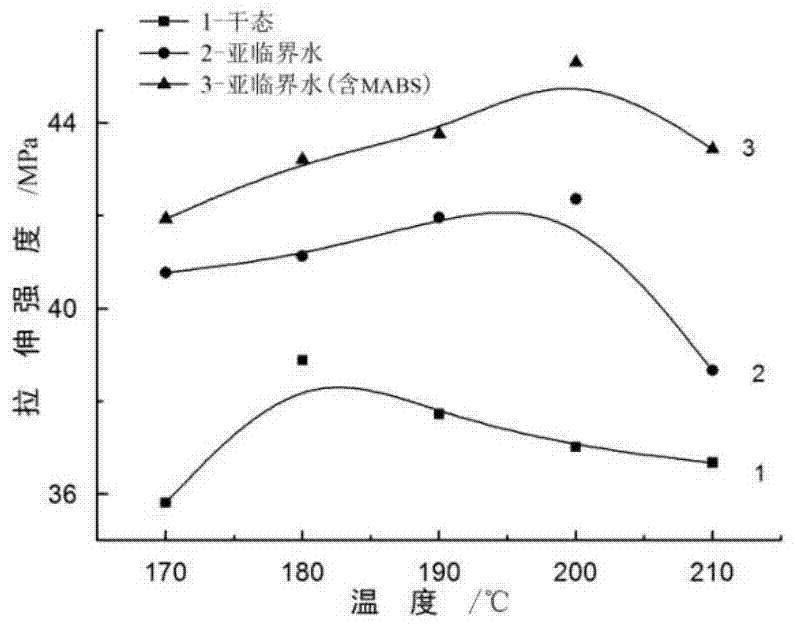

[0044] Example 1 (subcritical water extrusion): 80 mesh eucalyptus wood powder, produced by Shanghai Jiafeng Wood Powder Co., Ltd., 200g of the above wood powder and ABS (Zhenjiang Chimei Chemical Co., Ltd.) 300g are mixed; the mixture is added together In a co-rotating twin-screw extruder (Nanjing Coperion-Keya Machinery Equipment Co., Ltd.) with a diameter of 20mm and an aspect ratio of 32, the screw speed is controlled at 100r / min, and the extrusion temperature is 180°C. The blending reaction is carried out; at the same time, water is metered and injected at the screw structure diagram B, the pressure in the extruder is controlled by the metering pump and the reaction temperature, and it is 1.00 MPa at 180 ° C; The volatile gas generated during the reaction is removed; the extruded product is air-cooled and granulated to obtain an ABS-based wood-plastic composite material.

[0045] Put the above-mentioned extrusion blending and granulation product into an open mixer at 180°...

Embodiment 2

[0046] Example 2 (subcritical water extrusion): 200g of the above-mentioned wood powder, 275g of ABS (Zhenjiang Chimei Chemical Co., Ltd.) and 25g of maleic anhydride grafted ABS (MABS, Nanjing Qiangjian Plastic Co., Ltd.) were mixed, and the mixture And add in the above-mentioned twin-screw extruder, its screw speed, temperature, water injection speed and pressure condition are identical with embodiment 1.

Embodiment 3

[0047] Example 3 (subcritical water extrusion): 150g of the above-mentioned wood flour, ABS (Zhenjiang Chimei Chemical Co., Ltd.) 325g and maleic anhydride grafted ABS (MABS, Nanjing Qiangjian Plastic Co., Ltd.) 25g were mixed, and the mixture And add in the above-mentioned twin-screw extruder, its screw speed, temperature, water injection speed and pressure condition are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com