Nano-modified polyurethane packaging material and preparation method thereof

A packaging material and nano-modification technology, applied in the field of structural materials and their preparation, packaging materials, and composite materials, can solve problems such as unfavorable environmental protection and water and soil conservation, damage to instruments and equipment, and poor anti-extrusion effects. To achieve the effects of water and soil conservation, low production costs, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

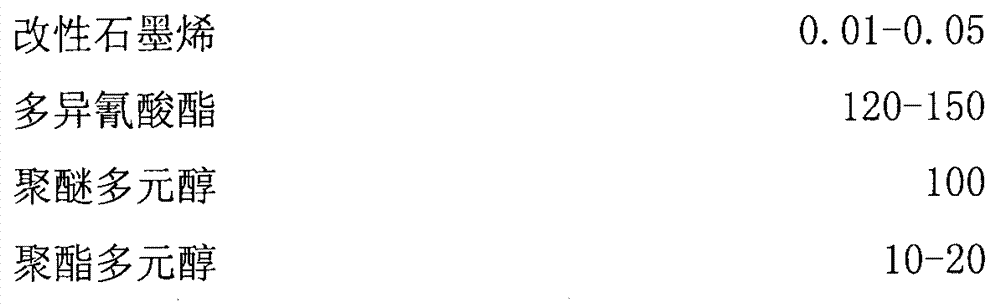

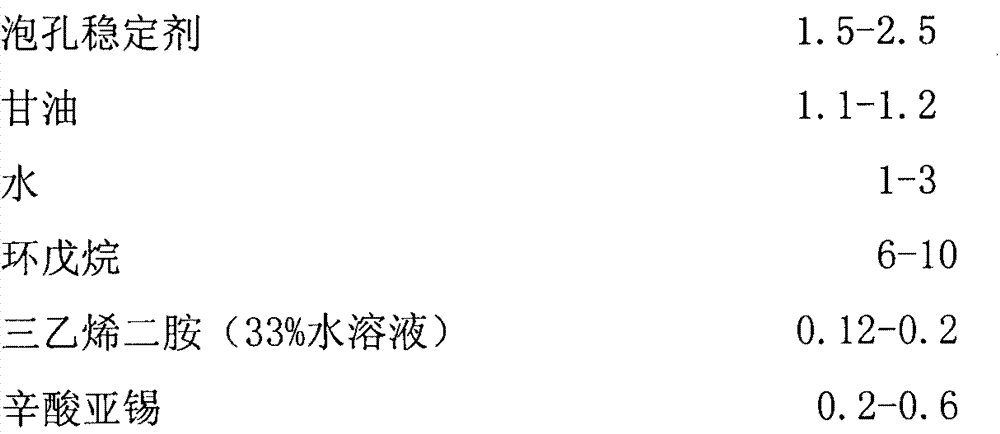

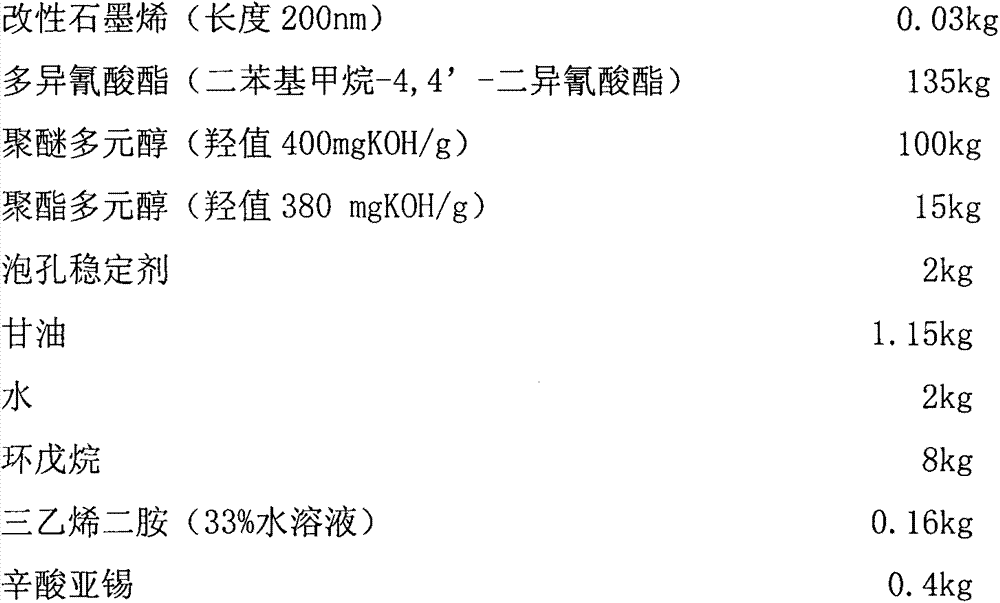

[0021] Embodiment 1: a kind of nano-modified polyurethane packaging material and preparation method thereof, its preparation process is:

[0022]

[0023] (1), according to the weight ratio of graphene and thionyl chloride is 4:100, weigh graphene and thionyl chloride, add to the reaction vessel and mix, stir and react at 70°C for 30h, after the reaction, remove the excess by distillation under reduced pressure thionyl chloride to obtain acid-chlorinated graphene, then add 20 parts by weight of ethylene glycol, react at 100°C for 60h, centrifuge, wash twice with tetrahydrofuran and dichloromethane, and dry in vacuum to obtain a modified Graphene

[0024] (2), take each raw material by formula quantity;

[0025] (3), the modified graphene, polyether polyol, polyester polyol, cell stabilizer, glycerin, water, cyclopentane, triethylenediamine (33% aqueous solution) and stannous octoate are placed in mechanical stirring Stir in the kettle for 15 minutes to prepare white mater...

Embodiment 2

[0027] Embodiment 2: a kind of nano-modified polyurethane packaging material and preparation method thereof, its preparation process is:

[0028]

[0029]

[0030] (1), according to the graphene and thionyl chloride weight ratio is 2: 100, weigh graphene and thionyl chloride, add in the reaction container and mix, stir and react at 70 ℃ for 20h, after the reaction is over, remove the excess by vacuum distillation thionyl chloride to obtain acid-chlorinated graphene, then add 15 parts by weight of ethylene glycol, react at 100°C for 48h, centrifuge, wash twice with tetrahydrofuran and dichloromethane successively, and dry in vacuum to obtain a modified Graphene

[0031] (2), take each raw material by formula quantity;

[0032] (3), the modified graphene, polyether polyol, polyester polyol, cell stabilizer, glycerin, water, cyclopentane, triethylenediamine (33% aqueous solution) and stannous octoate are placed in mechanical stirring Stir in the kettle for 10 minutes to p...

Embodiment 3

[0034] Embodiment 3: a kind of nano-modified polyurethane packaging material and preparation method thereof, its preparation process is:

[0035]

[0036] (1), according to the graphene and thionyl chloride weight ratio is 6: 100, weigh graphene and thionyl chloride, add to the reaction vessel and mix, stir and react at 70°C for 40h, after the reaction is over, remove the excess by distillation under reduced pressure thionyl chloride to obtain acid-chlorinated graphene, then add 25 parts by weight of ethylene glycol, react at 100°C for 72h, centrifuge, wash twice with tetrahydrofuran and dichloromethane successively, and dry in vacuum to obtain a modified Graphene

[0037] (2), take each raw material by formula quantity;

[0038] (3), the modified graphene, polyether polyol, polyester polyol, cell stabilizer, glycerin, water, cyclopentane, triethylenediamine (33% aqueous solution) and stannous octoate are placed in mechanical stirring Stir in the kettle for 20 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com