Anti-crack water-proofing agent and preparation method thereof

An anti-cracking waterproofing agent, the technology of weight percentage, applied in the field of concrete additives, can solve the problems of decreased bonding strength, inapplicability in places with special requirements for strength and anti-seepage, and insignificant compensation for plastic shrinkage, so as to improve waterproofing and anti-seepage. The effect of improving permeability and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

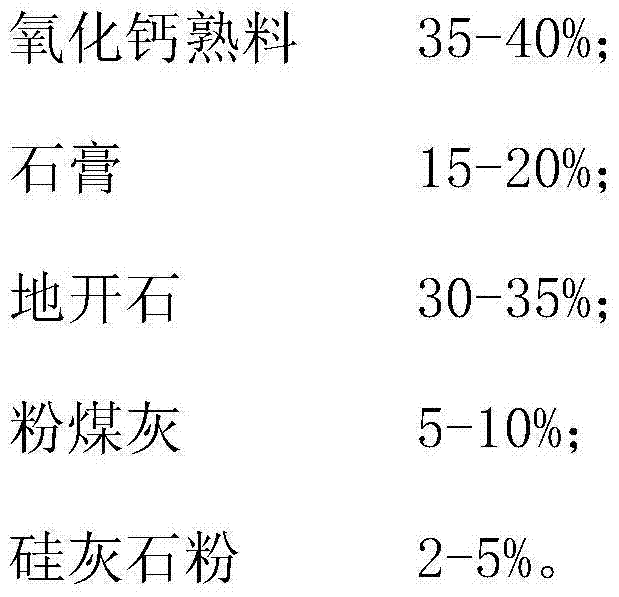

Method used

Image

Examples

Embodiment 1

[0017] In the present embodiment, the anti-cracking and waterproofing agent adopts a mass percentage of 37% of calcium oxide clinker, 18% of gypsum, 34% of dickite, 7% of fly ash, and 4% of wollastonite powder. Calcium oxide clinker, gypsum , the dickite is ground to a certain fineness in a mill, and then mixed with fly ash and wollastonite powder. Or add 37% of calcium oxide clinker, 18% of gypsum, 34% of dickite, 7% of fly ash, and 4% of wollastonite powder into the mill for uniform grinding, and transport it to the homogenization store for homogenization . Then obtain this anti-cracking waterproof agent. The calcium oxide clinker in this embodiment is a single substance obtained by calcining limestone powder above 1500°C, and its weight ratio and its components are as follows: SiO 2 6.95%, Al 2 o 3 5.50%; Fe 2 o 3 2.21%, CaO 82.04%, MgO 0.82%, loss on ignition 1.26%, and the rest are unavoidable impurities, and the weight percentage of free calcium oxide in the calciu...

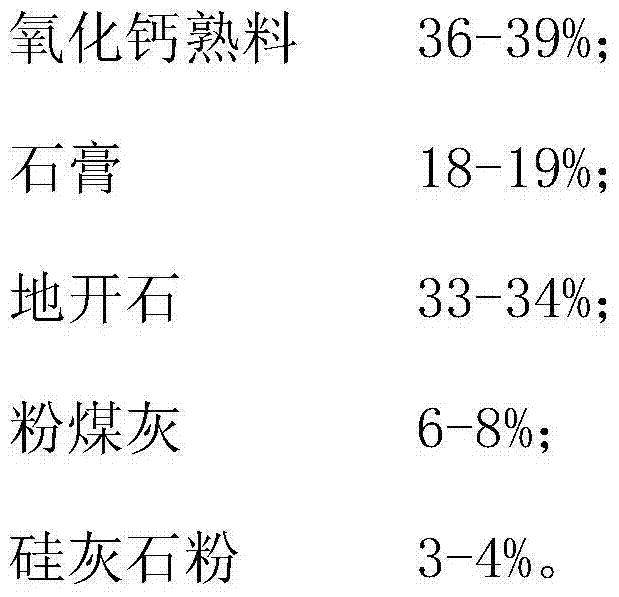

Embodiment 2

[0020] In the present embodiment, the anti-cracking waterproofing agent adopts a mass ratio of calcium oxide clinker 39%, gypsum 19%, dickite 33%, fly ash 6%, wollastonite powder 3%, calcium oxide clinker, gypsum, ground The stone is ground to a certain fineness in the mill, and then mixed with fly ash and wollastonite powder. Or add 39% of calcium oxide clinker, 19% of gypsum, 33% of dickite, 6% of fly ash, and 3% of wollastonite powder into the mill for uniform grinding, and transport it to the homogenization warehouse for homogenization . Then obtain this anti-cracking waterproof agent. Other can refer to embodiment 1. The calcium oxide clinker in this embodiment is a single substance obtained by calcining limestone powder above 1500°C, and its weight ratio and its components are as follows: SiO 2 7.05%, Al 2 o 3 5.30%; Fe 2 o 3 2.00%, CaO 81.6%, MgO 0.6%, loss on ignition 0.7%, and the balance is unavoidable impurities, and the weight percentage of free calcium oxid...

Embodiment 3

[0022] In the present embodiment, the anti-cracking waterproofing agent adopts a mass ratio of calcium oxide clinker 36%, gypsum 20%, dickite 34%, fly ash 8%, wollastonite powder 2%, calcium oxide clinker, gypsum, ground The stone is ground to a certain fineness in the mill, and then mixed with fly ash and wollastonite powder. Or add 36% of calcium oxide clinker, 20% of gypsum, 34% of dickite, 8% of fly ash, and 2% of wollastonite powder into the mill for uniform grinding, and transport it to the homogenization warehouse for homogenization . Then obtain this anti-cracking waterproof agent. Other can refer to embodiment 1. The calcium oxide clinker in this embodiment is a single substance obtained by calcining limestone powder above 1500°C, and its weight ratio and its components are as follows: SiO 2 7.0%, Al 2 o 3 5.7%; Fe 2 o 3 2.4%, CaO 82%, MgO 1.1%, loss on ignition 0.8%, and the rest are unavoidable impurities, and the weight percentage of free calcium oxide in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com