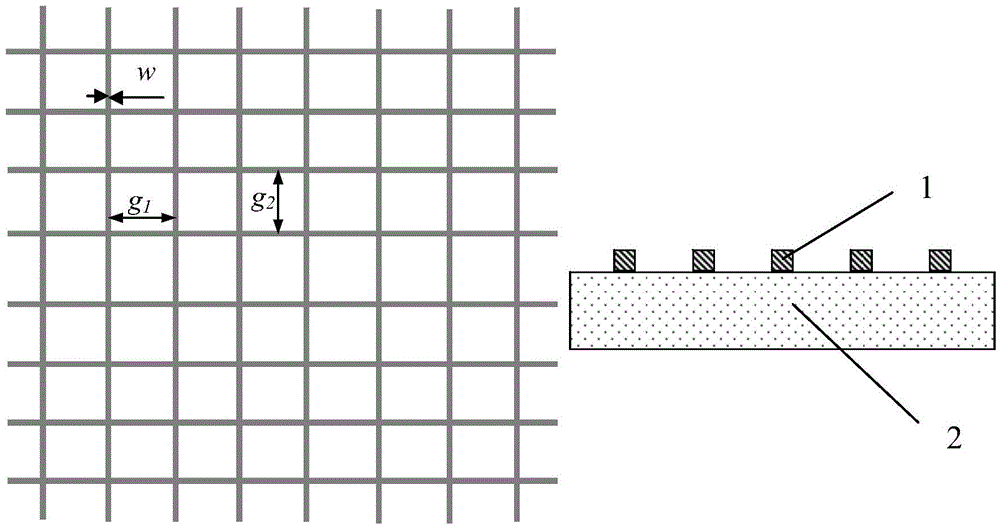

Transparent electrode based on metal nanometer grid and preparing method of transparent electrode

A metal nano and transparent electrode technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of unsatisfactory large-scale production, high price, and poor uniformity, and achieve easy integration and large-scale production. Integrated and mass-produced, structurally shape-tunable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A transparent electrode based on a metal nanogrid is prepared by the following method:

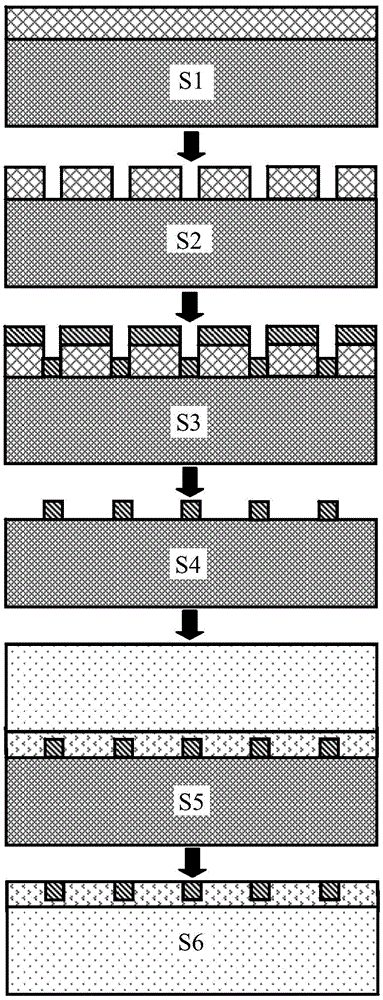

[0068] according to figure 2 Shown process flow diagram, described method comprises the following steps:

[0069] Step 1: Spin-coat photoresist on silicon substrate and bake;

[0070] In this step, bake the cleaned silicon substrate on a hot plate at 180°C for 5-10 minutes, remove the moisture on the surface, spin-coat PMMA (German Allresist company) electron beam positive photoresist, and place it on the hot plate Bake at 180°C for 2 minutes;

[0071] Step 2: Exposure and development, etching the photoresist to form nano-grid patterns on the silicon substrate;

[0072] In this step, the PMMA on the silicon substrate is exposed by electron beam direct writing technology, and a nano-grid pattern is formed on the photoresist layer after development; MIBK (methyl isobutyl ketone) with a mass ratio of 1:3 is used The mixed solution of IPA (isopropyl alcohol) is used as developing s...

Embodiment 2

[0083] A transparent electrode based on a metal nanogrid is prepared by the following method:

[0084] according to figure 2 Shown process flow diagram, described method comprises the following steps:

[0085] Step 1: Spin-coat photoresist on thinned silicon substrate and bake;

[0086] In this step, after the silicon substrate is thinned to 200 μm, it is cleaned, and then placed on a hot plate and baked at 180°C for 5-10 minutes to remove the moisture on the surface, and spin-coat PR1-500A (Futurrex product of the United States) electron beam positive photoresist, and placed on a hot plate to bake at 110°C for 5min;

[0087] Step 2: Exposure and development, etching the photoresist to form nano-grid patterns on the silicon substrate;

[0088] In this step, the PR1-500A on the silicon substrate is exposed by optical lithography using projection lithography equipment, and a nano-grid pattern is formed on the photoresist layer after development; use DR6 (Futurrex Company of ...

Embodiment 3

[0099] A transparent electrode based on a metal nanogrid is prepared by the following method:

[0100] according to figure 2 Shown process flow diagram, described method comprises the following steps:

[0101] Step 1: Spin-coat photoresist on thinned silicon substrate and bake;

[0102] In this step, after the silicon substrate is thinned to 150 μm, it is cleaned, and then placed on a hot plate and baked at 180 ° C for 5 to 10 minutes to remove the moisture on the surface, and spin-coat PMMA (Germany Allresist Company) electron beam positive Glue, and bake on a hot plate at 180°C for 5 minutes;

[0103] Step 2: Exposure and development, etching the photoresist to form nano-grid patterns on the silicon substrate;

[0104] In this step, the PMMA on the silicon substrate is exposed by electron beam direct writing technology, and a nano-grid pattern is formed on the photoresist layer after development; MIBK (methyl isobutyl ketone) with a mass ratio of 1:3 is used The mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com