Method for recycling noble metal from automobile exhaust catalyst

A technology for precious metal recovery and automobile exhaust gas, which is applied in the field of automobile exhaust catalyst precious metal recovery, can solve the problems such as the inability to recycle the tail liquid and the low recovery rate of precious metals, so as to solve the problems of precious metal recovery and environmental protection, the effect of emission reduction is obvious, and the usage amount is reduced Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

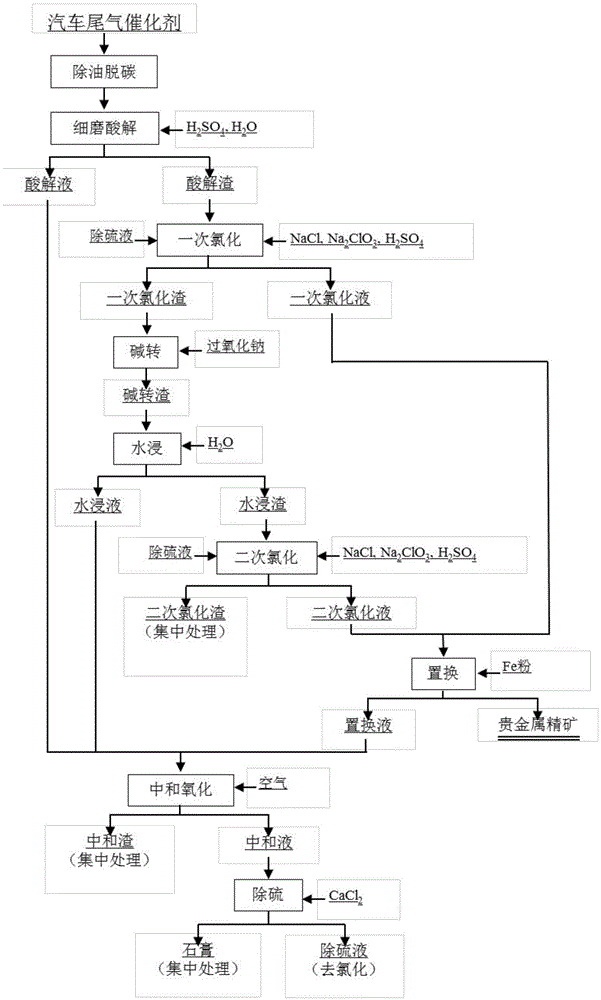

Image

Examples

Embodiment 1

[0025] Put the automobile exhaust catalyst into the oil removal and decarbonization device for oil removal and decarbonization. The oil decarbonization device equipped with the automobile exhaust catalyst is first heated to 110°C, vacuumed to 250Pa, and kept for 30 minutes to perform oil removal treatment. Then raise the temperature of the oil removal and decarbonization device to 350°C, fill it with pure oxygen, keep it warm for 10 minutes, and carry out decarbonization treatment; the material after oil removal and decarbonization is finely ground to -80 mesh, and the finely ground powder is 98% The concentration of industrial concentrated sulfuric acid is 150Kg / m 3 Acid leaching is carried out in the solution, the liquid-solid ratio is 3:1, the acid leaching temperature is 50°C, the acid leaching time is 0.5 hours, and acid leaching is filtered to obtain acid leaching liquid and acid leaching residue; acid leaching residue is mixed with sodium chloride, chloric acid Carry ou...

Embodiment 2

[0027] Put the automobile exhaust catalyst into the oil removal and decarbonization device for oil removal and decarbonization. The oil decarbonization device equipped with the automobile exhaust catalyst is first heated up to 200°C, vacuumed to a pressure of 150Pa, and kept for 60 minutes to perform oil removal treatment. Then heat up the oil removal and decarbonization device to 450°C, fill it with pure oxygen, keep it warm for 30 minutes, and carry out decarburization treatment; the material after oil removal and decarbonization is finely ground to -80 mesh, and the finely ground powder is at 98% The concentration of industrial concentrated sulfuric acid is 250Kg / m 3 Acid leaching is carried out in the solution, the liquid-solid ratio is 5:1, the acid leaching temperature is 90°C, and the acid leaching time is 2 hours. The acid leaching solution and acid leaching residue are obtained by acid leaching filtration; Carry out primary chlorination in the solution of sodium and s...

Embodiment 3

[0029] Put the automobile exhaust catalyst into the oil removal and decarbonization device for oil removal and decarbonization. The oil decarburization device equipped with the automobile exhaust catalyst is first heated to 150°C, vacuumed to a pressure of 200Pa, and kept for 40 minutes to perform oil removal treatment. Then heat up the oil removal and decarbonization device to 400°C, fill it with pure oxygen, keep it warm for 20 minutes, and perform decarburization treatment; The concentration of industrial concentrated sulfuric acid is 200Kg / m 3 Acid leaching is carried out in the solution, the liquid-solid ratio is 4:1, the acid leaching temperature is 60 ° C, the acid leaching time is 1 hour, and the acid leaching is filtered to obtain the acid leaching solution and acid leaching residue; Carry out primary chlorination in the solution of sodium and sulfuric acid to obtain primary chlorination slag and primary chlorination solution, wherein the concentration of sodium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com