A ammonia leaching process for molybdenum calcination to reduce slag formation rate and molybdenum content in slag

A molybdenum calcine and process technology, applied in the field of molybdenum calcine ammonia leaching process, can solve the problems of cumbersome process for recovering molybdenum, hindering the dissolution of molybdenum trioxide, troublesome ammonia leaching slag treatment, etc., and achieves strong repeatability and molybdenum content. The effect of reducing and reducing the rate of slag formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

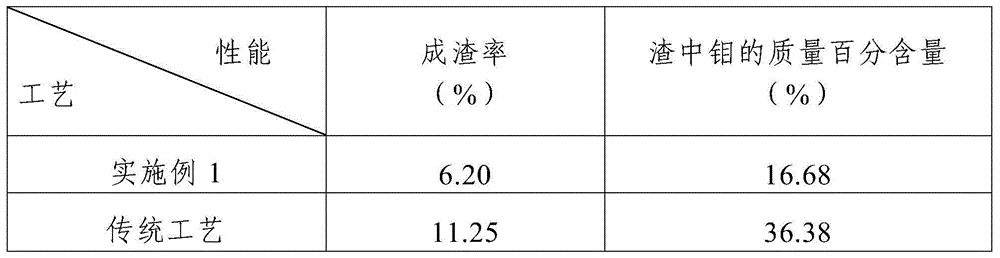

Embodiment 1

[0024] The present embodiment reduces the slagging rate and the molybdenum calcination ammonia leaching process of molybdenum content in slag comprises the following steps:

[0025] Step 1. Mole ratio Mo:NH 3 =1:2.5, solid-to-liquid ratio 1:2.5 Mix molybdenum calcined sand, ammonia water and deionized water evenly to obtain a suspension, and then stir the suspension at a temperature of 65°C until the pH of the suspension is Be 6.8; The mass percentage concentration of described ammoniacal liquor is 26%, and the mass percentage composition of molybdenum in the described molybdenum calcined sand is 63%;

[0026] Step 2, filtering the suspension with a pH value of 6.8 in step 1 to obtain filter cake and filtrate;

[0027] Step 3: The filter cake described in step 2 is washed with ammonia water with a mass percentage concentration of 26%. The number of washings is 3 times, and the washed filter cake is placed in a drying oven to dry at a drying temperature of 100°C. After 8 hour...

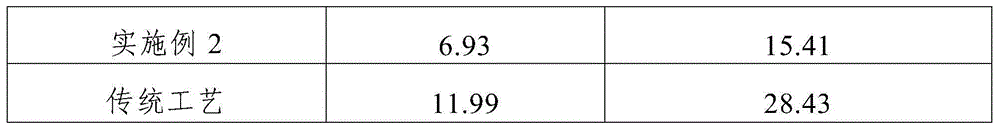

Embodiment 2

[0033] The present embodiment reduces the slagging rate and the molybdenum calcination ammonia leaching process of molybdenum content in slag comprises the following steps:

[0034] Step 1. Mole ratio Mo:NH 3 =1:2, solid-to-liquid ratio 1:2 Mix molybdenum calcined sand, ammonia water and deionized water evenly to obtain a suspension, and then stir the suspension at a temperature of 70°C until the pH of the suspension is Be 7.0; The mass percentage concentration of described ammonia liquor is 28%, and the mass percentage composition of molybdenum in the described molybdenum calcined sand is 61.5%;

[0035] Step 2, filtering the suspension with a pH value of 7.0 in step 1 to obtain filter cake and filtrate;

[0036] Step 3: Wash the filter cake described in Step 2 with ammonia water with a concentration of 28% by mass, the number of washings is 1 time, and place the washed filter cake in a drying oven to dry at a drying temperature of 80°C. After natural cooling for 10 hours, ...

Embodiment 3

[0043] The present embodiment reduces the slagging rate and the molybdenum calcination ammonia leaching process of molybdenum content in slag comprises the following steps:

[0044] Step 1. Mole ratio Mo:NH 3 =1:3, solid-to-liquid ratio 1:3 Mix molybdenum calcined sand, ammonia water and deionized water evenly to obtain a suspension, and then stir the suspension at a temperature of 70°C until the pH of the suspension is Be 6.5; The mass percentage concentration of described ammonia liquor is 25%, and the mass percentage composition of molybdenum in the described molybdenum calcined sand is 62.4%;

[0045] Step 2, filtering the suspension with a pH value of 6.5 in step 1 to obtain filter cake and filtrate;

[0046] Step 3: Wash the filter cake described in step 2 with ammonia water with a mass percentage concentration of 27%, the number of washings is 2 times, and place the washed filter cake in a drying oven to dry at a drying temperature of 80°C. After 8 hours of natural co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com