On-chip integrated beam combining laser based on photonic crystal y-waveguide and manufacturing method thereof

A photonic crystal and two-dimensional photonic crystal technology, which is applied to the structure of optical waveguide light guide and optical waveguide semiconductor, can solve the problem that the semiconductor laser unit device cannot balance high output power and high beam quality well, and avoid the interface Loss, cost and difficulty reduction, compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049] A method for manufacturing an on-chip integrated beam combining laser based on a photonic crystal Y-waveguide, comprising the steps of:

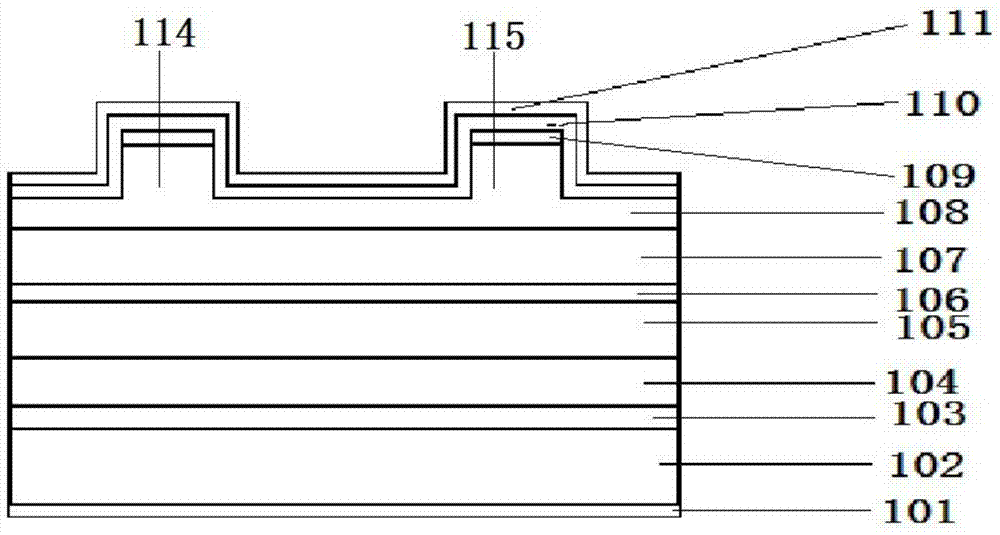

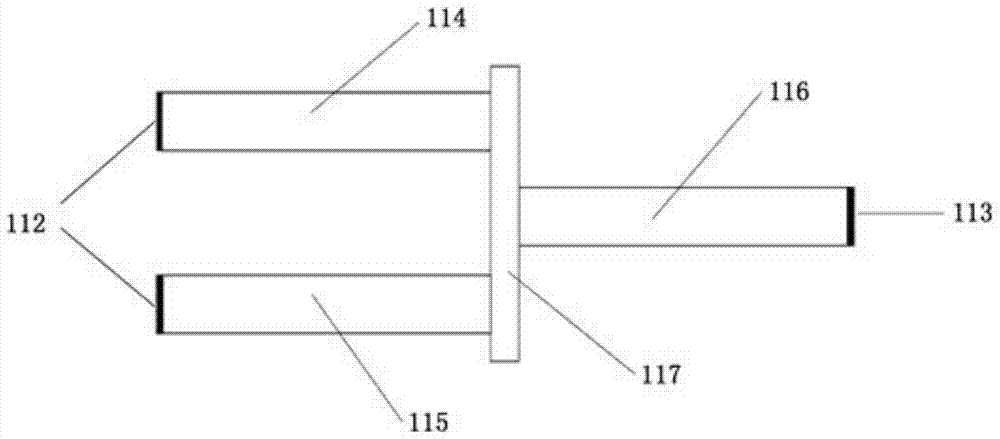

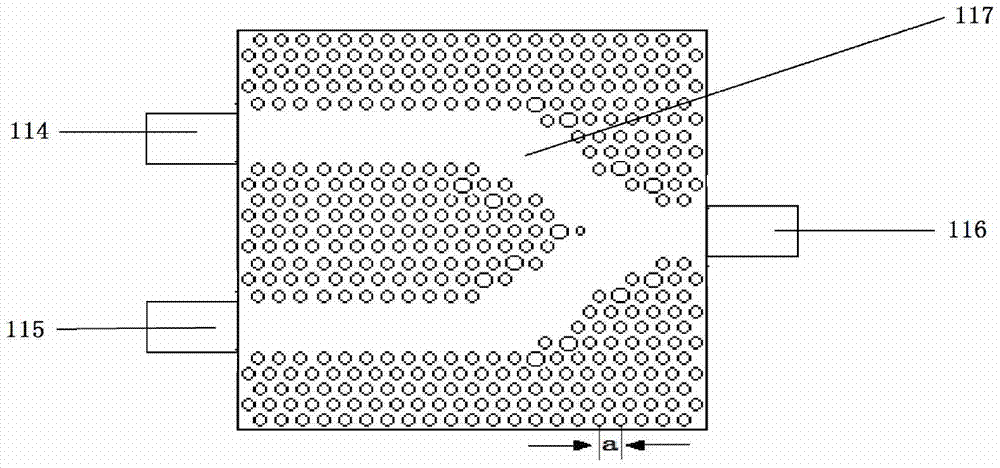

[0050] Step 1, select a GaAs substrate 102; grow a 300nm n-type GaAs buffer layer 103 and a 1500nm Al0.6Ga0.4As n-type cladding layer 104 sequentially on the n-type GaAs substrate 102 by metal-organic chemical vapor deposition , 150nm Al0.3Ga0.7As lower waveguide layer 105, 10nm InGaAlAs single quantum well 106, 150nm Al0.3Ga0.7As upper waveguide layer 107, 1500nm Al0.6Ga0.4As p-type cladding layer 108 and 200nm p-type heavy Doping the capping layer 109, the excitation wavelength of the obtained epitaxial wafer is 808nm;

[0051]Step 2, cleaning the epitaxial wafer with acetone, ethanol, isopropanol;

[0052] Step 3, coating photoresist on the washed epitaxial wafer, then exposing and developing;

[0053] Step 4, using the method of inductively coupled ion etching, etch the p-type cladding layer 109 down to the p-type cladding layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com