Backlight module and optical plate thereof

A technology of backlight module and optical plate, applied in optics, optical components, nonlinear optics, etc., can solve the problems of increasing the number of light interfaces, reducing light utilization, light loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

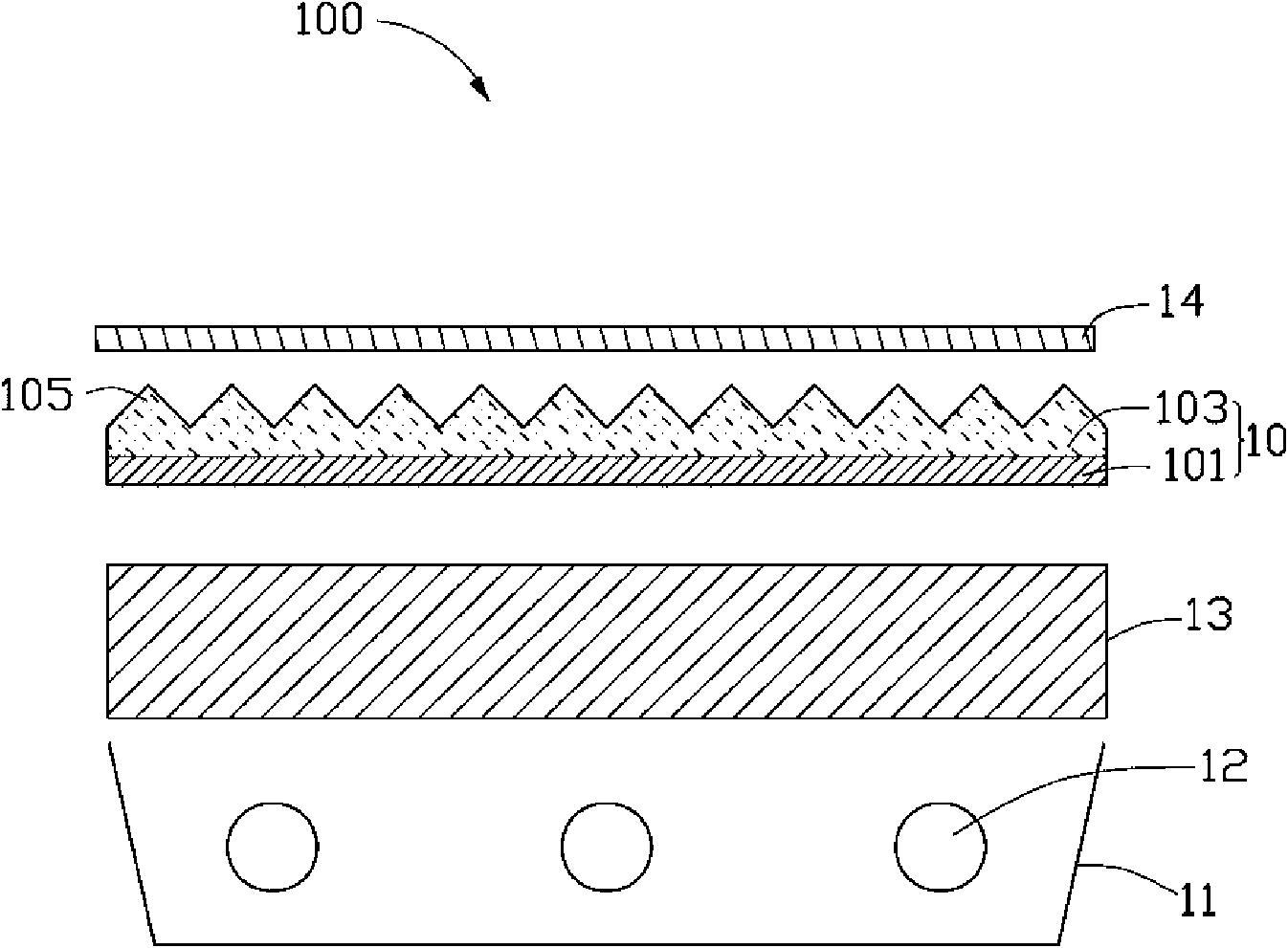

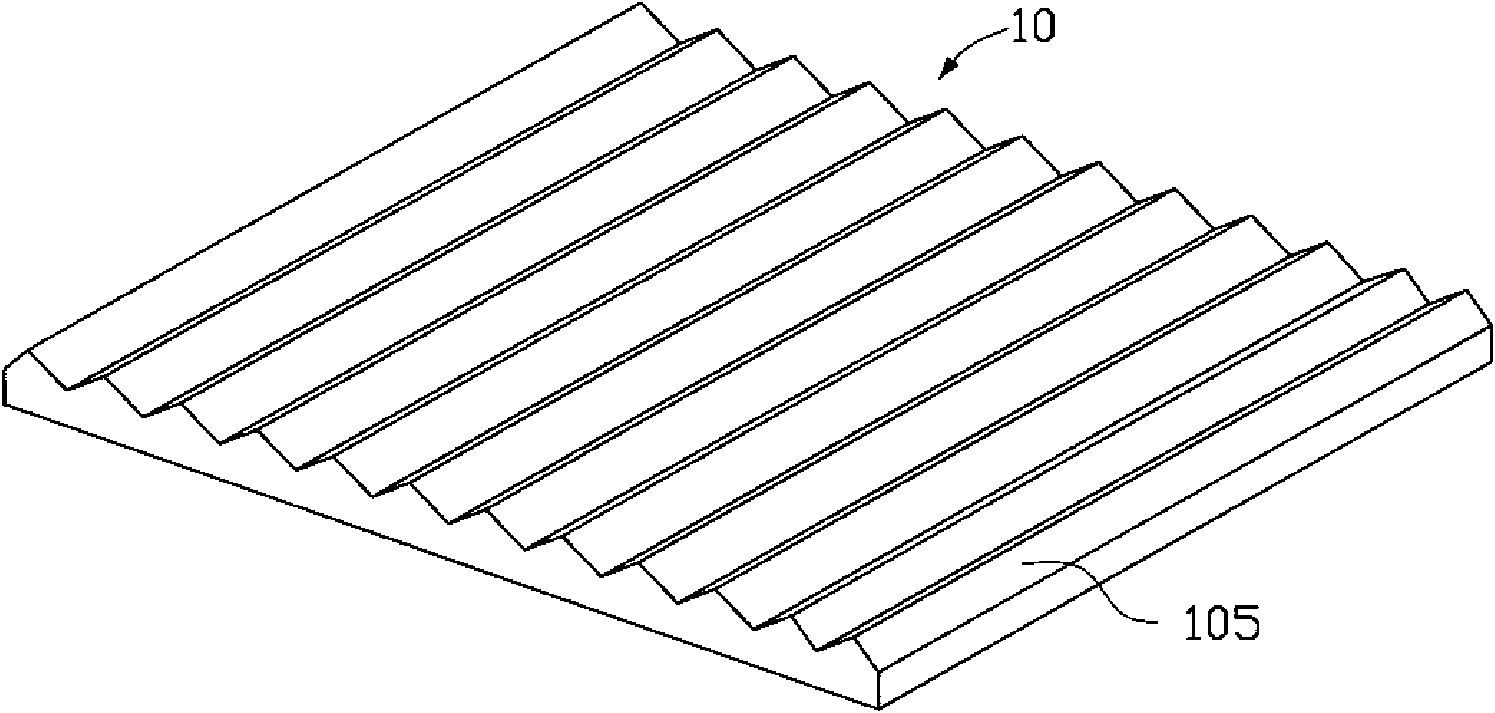

[0020] The backlight module and its optical board of the present invention will be further described in detail below with reference to the drawings and embodiments.

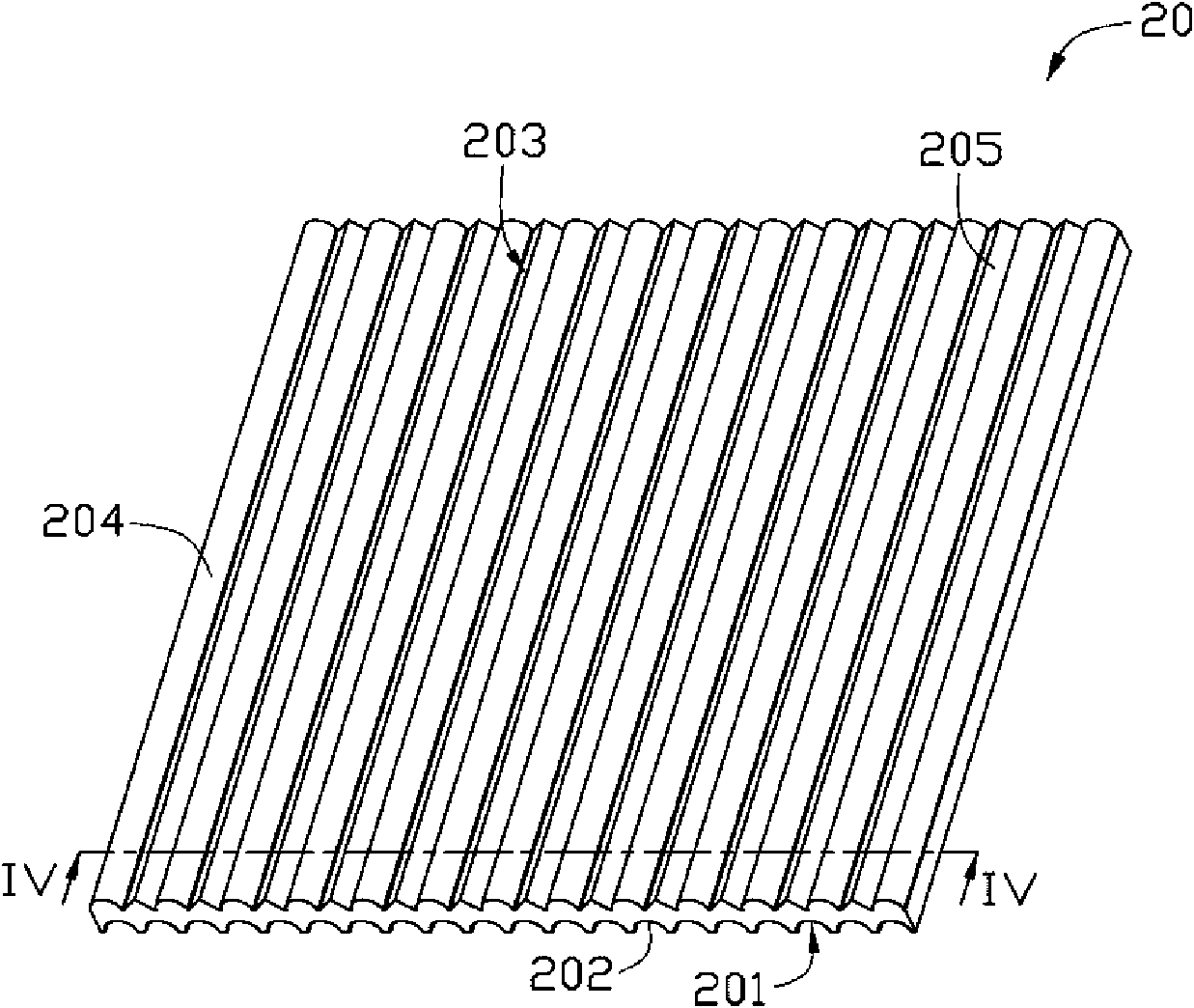

[0021] See image 3 and Figure 4 , shows the optical plate 20 according to the preferred embodiment 1 of the present invention, which is composed of a transparent body, and the transparent body includes a first surface 201 and a second surface 203 opposite to the first surface 201 . The first surface 201 has a plurality of elongated arc-shaped grooves 202 parallel to each other, and the second surface 203 is alternately provided with a plurality of elongated cylindrical protrusions 204 parallel to each other and a plurality of elongated V grooves parallel to each other. The elongated arc-shaped groove 202 on the first surface 201 is parallel to the elongated cylindrical protrusion 204 and the elongated V-shaped protrusion 205 on the second surface 203 .

[0022] In this embodiment, the cross-section of the elo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com