Special alloy-sheathed through earth wire for railway signal system and manufacturing method for special alloy-sheathed through earth wire

A technology that penetrates ground wires and railway signals. It is applied in the direction of circuits, conductors, and insulated cables. It can solve problems such as unstable electrical conductivity, unsatisfactory electrical conductivity, and soil and water pollution. It can improve corrosion resistance, improve smoothness, Strong corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

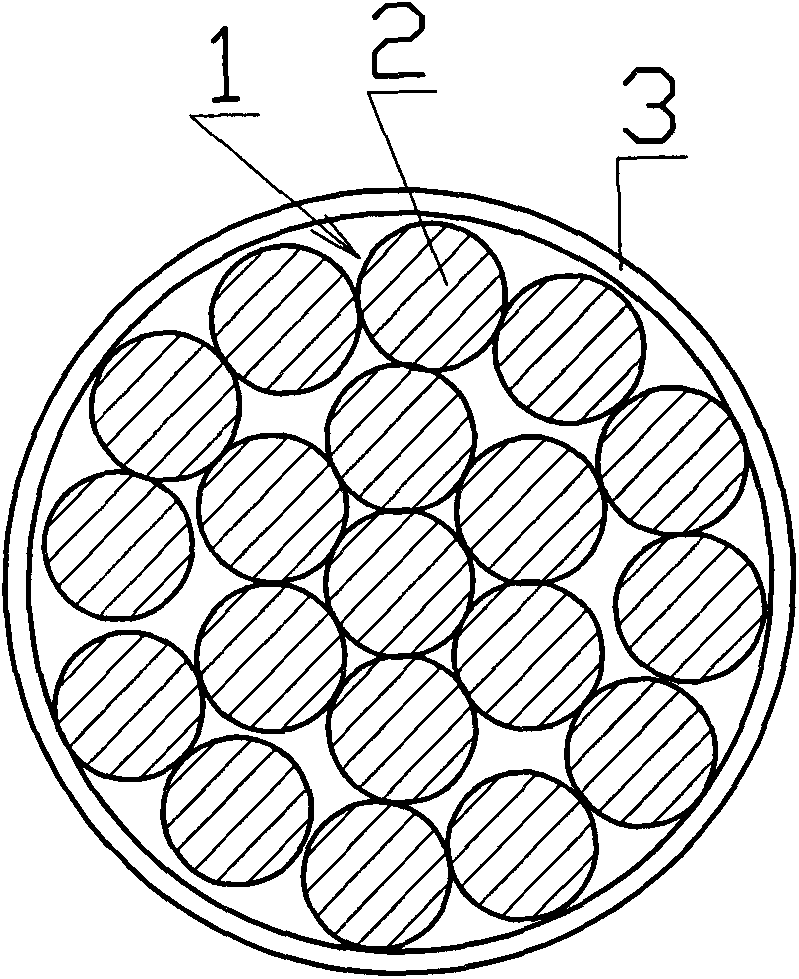

[0022] Below in conjunction with accompanying drawing, illustrate a kind of specific embodiment of the present invention in detail:

[0023] like figure 1 The special alloy through-ground wire for the railway signal system shown in the figure, the cable core 1 is formed by 7 soft round copper wires 2 arranged in a ring and twisted according to a certain pitch, and the soft round copper wires 2 are twisted in a layer-twisted or concentric arrangement . The cable core 1 is coated with a brass strip, and the brass strip coated on the cable core 1 forms a tubular outer sheath 3 , and the inner side of the outer sheath 3 is closely attached to the cable core 1 .

[0024] In order to reduce the resistance, the cable core 1 must be pressed tightly to reduce the gap between the soft round copper wires 2 to zero, and increase the contact force and contact surface between the cable core 1 and the outer sheath 3 . In order to stabilize the structure of the cable core 1 and reduce the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com