Heat Exchanger

A heat exchanger and heat exchange tube technology, which is used in the fields of HVAC, refrigeration, transportation, and automobiles, can solve the problems of uneven distribution of two-phase refrigerants, save time and resources, increase heat exchange area, and increase The effect of heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

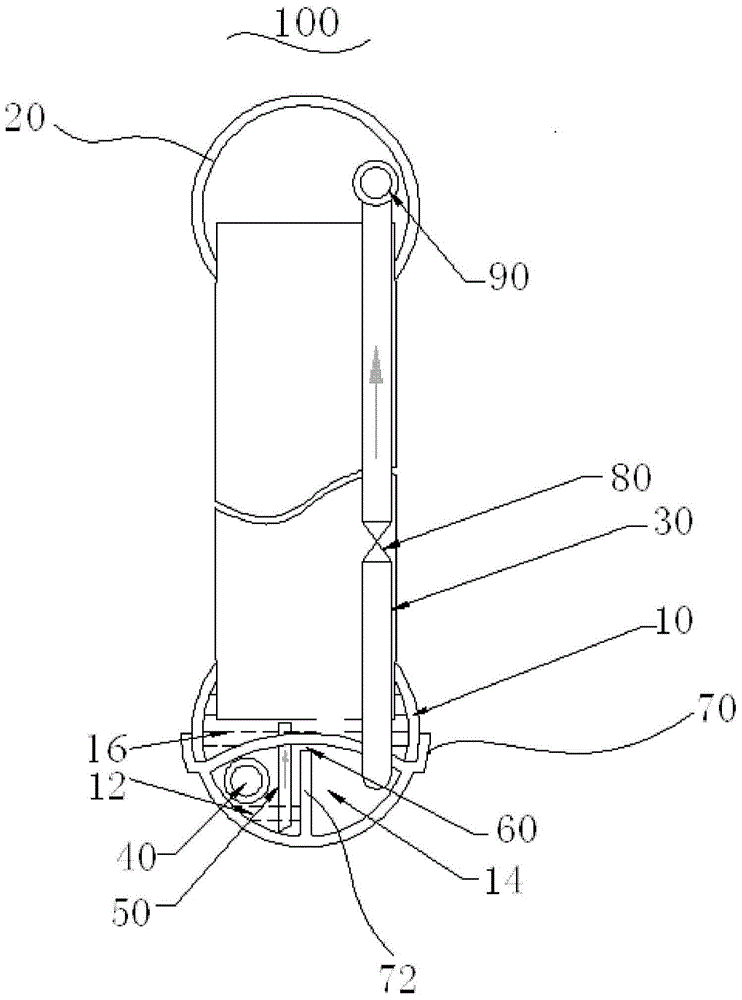

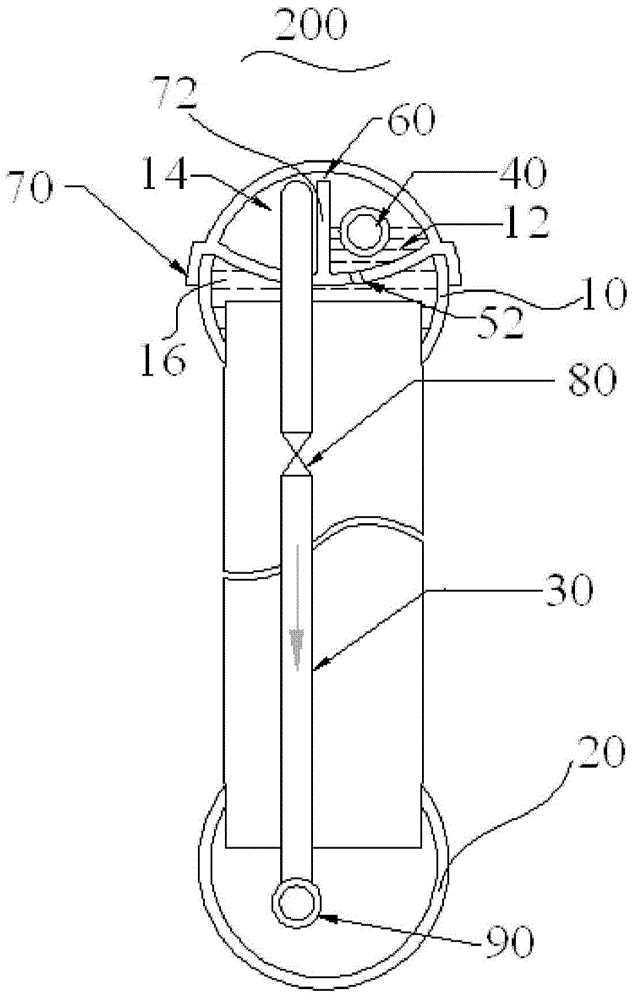

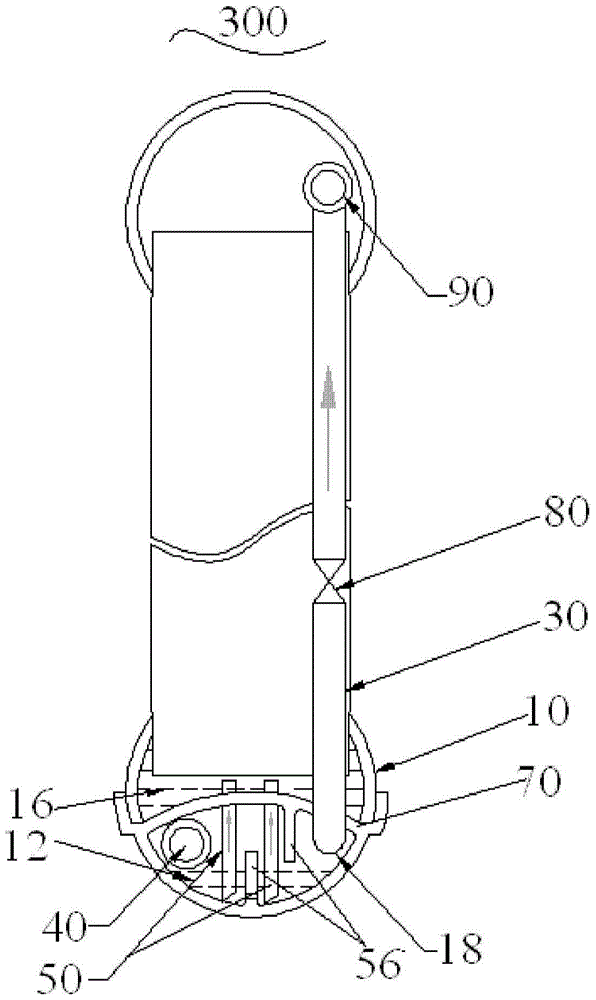

[0040] Through the following examples, combined with the attached Figure 1-6 , the technical solution of the present invention will be further specifically described. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0041] see figure 1, shows a side partial cross-sectional view of a heat exchanger 100 according to a first embodiment of the present invention. The heat exchanger 100 includes an inlet header 10 located at the lower part of the heat exchanger 100, an outlet header 20 located at the upper part of the heat exchanger 100, and at least one valve connected between the inlet header 10 and the outlet header 20. One or more heat exchange tubes (not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com