Low-cost HB400-grade wear-resisting steel and production method thereof

A production method and low-cost technology, which are applied to low-cost HB400 grade wear-resistant steel and its production field, can solve the problems of high strength and poor plasticity of martensitic wear-resistant steel, improve strength and wear resistance, and improve strength and plasticity, to solve the effect of high strength and poor plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

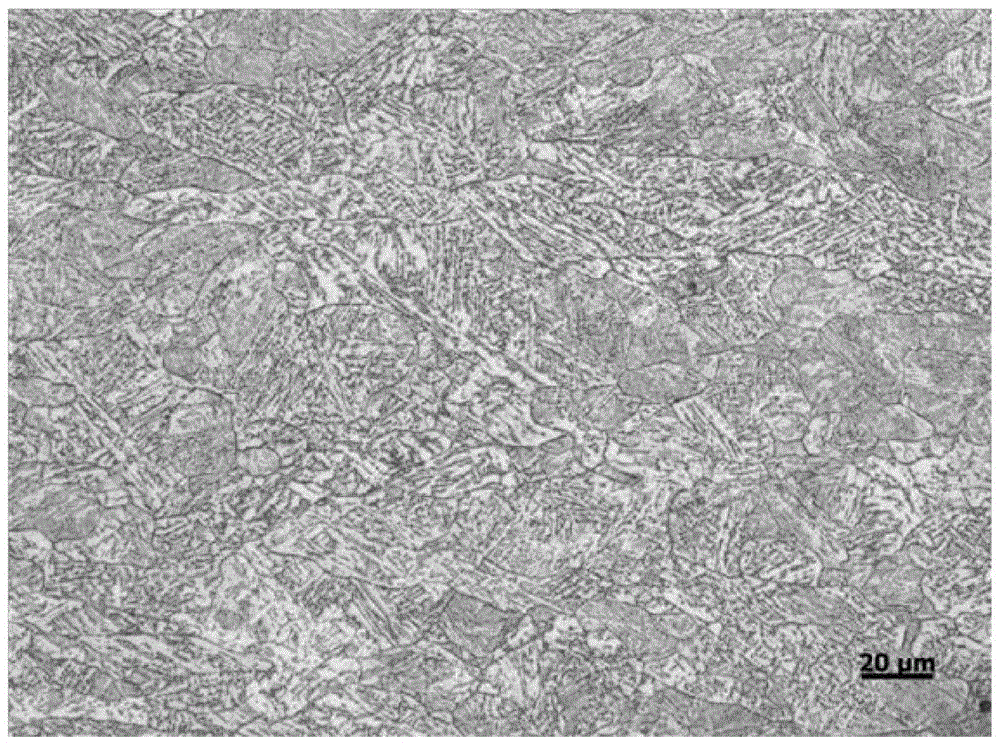

Image

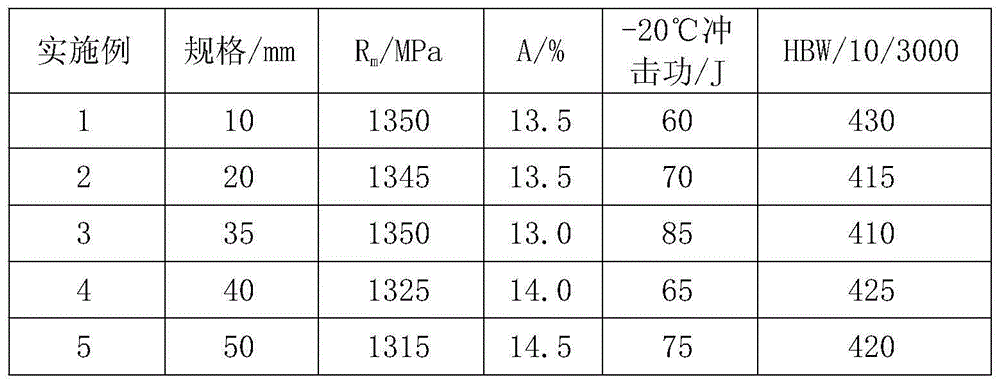

Examples

Embodiment 1

[0047] A low-cost manufacturing HB400 grade high-plastic high-strength wear-resistant steel and its processing method, its components and weight percentage content: C: 0.08%, Si: 0.20%, Mn: 1.60%, P: ≤ 0.015%, S: ≤0.015%, Cr: 0.65%, Nb: 0.02%, Ti: 0.005%, B: 0.001%, Als: 0.010%, the rest is Fe and trace impurity elements, CEV=C+Mn / 6+(V+Mo+ Cr) / 5+(Ni+Cu) / 15≤0.55.

[0048] Low manufacturing cost HB400 grade high plasticity high strength wear-resistant steel and its processing method, its steps:

[0049] 1) Smelting and continuous casting into billets;

[0050] 2) Heating the billet, the heating temperature is controlled at 1180-1240°C;

[0051] 3) Rolling process: the first stage rolling temperature is 1105°C, the first stage cumulative reduction rate is 68%, the second stage rolling temperature is 1020°C, the pass reduction rate is ≥15%, and the final rolling temperature is 920°C;

[0052] 4) On-line sub-temperature quenching, the starting cooling temperature is 765°C, the c...

Embodiment 2

[0056] A low-cost manufacturing HB400 high-plastic high-strength wear-resistant steel and its processing method, its components and weight percentage content: C: 0.09%, Si: 0.28%, Mn: 1.56%, P: ≤ 0.015%, S: ≤0.015%, Cr: 0.55%, Nb: 0.03%, Ti: 0.009%, B: 0.002%, Als: 0.018%, the rest is Fe and trace impurity elements, CEV=C+Mn / 6+(V+Mo+ Cr) / 5+(Ni+Cu) / 15≤0.55.

[0057] Low manufacturing cost HB400 grade high plasticity high strength wear-resistant steel and its processing method, its steps:

[0058] 1) Smelting and continuous casting into billets;

[0059] 2) Heating the billet, the heating temperature is controlled at 1180-1240°C;

[0060] 3) Rolling process: the first stage rolling temperature is 1119°C, the first stage cumulative reduction rate is 56%, the second stage rolling temperature is 1035°C, the pass reduction rate is ≥15%, and the final rolling temperature is 910°C;

[0061] 4) Sub-temperature quenching is carried out online, the starting cooling temperature is 710°...

Embodiment 3

[0065] A low-cost manufacturing HB400 grade high-plastic high-strength wear-resistant steel and its processing method, its components and weight percentage content: C: 0.13%, Si: 0.29%, Mn: 1.53%, P: ≤ 0.015%, S: ≤0.015%, Cr: 0.53%, Nb: 0.04%, Ti: 0.012%, B: 0.003%, Als: 0.028%, the rest is Fe and trace impurity elements, CEV=C+Mn / 6+(V+Mo+ Cr) / 5+(Ni+Cu) / 15≤0.55.

[0066] Low manufacturing cost HB400 grade high plasticity high strength wear-resistant steel and its processing method, its steps:

[0067] 1) Smelting and continuous casting into billets;

[0068] 2) Heating the billet, the heating temperature is controlled at 1180-1240°C;

[0069] 3) Rolling process: the first stage rolling temperature is 1135°C, the first stage cumulative reduction rate is 62%, the second stage rolling temperature is 1033°C, the pass reduction rate is ≥15%, and the final rolling temperature is 925°C;

[0070] 4) On-line sub-temperature quenching, the starting cooling temperature is 680°C, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com