Alkaline xylanase mutant and application thereof

A technology of xylanase mutation and xylanase, which is applied in the field of alkaline xylanase mutants, can solve problems such as limitations, and achieve the effects of improving whiteness, reducing environmental pollution, and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 Amplification of xylanase gene

[0019] According to the gene sequence in the public gene database, the codon of the synthetic gene was optimized and the alkaline xylanase gene XynA1 (sequence is SEQ ID NO: 2) was artificially synthesized, and the amino acid sequence encoded by it was SEQ ID NO: 1.

[0020] The alkaline xylanase gene XYNA1 fragment was cloned by PCR reaction, and the primers and reaction conditions were as follows:

[0021] Primer 1 (F): GCGCGAATTCGCTATTACTTCTAACGAGAT

[0022] Primer 2 (R): TAAAGCGGCCGCTTATCTAATTTCCAAGTAAT

[0023] The reaction conditions were: denaturation at 94°C for 30s, renaturation at 56°C for 30s, extension at 72°C for 1min, and after 30 cycles, incubation at 72°C for 10min. The results of agarose electrophoresis showed that the XynA1 gene was a 984bp fragment.

Embodiment 2

[0024] Example 2 Construction and Screening of Xylanase Mutants

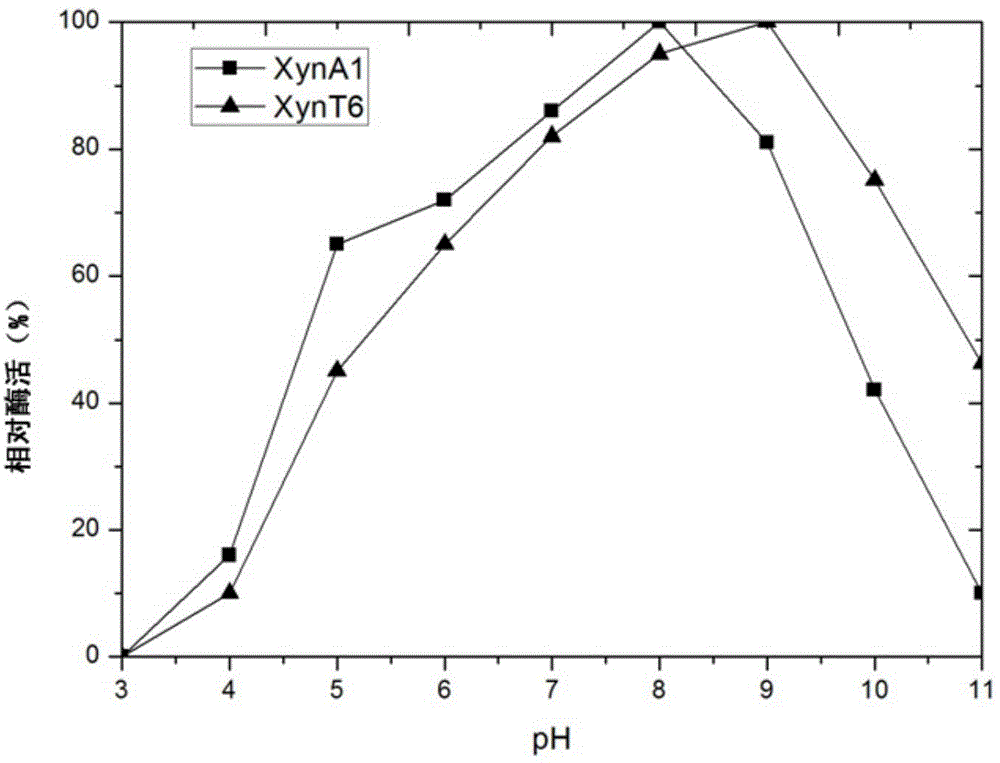

[0025] In order to improve the heat resistance and optimal reaction pH of xylanase XynA1 derived from Bacillus, a large number of mutations of the enzyme were screened by directed evolution technology.

[0026] Using the XynA1 gene as a template, use primers 1 and 2 to perform PCR amplification with the GeneMorph II Random Mutation PCR Kit (Stratagene), recover the PCR product from the gel, perform enzyme digestion with EcoRI and NotI, and then ligate it to the pET21a vector after the same enzyme digestion , transformed into Escherichia coli BL21(DE3), spread on LB+Amp plates, and culture them upside down at 37°C. After the transformants appeared, pick them one by one with a toothpick to a 96-well plate, and add 150ul of 0.1mM IPTG to each well. LB+Amp culture medium, cultured at 37°C and 220 rpm for about 6 hours, centrifuged to discard the supernatant, resuspended the bacteria with pH 8.0 buffer, and repeatedl...

Embodiment 3

[0030] Example 3 Construction of Pichia pastoris engineering strain

[0031] The xylanase mutant gene XynT6 fragment cloned above was connected to the expression vector pPIC9K through the EcoR I and Not I sites to construct the expression vector pPIC9K-XynT6.

[0032] The expression plasmid pPIC9K-XynT6 was linearized with Sal I, and the linearized fragment of the expression plasmid was transformed into Pichia pastoris GS115 by electroporation, and the recombinant strain of Pichia pastoris GS115 / pPIC9K-XynT6 was obtained by screening on the MD plate, and then mixed with different concentrations of Multi-copy transformants were screened on Geneticin YPD plates.

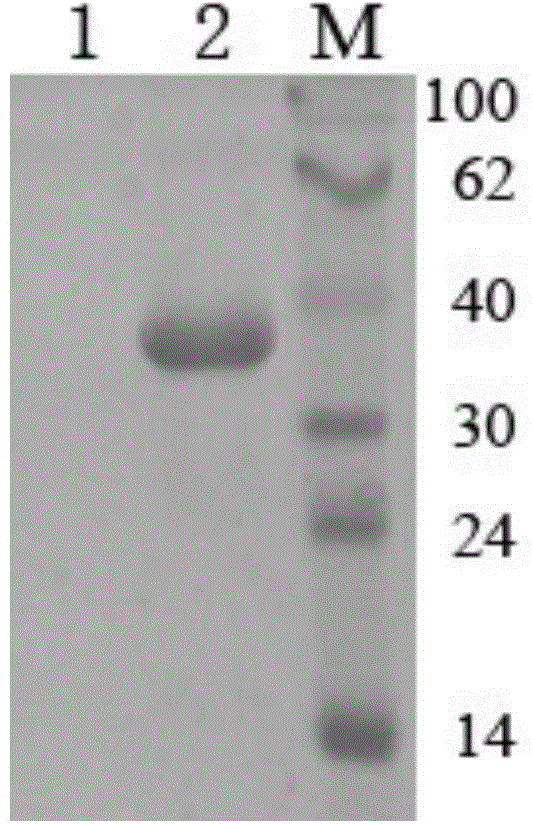

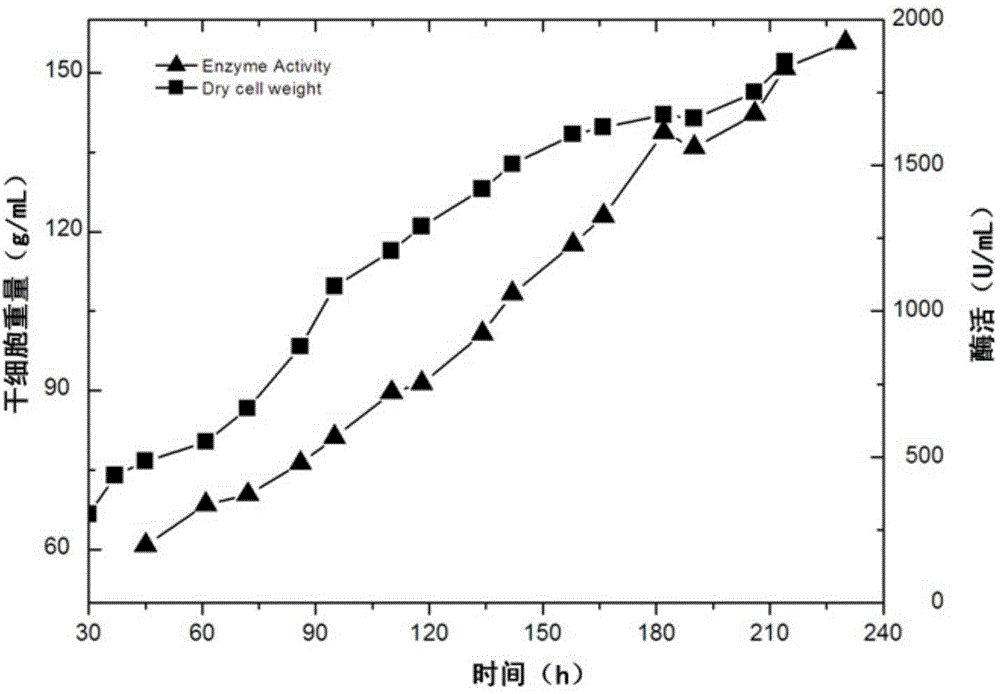

[0033] One transformant named Pichia pastoris XynT6 (Pichia pastoris XynT6), was transferred to BMGY medium, 30°C, 250rpm shaking culture for 1d; then transferred to BMM medium, 30°C, 250rpm shaking culture; adding 0.5 % methanol, induced expression for 4 days; centrifuged to remove the bacteria, to obtain the ferment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com