Modified friction particle for friction material and preparation method thereof

A technology of friction particles and friction materials, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of lack of elasticity, inability to take into account porosity, poor high temperature performance, etc., to reduce the impact of friction materials and noise generation, The effect of avoiding high temperature brake failure and reducing braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Modified particle-1

[0041] The proportion is: alumina 10% + zirconia 10%, American Pama black powder 10% + Dutch D powder 15%, manganese sulfide 6% + zinc sulfide 9% + copper sulfide 4%, unexpanded silver white leech Stone powder 3% + graphite 4%, nitrile rubber 6% + styrene butadiene rubber 12%, liquid resin 3% + nitrile latex 2%, performance regulator 5%, rubber additive 1%. Total 100%.

[0042] The preparation method of modified granules (the same below): After pre-mixing all raw materials, add rubber kneader for rubber kneading, after initial curing, open and coarsely crush granules with a size of 3-5 cm. Preliminary vulcanization is maintained for 3 hours in the hot air furnace without pressure, and then crushed into 1-3mm particles, which is the product.

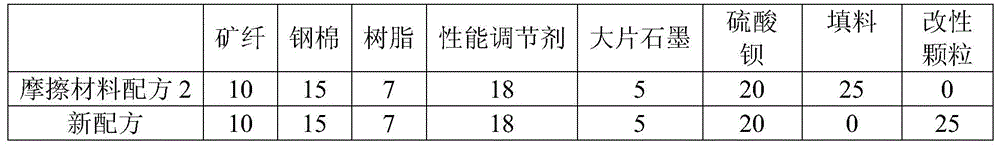

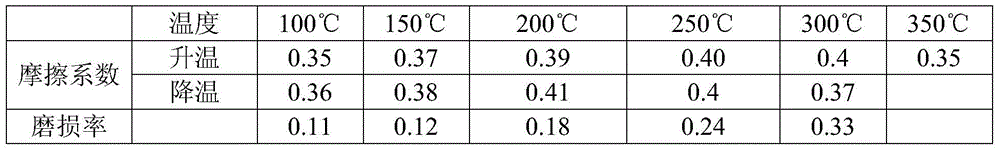

[0043] The modified particles obtained above were added to friction material formula 2 as a substitute for conventional fillers, so that the modified particles accounted for 25% of the total mass...

Embodiment 2

[0051] Embodiment 2: Modified particle-2

[0052] Formula: alumina 18% + zirconia 12%, American Perma black powder 10% + Dutch D powder 10%, manganese sulfide 4% + zinc sulfide 4% + copper sulfide 2%, unexpanded silver white vermiculite powder 7 % + graphite 8%, nitrile rubber 5% + styrene butadiene rubber 7%, liquid resin 2% + nitrile latex 1%, performance regulator 9.5%. Rubber additives 0.5%. Total 100%.

[0053] Add the modified particles obtained above as a substitute for conventional fillers into the friction material formula 2, so that the modified particles account for 25% of the total mass of raw materials, and make brake linings according to the conventional pressing method, at a constant speed according to the GB5763-2008 standard Test according to 4 categories on the testing machine, and the results are shown in Table 4. Other physical performance tests are shown in the remarks.

[0054] Table 4: Constant speed test Standard: GB5763-2008

[0055]

[0056] N...

Embodiment 3

[0058] Embodiment 3: Modified particle-3

[0059] Formula: alumina 12% + zirconia 8%, American Perma black powder 15% + Dutch D powder 15%, manganese sulfide 4% + zinc sulfide 4% + copper sulfide 3%, unexpanded silver white vermiculite powder 3 % + graphite 5%, nitrile rubber 7% + styrene butadiene rubber 9%, liquid resin 2.5% + nitrile latex 1.5%, performance modifier 10%, rubber additive 1%. Total 100%.

[0060] Add the modified particles obtained above as a substitute for conventional fillers into the friction material formula 2, so that the modified particles account for 25% of the total mass of raw materials, and make brake linings according to the conventional pressing method, at a constant speed according to the GB5763-2008 standard According to 4 types of tests on the testing machine, the results are shown in Table 5. Other physical performance tests are shown in the remarks.

[0061] Table 5: Constant speed test Standard: GB5763-2008

[0062]

[0063] Note: har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com