Simplified preparation method of polyurethane hydrogel

A hydrogel and polyurethane technology, which is applied in the field of polyurethane hydrogel preparation, can solve the problems of cumbersome preparation process and long time consumption, and achieve the effects of simple preparation process, shortened reaction time, and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

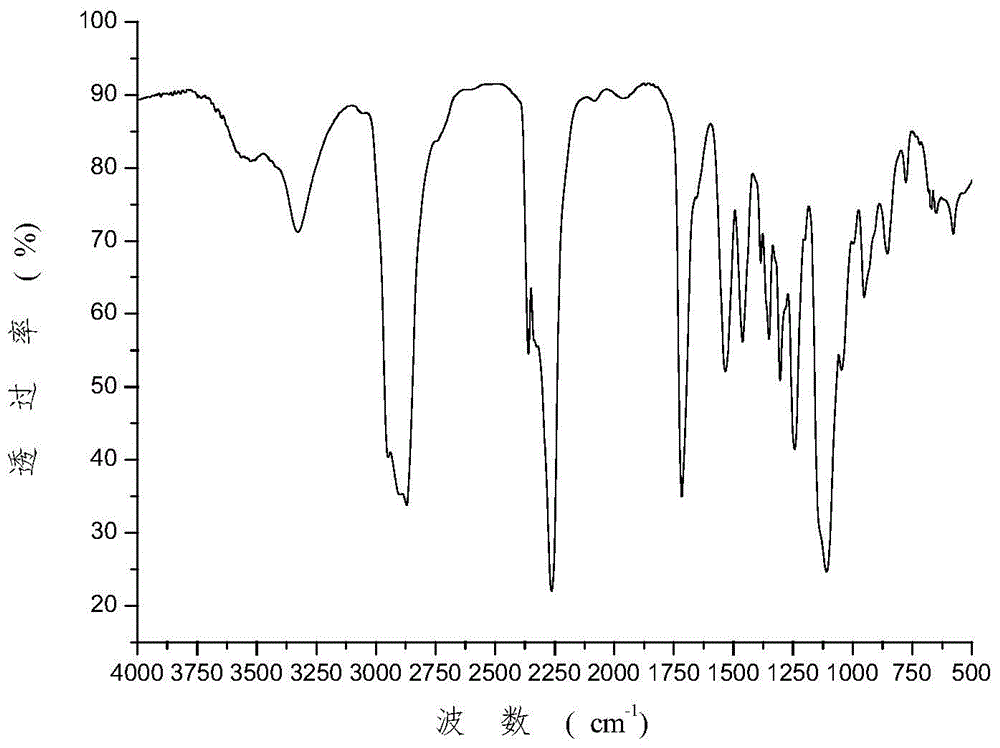

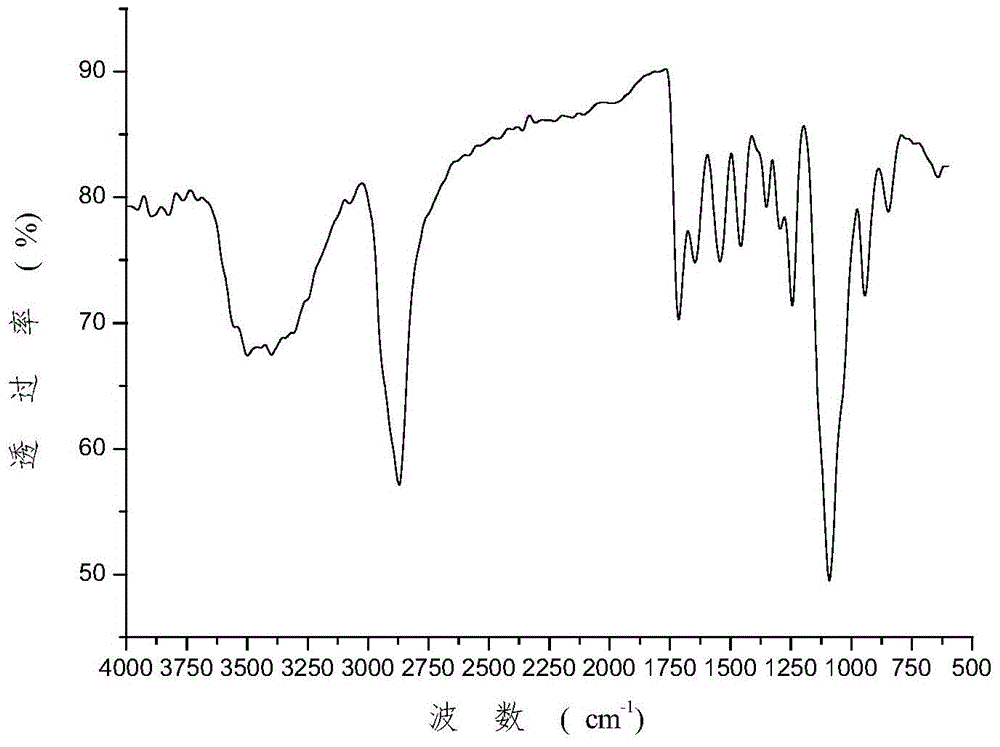

Image

Examples

Embodiment 1

[0033] (1) Synthesis of polyurethane prepolymer: In terms of mass fraction, first add 60 parts of polytetrahydrofuran diol into a 250mL three-necked flask, heat up to 125°C; add 2 parts of 1,4-butanediol chain extender, Keep the vacuum at 0.08MPa. After dehydration for 3 hours, place it to lower the temperature to 25°C; add the dehydrated polytetrahydrofuran diol to 10 parts of isophorone diisocyanate in two times, and the time interval between two additions is 40 minutes; after the addition, control the temperature and react at 100°C for 2 hours, and use the di-n-butylamine titration method to measure the mass content of -N=C=O in the prepolymer; when the actual measured value is close to the theoretical value, vacuum defoaming , sealed and kept for later use. After testing, the mass content of isocyanate groups is 0.2510g / 100g, and the molar concentration is 0.0060mol / 100g.

[0034] (2) Preparation of polyurethane hydrogel: In terms of mass fraction, add 1 part of polyureth...

Embodiment 2

[0040] (1) Synthesis of polyurethane prepolymer: In terms of mass fraction, first add 40 parts of polycastor oil adipate polyol into a 250mL three-necked flask, heat up to 125°C; add 2.5 parts of glycerol chain extender , the vacuum degree is kept at 0.06MPa, after dehydration for 2.5 hours, place it to lower the temperature to 25°C; add the dehydrated polyethylene glycol to 30 parts of HDI trimer in 8 times, and the time interval between 8 times of addition is 10 minutes ; After the addition, control the temperature and react at 80°C for 3 hours, and use the di-n-butylamine titration method to measure the mass content of -N=C=O in the prepolymer; when the actual measured value is close to the theoretical value, vacuum defoaming and sealing Save for later. The mass content of isocyanate group is 0.9896g / 100g, and the molar concentration is 0.0236mol / 100g;

[0041] (2) Preparation of polyurethane hydrogel: In terms of mass fraction, add 5 parts of polyurethane prepolymer to 50...

Embodiment 3

[0043] (1) Synthesis of polyurethane prepolymer: In terms of mass fraction, first add 50 parts of polyethylene adipate diol into a 250mL three-necked flask, stir evenly, heat up to 100°C; add 2 parts of trihydroxy Methyl propane chain extender, the vacuum degree is kept at 0.04MPa, after dehydration for 2.5 hours, place it to lower the temperature to 60°C; add the dehydrated polyethylene adipate glycol in 3 times to 20 parts of In 1,6‐hexamethylene diisocyanate, the time interval between 3 additions is 20 minutes; after the addition, the temperature is controlled at 80°C for 3 hours, and the -N=C= The mass content of O; when the actual measured value is close to the theoretical value, vacuum defoaming, sealed and preserved for future use. The mass content of isocyanate groups is 3.4860g / 100g, and the molar concentration is 0.0830mol / 100g.

[0044] (2) Preparation of polyurethane hydrogel: In terms of mass fraction, 10 parts of polyurethane prepolymers are added to 80 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com