Synthetic method for high-performance water-absorbent resin processed by electron beam irradiation

An electron beam irradiation and synthesis method technology, applied in the field of irradiation processing, can solve problems such as low gamma ray dose rate, product performance impact, safety risks, etc. Simple control, simple way to control the reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for synthesizing a high-performance water-absorbing resin processed by electron beam irradiation, comprising the following steps:

[0040](1) Add 20 to 80 parts by weight of polymerized monomers, 0.001 to 1 parts by weight of crosslinking agent, and 0.01 to 5 parts by weight of other additives into the reactor, and mix them uniformly to obtain a liquid to be polymerized, wherein the polymerized monomers It is acrylic acid or methacrylic acid with a neutralization degree of 50-90%. These two monomers have a wide range of sources, low prices, and high liquid absorption ratio; the secondary monomer is 2-acrylamide-2-methylpropanesulfonic acid , one of acrylamide, these two non-ionic double bond-containing monomers can quickly absorb physiological saline and enhance the pressure-resistant liquid absorption after liquid absorption; while the proportion of acrylic acid is higher than 80% is the preferred solution, and more It is beneficial to i...

Embodiment 1

[0068] (1) Put 1,000 parts of acrylic acid into a mixing tank, neutralize with 30% sodium hydroxide solution to a neutralization degree of 77%, add 50 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, add N,N- 2 parts by weight of methylene bis(meth)acrylamide, 1 part by weight of polyethylene glycol diacrylate, 10 parts by weight of sodium dodecylbenzenesulfonate, and 10 parts by weight of ethanol, and stir evenly to obtain a material solution to be polymerized;

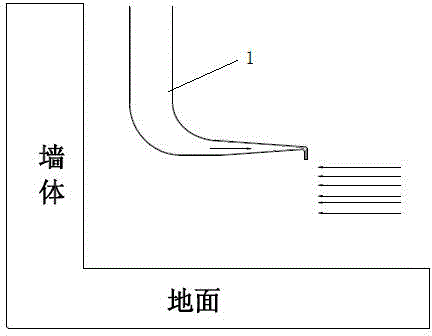

[0069] (2) The material liquid prepared in (1) is transported by a chemical pump to the thinner to flow down, and irradiated by an electron beam parallel to the ground, so that the absorbed dose of the material liquid reaches 15kGy, and the gel sheet is obtained;

[0070] (3) Cut the gel plate obtained in (2) into 3mm small rubber particles by a cutting machine; dry at 80-180°C to obtain semi-finished granules.

[0071] (4) Add 100 parts of the semi-finished granules obtained in (3) to 5% surface cross-l...

Embodiment 2

[0073] (1) Put 1,000 parts of acrylic acid into a mixing tank, neutralize with 30% sodium hydroxide solution to a neutralization degree of 77%, add 50 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, add N,N- 3 parts by weight of methylene bis(meth)acrylamide, 0.3 parts by weight of polyethylene glycol diacrylate, 5 parts by weight of sodium lauryl sulfate, and 8 parts by weight of pentane, stirred evenly to obtain a material solution to be polymerized;

[0074] (2) The material liquid prepared in (1) is transported by a chemical pump to the thinner to flow down, and irradiated by an electron beam parallel to the ground, so that the absorbed dose of the material liquid reaches 12kGy, and the gel sheet is obtained;

[0075] (3) Cut the gel plate obtained in (2) into 3mm small rubber particles by a cutting machine; dry at 80-180°C to obtain semi-finished granules.

[0076] (4) Add 6% of the surface cross-linking solution to the semi-finished granules obtained in (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com