Rectification method for separating ethylene glycol and 1,2-butanediol

A technology of ethylene glycol and butanediol, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of long process, low investment and short process of rectification and separation, and reduce operating costs , Simplify the process flow and reduce the cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

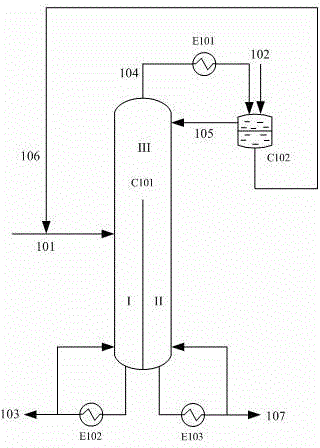

Embodiment 1

[0030] according to figure 1 In the body of the dividing wall distillation tower shown, the total number of theoretical plates is 60, and the number of theoretical plates in the dividing wall section is 40. The partitions of the dividing wall section are placed along the axial direction, and the raw material inlet is located on the side of the dividing wall section and counted from top to bottom. At the 10th theoretical plate, the inlet of the entrainer is located at the 5th theoretical plate from top to bottom in the public rectification section. Raw materials composed of 85% ethylene glycol and 15% 1,2-butanediol by weight are added from the raw material import, and the entrainer (substituent R 1 , R 2 , R 3 and R 4 Respectively: -H, -H, -CH 3 ,-(CH 2 ) 4 CH 3 ) from the entrainer inlet, the mol ratio of ethylene glycol in the entrainer to the raw material is 1.5:1, the operating pressure of the dividing wall rectification column is normal pressure, the reflux ratio i...

Embodiment 2

[0033] according to figure 1 The body of the dividing wall rectification column shown has a total number of theoretical plates of 45 and a theoretical plate number of 30 in the dividing wall section. At the 8th theoretical plate, the inlet of the entrainer is located at the 5th theoretical plate from top to bottom in the public rectification section. Raw materials composed of 60% ethylene glycol and 40% 1,2-butanediol by weight are added from the raw material import, and the entrainer (substituent R 1 , R 2 , R 3 and R 4 Respectively: -H, -H, -CH 3 ,-(CH 2 ) 4 CH 3 ) from the entrainer inlet, the entrainer and the mol ratio of ethylene glycol in the raw material are 1.5:1, the operating pressure of the dividing wall rectification column is 50KPa, the reflux ratio is 25, and the liquid phase distribution ratio is 2 (I / II), the temperature at the top of the tower is 156°C, the temperature on the feed side of the dividing wall section of the tower is 185°C, and the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com