Production process of microcrystalline foam fireproof and thermal insulation materials by using aeolian sand and peat

A technology of fire prevention and heat preservation and microcrystalline foaming, which is applied in the production process of microcrystalline foaming fireproof and heat preservation materials using aeolian sand and peat, which can solve the problems of environmental pollution of aeolian sand, optimize the environment and save production Cost, the effect of speeding up the firing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

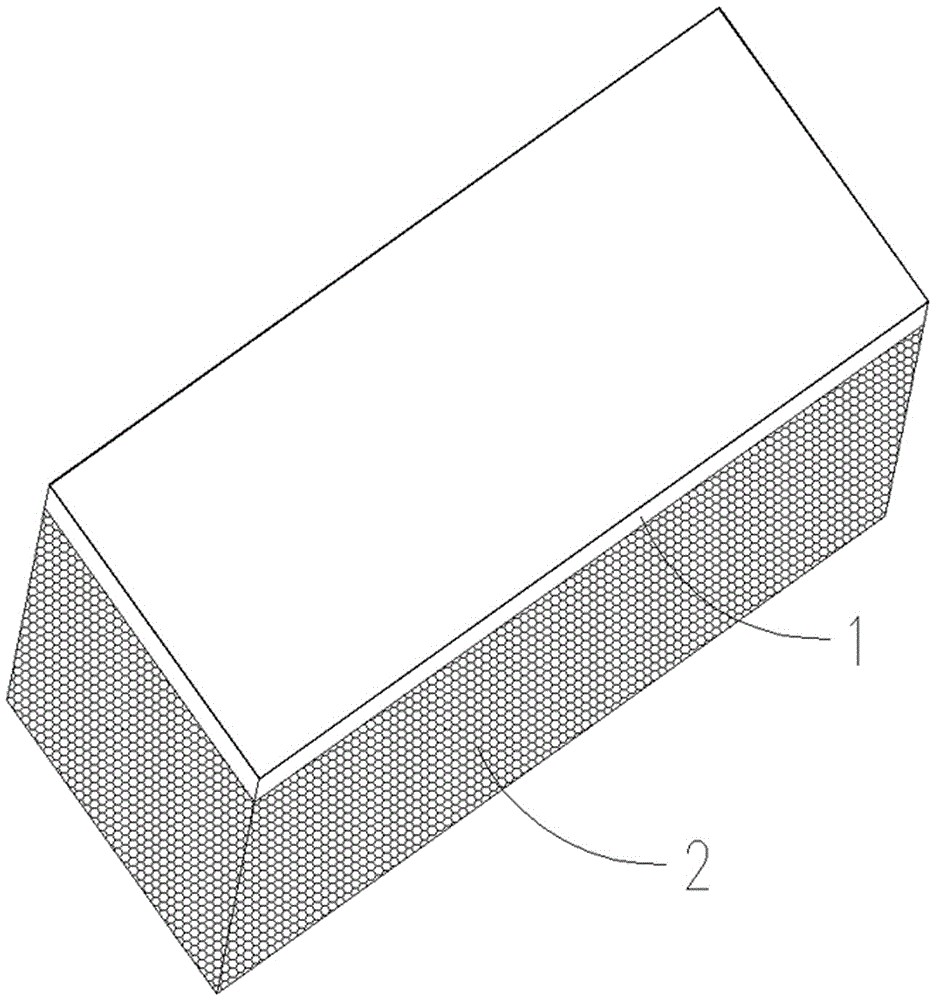

[0029] Embodiment 1: A microcrystalline foamed fireproof and thermal insulation board produced by a production process of using aeolian sand and peat to produce microcrystalline foamed fireproof and thermal insulation materials, characterized in that: the raw materials are mixed once with microcrystalline particles, peat and limestone fine powder It is a microcrystalline foam fireproof and thermal insulation material board formed by one-piece firing, and its internal structure is honeycomb.

[0030] The microcrystalline foamed fireproof and thermal insulation board is characterized in that: the thickness of the board body is 3-600 mm.

Embodiment 2

[0031] Embodiment 2: as shown in the accompanying drawing, a kind of double-layer microcrystalline foamed fire-proof and heat-preservation plate that utilizes aeolian sand and peat to produce the manufacturing process of microcrystalline foam fire-proof and heat-insulating material is made of wind-blown sand, peat and limestone fine powder The microcrystalline foamed fire-proof and thermal insulation material board is made of mixed raw materials at one time. The board has a 3-600mm thick double-layer structure; The structure is dense; the other side is made of 3-600mm thick microcrystalline foaming mixed material 2, and the interior is honeycomb.

[0032] The production process of the double-layer microcrystalline foamed fireproof and thermal insulation board includes raw material preparation, cloth, firing, and finished product processing. It is characterized in that the cloth process consists of the following steps:

[0033] A. Load raw materials into different silos of the ...

Embodiment 3

[0037] Embodiment 3: According to the combined content of raw materials (percentage by weight), the microcrystalline foamed fireproof and thermal insulation board made of 70% aeolian sand, 20% peat, and 10% limestone has a dry density of 500kg / cubic. Heat conduction gas number 0.20 (350 degrees); compressive strength 10MPa; combustion performance A1 standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com