Smoldering device for fast and low-temperature combustion of carbon powder in biomass briquette fuel combustion device

A technology of forming fuel and combustion device, which is applied in the direction of combustion chamber, control combustion, combustion method, etc., to achieve the effect of avoiding excessive local temperature, convenient adjustment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

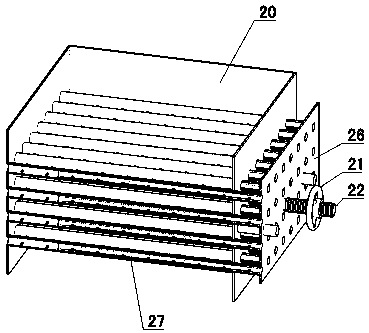

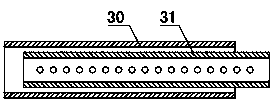

[0037] Such asfigure 1 Shown: the smoldering pool 20 is a rectangular parallelepiped casing with open upper and lower ends, and the inwall of the smoldering pool 20 is provided with an insulating layer, and the insulating layer is a refractory material. The right side of smoldering pool 20 is provided with smoldering pool air intake box 25, and smoldering pool air intake box 25 is a cuboid casing, and smoldering pool air intake box 25 is connected with smoldering pool air intake pipe 24, and smoldering pool air intake pipe 24 is used for connecting fan. The smoldering pool air intake pipe 24 is provided with an air volume regulating unit, and the air volume regulating unit is the smoldering pool air intake valve 23 . The left side of the smoldering pool 20 is provided with a smoldering pool outlet box 28, and the smoldering pool outlet box 28 is also a cuboid casing, and the smoldering pool outlet box 28 is connected with a smoldering pool outlet pipe 29, and the smoldering po...

Embodiment 2

[0074] Such as Figure 12 Shown: the difference between embodiment 2 and embodiment 1 is: the smoldering pool air intake box 25 includes the smoldering pool combustion-supporting box and the smoldering pool cooling box, and the smoldering pool cooling box and the smoldering pool combustion-supporting box are set independently. Air inlet pipe 27 comprises combustion-supporting air inlet pipe 41 and cooling air inlet pipe 42, and combustion-supporting air inlet pipe 41 and cooling air inlet pipe 42 are all arranged in the smoldering pool 20, and the right end of combustion-supporting air inlet pipe 41 and the smoldering pool combustion-supporting The box is communicated, and the right end of the cooling air inlet pipe 42 is communicated with the cooling tank of the smoldering pool. The left ends of the combustion-supporting air inlet pipe 41 and the cooling air inlet pipe 42 are all communicated with the gas outlet box 28 of the smoldering pool. The combustion-supporting air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com