Backflow incense and preparation method thereof

A technology of backflow incense and sandalwood, which is applied in the direction of medical formulas, medical preparations with no active ingredients, and medical preparations containing active ingredients. Effects of improving adhesion performance, reducing delamination, improving drying performance and moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

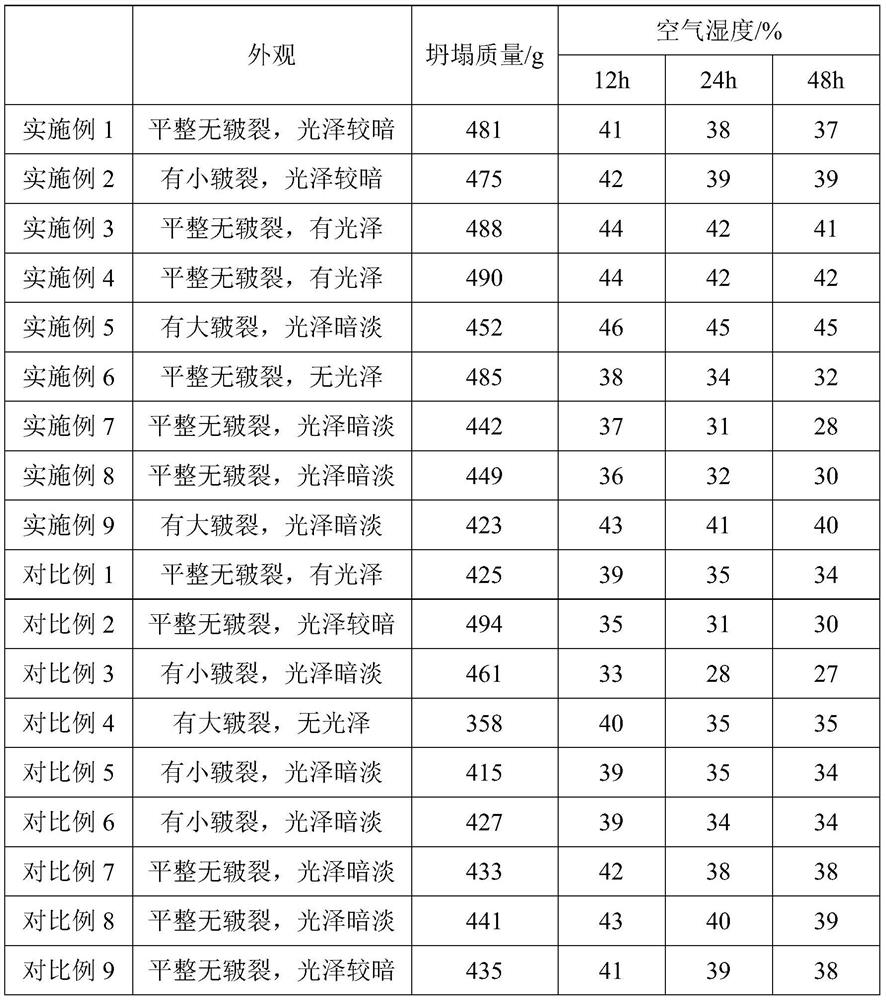

[0024] Table 1 shows the parts by weight of the raw materials of backflow incense in Examples 1-6.

[0025] The parts by weight of each raw material of backflow incense in the embodiment 1-6 of table 1

[0026] Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Ai Rong 55 60 58 56 56 57 sandalwood 5 10 8 6 7 8 Chinese herbal medicine powder 30 40 38 32 31 38 adhesive 10 15 12 10 10 15 desiccant 5 10 7 6 10 5

[0027] In the present embodiment 1-6, the Chinese herbal medicine powder includes Gansong, Peilan, Shichangpu, mint, ginger and tangerine peel, and the mixing ratio of Gansong, Peilan, Shichangpu, mint, ginger and tangerine peel is 1:0.8: 0.1: 0.05: 0.5; Chinese herbal medicine powder is prepared by the following steps: adding gansong, perlan, calamus, mint, ginger and tangerine peel into water, and boiling at a ratio of solids to water 1:7 until the ratio of solids to water is 1: A...

Embodiment 7

[0032] The difference between this embodiment 7 and embodiment 3 is that in embodiment 7, the binder is a mixture of coconut flour, starch and lotus root flour in parts by weight in a mixing ratio of 1:3:1.

Embodiment 8

[0034] The difference between this embodiment 8 and embodiment 3 is that in embodiment 8, the binder is a mixture of coconut flour, starch and lotus root powder in a mixing ratio of 1:1:3 in parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com