Boiler equipment capable of improving burn-off rate of pulverized coal and reducing NOx generation amount

A technology of boiler equipment and burnout rate, which is applied in the fields of clean coal combustion and low-carbon energy saving, and can solve problems such as meaninglessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

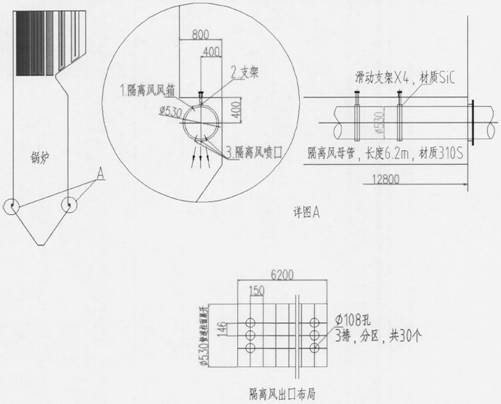

[0011] For a clearer understanding of the technical content of the present invention, the following figure 1 Take the proposed plan as an example for illustration:

[0012] figure 1 According to the transformation plan of a kind of boiler with tangential combustion at four corners according to the idea of the present invention, the object of specific investigation is a 330MW pulverized coal boiler with tangential combustion at four corners, which adopts π-shaped layout and staged combustion.

[0013] A is where the water-cooled wall of the front and rear walls of the boiler is turned to the outside of the furnace. As can be seen from the partially enlarged detailed drawing A, the entire water-cooled wall is turned out to the outside of the furnace by a distance of 800mm, and then connected to the water-cooled wall of the cold ash hopper. 1 is an isolation bellows, which is an air injection component. The width of the front and rear walls of the four-corner tangential boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com