Method for improving effective thermal efficiency of engine and power transmission mechanism prepared through same

A technology of power transmission and thermal efficiency, applied in the direction of machine/engine, mechanical equipment, etc., can solve the problem of small improvement of the effective thermal efficiency of the engine, and achieve the effect of less parts, large power improvement, and favorable combustion and compression ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

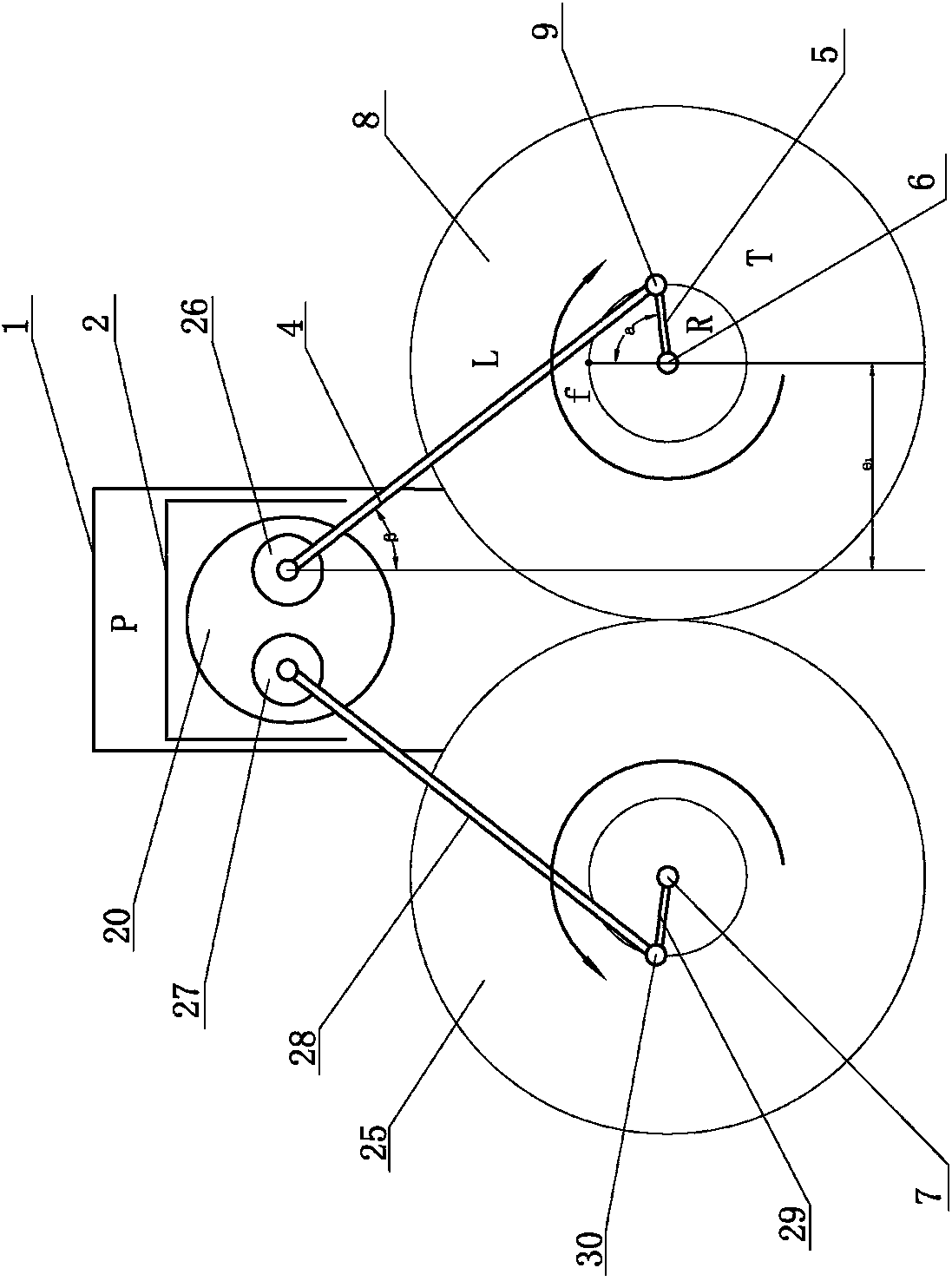

[0074] Embodiment 1: it has the first cylinder 1, the first piston 2 is installed in the first cylinder 1, the circular slider 20 is installed on the first piston, the first pin shaft 26 and the second pin shaft 27 are installed on the circular slider 20, the first The pin shaft 26 is connected with one end of the first crank connecting rod 4, the other end of the first crank connecting rod 4 is connected with one end of the first crank 5 through the first crank shaft 9, and the other end of the first crank 5 is connected with the first crankshaft 6, The first crankshaft 6 is fixedly connected to the first synchronous gear 8, and the distance between the axis of the first crankshaft 6 and the axis of the connecting end of the first pin 26 and the first crank connecting rod 4 is the first eccentricity e 1 The second pin shaft 27 is connected with one end of the second connecting rod 28 of the crank, the other end of the second crank connecting rod 28 is connected with one end of...

Embodiment 2

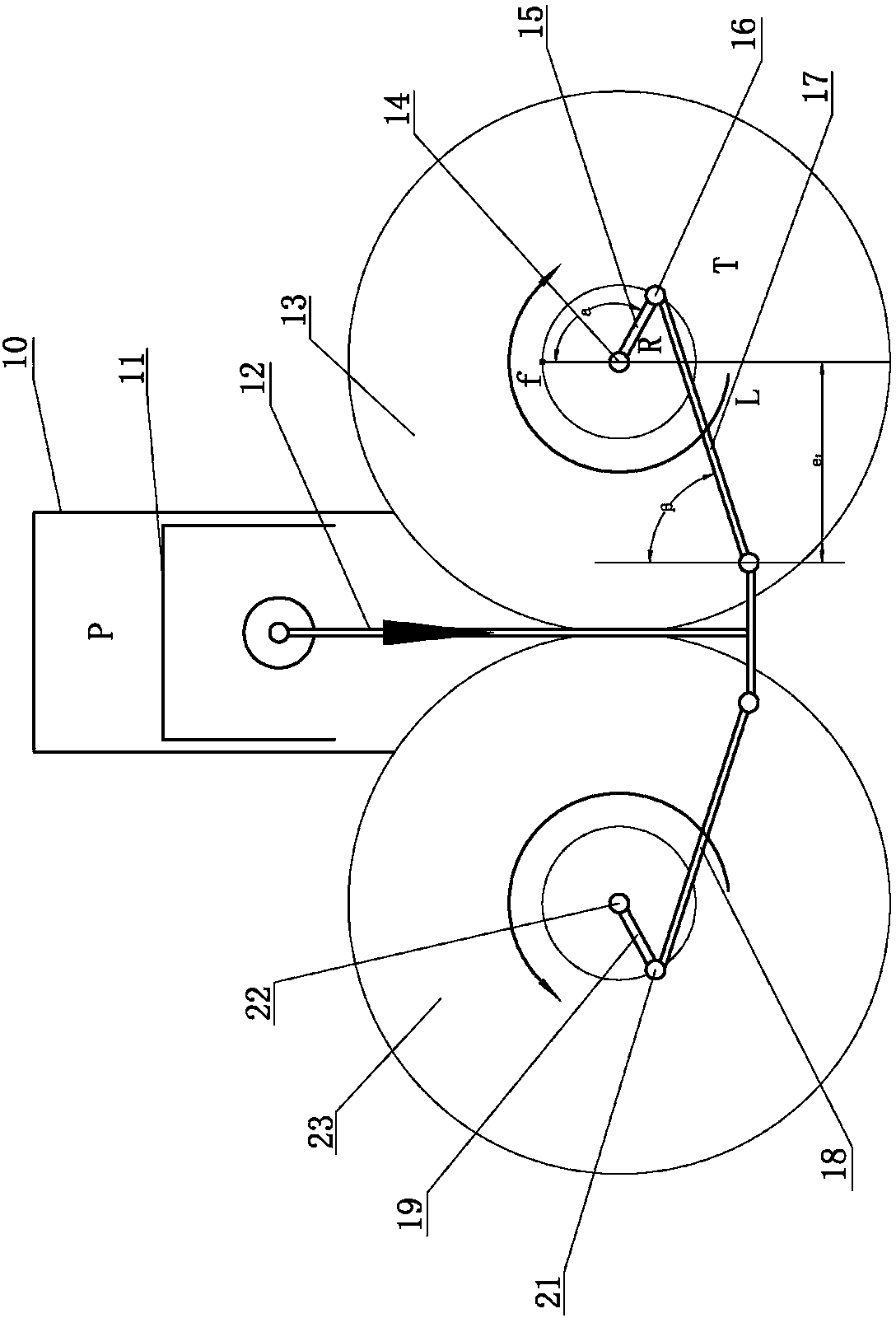

[0075] Embodiment two: it has a second cylinder 10, a second piston 11 is installed in the second cylinder 10, the second piston 11 is connected with one end of the piston rod 12, and the other end of the piston rod 12 is connected with the third crank connecting rod 17 and the fourth crank rod 17 respectively. One end of the crank connecting rod 18 is connected, the other end of the third crank connecting rod 17 is connected with one end of the third crank 15 through the third crank shaft 16, the other end of the third crank 15 is connected with the third crank shaft 14, and the other end of the fourth crank connecting rod 18 The fourth crankshaft 21 is connected to one end of the fourth crank 19, and the other end of the fourth crank 19 is connected to the fourth crankshaft 22. The third crankshaft 14 is synchronously fixedly connected to the third gear 13, and the fourth crankshaft 22 is synchronously fixedly connected to the fourth gear 23. , the third crankshaft 14 rotates...

Embodiment 3

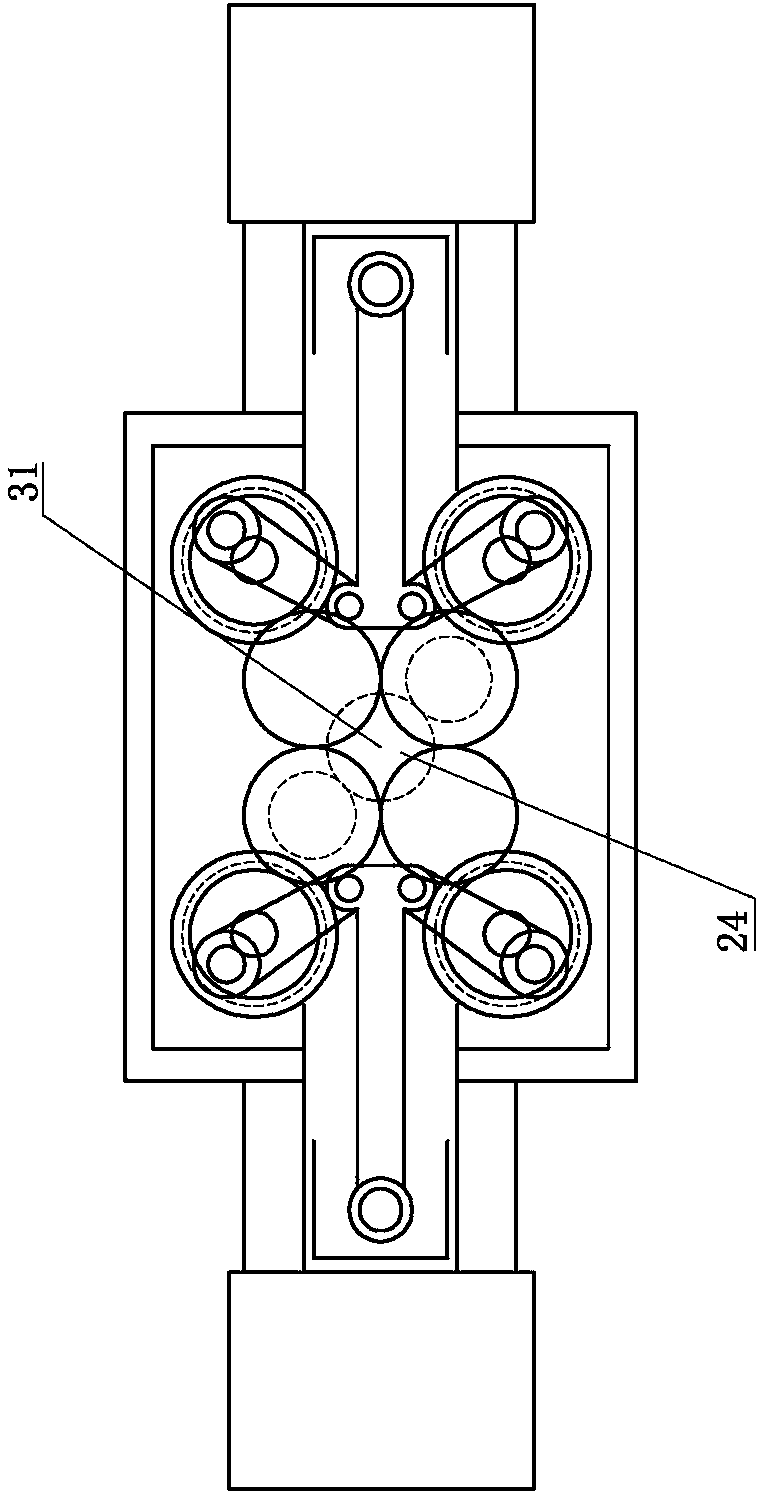

[0076] Embodiment three; as attached image 3 The structure shown is a horizontally opposed scheme of the negative bias anti-pull structure described in the second embodiment. In order to reduce the volume, the directly coupled synchronous third gear 13 and fourth gear 23 are replaced by two intermediary gears meshing , the intermediate gear meshes with the central gear 24 after deceleration, and outputs power through the central output shaft 31.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com