Film-plated glass

A technology of coated glass and glass, applied in the direction of glass/slag layered products, chemical instruments and methods, layered products, etc., can solve the problems of large light pollution, shortened service life of glass, and affect service life, so as to improve acid resistance and Abrasion resistance, increase heat insulation and sound insulation effect, improve the effect of bonding tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

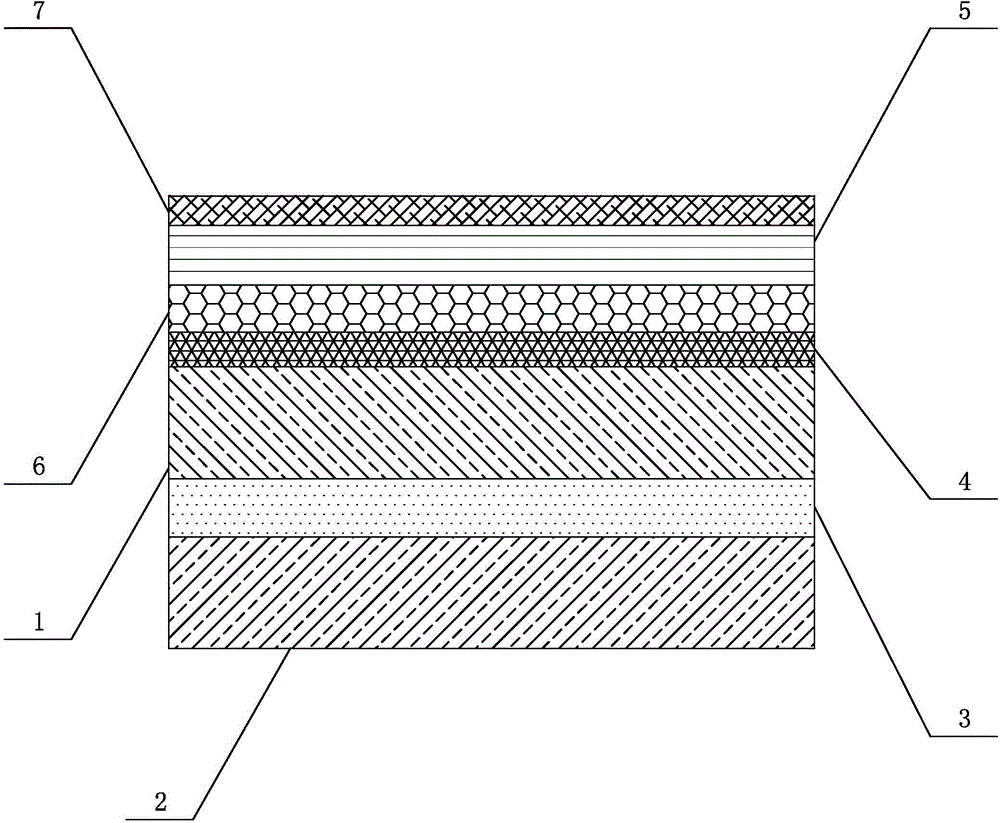

[0019] like figure 1 As shown, a specific embodiment of the present invention is proposed: a coated glass, comprising an outer layer of glass 1, an inner layer of glass 2, and a thermal insulation layer 3 between the two layers of glass, the thermal insulation layer 3 being a silicon oxide mesoporous film Floor.

[0020] The outer surface of the outer glass 1 is sequentially provided with a single-layer silicon-based nano-film layer 4 and a low-emissivity film layer 5 from the inside to the outside, and the outer surface of the low-emissivity film layer 5 is covered with a graphite coating protective layer 7; this embodiment For example, the thickness of the single-layer silicon-based nano-film layer 4 is preferably set to be 40-60 nm, which ensures that the sunlight can be better controlled and the single-layer silicon-based nano-film layer 4 is tightly combined with the outer glass 1 .

[0021] A film layer 6 is arranged between the single-layer silicon-based nano-film laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com