Preparation method for high-stable-activity titanium silicalite molecular sieve catalyst

A titanium-silicon molecular sieve and catalyst technology, which can be used in molecular sieve catalysts, preparation of organic compounds, molecular sieves and alkali exchange compounds, etc., can solve problems such as the decline of reaction performance, and achieve the effect of improving lifespan, not easy to run off, and improving acid and alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

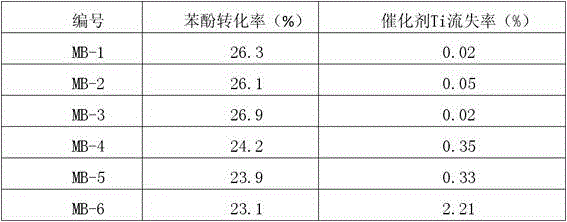

Examples

Embodiment 1

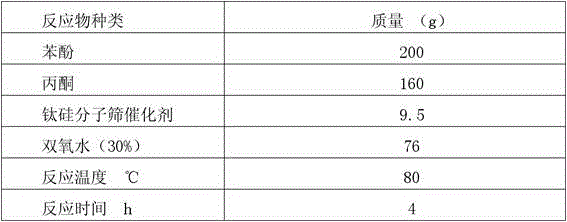

[0025] Embodiment 1 A preparation method of a highly stable and active titanium-silicon molecular sieve catalyst comprises the following steps:

[0026] (1) Prepare materials according to the following ratio

[0027] Component (mass unit) kg

[0028] Tetraethyl orthosilicate 45

[0029] Tetrapropyl ammonium hydroxide 15

[0030] Polyoxyethylene ether-polypropylene ether-polyoxyethylene ether (P123) 0.05

[0031] Polyether modified fluorinated polydimethylsiloxane 0.003

[0032] Tetrabutyl titanate 2

[0033] Anhydrous isopropanol 10

[0034] 8-fluoro-4-hydroxy-2-trifluoromethylquinoline 0.003

[0035] distilled water 100

[0036] (2) Preparation of colloid

[0037] In a 500L stainless steel reactor, modify tetraethyl orthosilicate, tetrapropylene grade ammonium hydroxide, polyoxyethylene ether-polypropylene ether-polyoxyethylene ether (P123), and polyether according to the ratio in step (1). Mix fluorine-containing polydimethylsiloxane and distilled water evenly and c...

Embodiment 2

[0042] Embodiment 2 A preparation method of a highly stable and active titanium-silicon molecular sieve catalyst comprises the following steps:

[0043] (1) Prepare materials according to the following ratio

[0044] Component (mass unit) kg

[0045] Tetraethyl orthosilicate 30

[0046] Tetrapropyl ammonium hydroxide 10

[0047] Polyoxyethylene ether-polypropylene ether-polyoxyethylene ether (P123) 0.01

[0048] Polyether modified fluorinated polydimethylsiloxane 0.001

[0049] Tetrabutyl titanate 1

[0050] Anhydrous isopropanol 5

[0051] 8-fluoro-4-hydroxy-2-trifluoromethylquinoline 0.001

[0052] distilled water 100

[0053] (2) Preparation of colloid

[0054]In a 500L stainless steel reactor, modify tetraethyl orthosilicate, tetrapropylene ammonium hydroxide, polyoxyethylene ether-polypropylene ether-polyoxyethylene ether (P123), and polyether according to the ratio in step (1). Fluorine-containing polydimethylsiloxane and distilled water are mixed evenly for hyd...

Embodiment 3

[0059] Embodiment 3 A preparation method of a highly stable and active titanium-silicon molecular sieve catalyst comprises the following steps:

[0060] (1) Prepare materials according to the following ratio

[0061] Component: (mass unit) kg

[0062] Tetraethyl orthosilicate 60

[0063] Tetrapropyl ammonium hydroxide 20

[0064] Polyoxyethylene ether-polypropylene ether-polyoxyethylene ether (P123) 0.1

[0065] Polyether modified fluorinated polydimethylsiloxane 0.005

[0066] Tetrabutyl titanate 4

[0067] Anhydrous isopropanol 15

[0068] 8-fluoro-4-hydroxy-2-trifluoromethylquinoline 0.005

[0069] distilled water 100

[0070] (2) Preparation of colloid

[0071] In a 500L stainless steel reactor, modify tetraethyl orthosilicate, tetrapropylene ammonium hydroxide, polyoxyethylene ether-polypropylene ether-polyoxyethylene ether (P123), and polyether according to the ratio in step (1). Mix fluorine-containing polydimethylsiloxane and distilled water evenly for hydroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com