Method for purifying smelting waste acid

A dirty acid and zinc smelting technology, applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems of high operating cost, complex process, and many equipment, and achieve the effects of small equipment footprint, simple process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

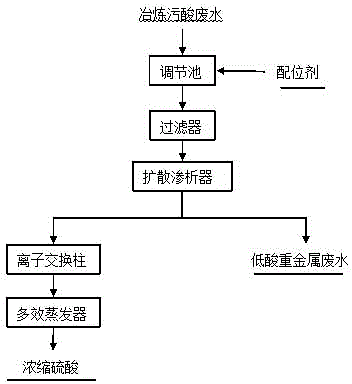

Image

Examples

Embodiment 1

[0028] Embodiment 1: configuration sulfuric acid mass fraction is 5.0%, zinc ion concentration 90mg / L, lead ion concentration 10mg / L, antimony ion concentration 15mg / L, chloride ion concentration 9000mg / L, the mock dirty acid of fluoride ion concentration 3000mg / L solution. In the simulated sewage acid, the molar ratio is Al: (F - +Cl - ) = 1:3 by adding anhydrous aluminum sulfate, stirring to dissolve completely, and then filtering to remove insoluble impurities. Inject 1L of simulated dirty acid and tap water into the head tank respectively. The anion exchange membrane used in the diffusion dialysis device is the DF120 anion exchange membrane produced by a certain company, with a membrane area of 1.93m 2 . The inlet flow rate of dirty acid is 0.4L / h, and the flow rate of receiving liquid is 0.4L / h. After dynamic dialysis, the acid concentration in the regenerated acid was 1.18mol / L, the acid recovery rate was 93%, and the heavy metal (Pb, Zn, Sb) rejection rates were ...

Embodiment 2

[0029] Embodiment 2: the polluted acid used in the experiment is the polluted acid produced in the acid production system of the zinc concentrate fluidized furnace roasting flue gas of a certain smelter, the acid mass fraction (in sulfuric acid) 4.6%, the zinc ion concentration 78.4mg / L, the lead ion concentration 1.89mg / L, arsenic concentration 2.04mg / L, cadmium concentration 0.46mg / L, chloride ion concentration 9126.4mg / L, fluoride ion concentration 3152.3mg / L. Measure 1L of dirty acid and put it in a beaker, the molar ratio is Al: (F - +Cl -) = 1:2 ratio of adding anhydrous aluminum sulfate, stirring with a glass rod until completely dissolved. Sludge acid is removed by vacuum filtration device to remove solid particles. Inject 1L of dirty acid and tap water into the head tank respectively. The diffusion dialysis device uses DF120 anion exchange membrane with a membrane area of 1.93m 2 . The inlet flow rate of dirty acid is 0.9L / h, and the flow rate of receiving liqu...

Embodiment 3

[0030] Embodiment 3: the polluted acid used in the experiment is the polluted acid produced in a lead smelting plant utilizing the lead concentrate sintering process to produce flue gas acid production system, acid mass fraction (in sulfuric acid) 5.3%, zinc ion concentration 70.1mg / L, The lead ion concentration is 30.13mg / L, the arsenic concentration is 2.17mg / L, the cadmium concentration is 0.51mg / L, the chloride ion concentration is 10126.4mg / L, and the fluoride ion concentration is 2983.3mg / L. Measure 1L of dirty acid and place it in a beaker, the molar ratio is Fe: (F - +Cl - ) = 1:3 by adding anhydrous ferric sulfate, stirring with a glass rod until completely dissolved. Sludge acid is removed by vacuum filtration device to remove solid particles. Then inject 1L of dirty acid and tap water into the two elevated tanks respectively. The anion exchange membrane used in the diffusion dialysis device is the DF120 anion exchange membrane produced by a certain company, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com