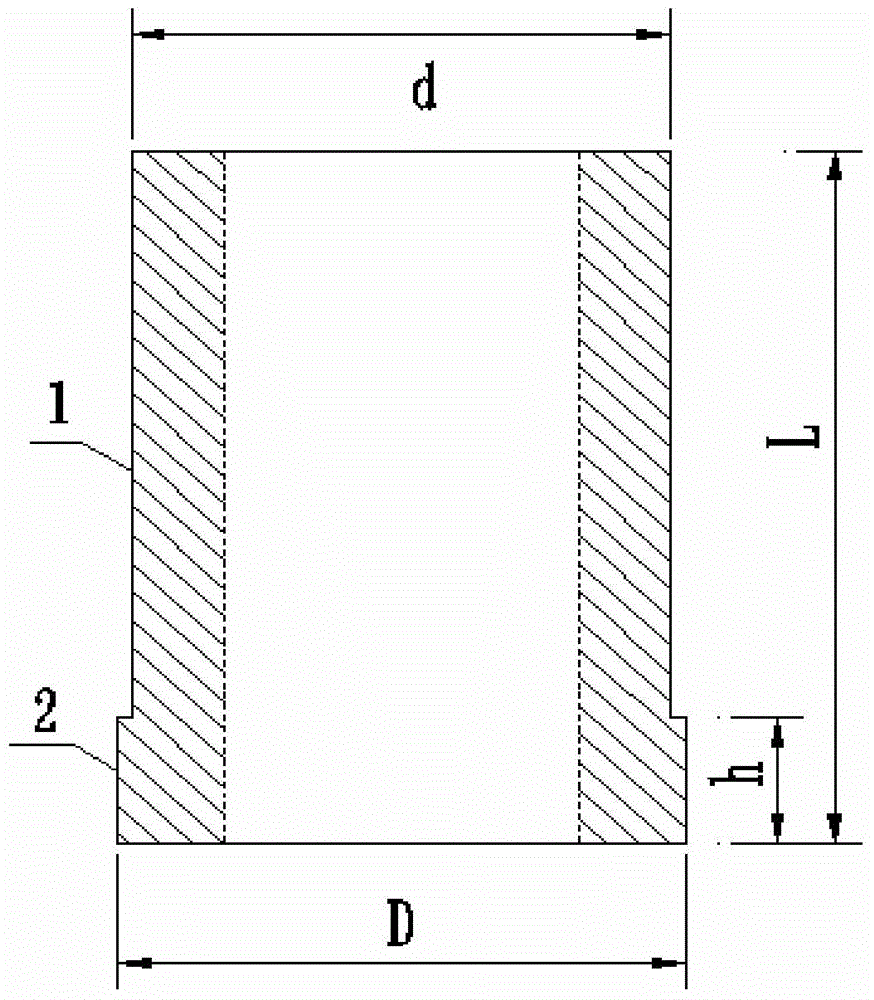

Method for making diamond string beads

A diamond bead and diamond technology, which is applied in the field of diamond bead preparation, can solve problems such as high requirements, loss of liquid phase materials, and easy-to-damage equipment, and achieve the effects of meeting wear resistance requirements, reducing comprehensive energy consumption, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh Fe-based submicron alloy powder (average particle size of 2 μm), CuSn alloy powder (average particle size of 30 μm) and W powder (average particle size of 5.5 μm) composed of Fe45Co17Cu38 in a weight ratio of 17:1:2 ) a total of 1kg, mixed evenly to obtain a mixed powder; take 5.0g of WS-120 granulation agent, dissolve it in 20g of absolute ethanol to make a solution, slowly drop it into the above mixed powder, and place it in a stirring granulator Mixing in the medium, so that the metal powder is aggregated to achieve the purpose of granulation, and the granular material is obtained; wherein, the Fe-based submicron alloy powder composed of Fe45Co17Cu38 is prepared according to the following method:

[0035] According to the molar ratio of the substance, n(Fe 2+ ):n(Co 2+ ):n(Cu 2+ )=45:17:38 ratio configuration concentration is 1.5mol / L FeCl 2 、CoCl 2 , CuCl 2 Mix 50L of solution and 50L of oxalic acid solution with a concentration of 1.8mol / L (the temper...

Embodiment 2

[0042] Repeat Example 1, the difference is:

[0043] ① The composition of Fe-based submicron alloy powder is Fe43Co17Cu40, and its average particle size is 3 μm; the auxiliary materials are WC powder, Zn powder and Al powder, and their average particle size is 8 μm. The Fe-based submicron alloy powder, WC powder, Zn powder The weight ratio to Al powder is 87:8:3:2.

[0044] 2. Take copper-plated coated diamond (wherein particle size 40 / 45 accounts for 50%, particle size 45 / 50 accounts for 40%, and particle size 50 / 60 accounts for 10%) by weighing the concentration of 1.6 carats per cubic centimeter and add it in the granular material; The relative density of the carcass ring obtained after cold pressing and free sintering of the carcass material is ≥ 97%, and the Rockwell hardness ≥ 90HRB. The rectangular parallelepiped carcass standard sample (30×12× 6) Three-point bending strength ≥ 1000MPa;

[0045] ③Free sintering temperature and time: sintering at 650°C for 40 minutes, ...

Embodiment 3

[0047] Repeat Example 1, the difference is:

[0048] ①The composition of Fe-based submicron alloy powder is Fe44Co19Cu37, (average particle size is 3μm;

[0049] 2. Weigh copper-plated coated diamond (wherein particle size 40 / 45 accounts for 35%, particle size 45 / 50 accounts for 45%, and particle size 50 / 60 accounts for 20%) by weighing the concentration of 1.5 carats per cubic centimeter, and add it to the granular material to obtain The relative density of the carcass ring obtained after cold pressing and free sintering of the carcass material is ≥98%, and the Rockwell hardness is ≥90HRB. The rectangular parallelepiped carcass standard sample (30×12×6 ) three-point bending strength ≥ 1150MPa;

[0050] ③Free sintering temperature and time: sintering at 550°C temperature zone for 50 minutes, sintering at 650°C temperature zone for 40 minutes, sintering at 750°C temperature zone for 30 minutes, sintering at 850°C temperature zone for 50 minutes, and sintering at 750°C for 110 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com