Cobalt-based catalyst and preparation method and application thereof

A cobalt-based catalyst and catalyst technology, applied in the field of nanocomposite, can solve the problems of limited use of catalyst, low complete conversion temperature, high preparation price, etc., and achieve the effects of good industrial application prospects, excellent combustion activity, and simple synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

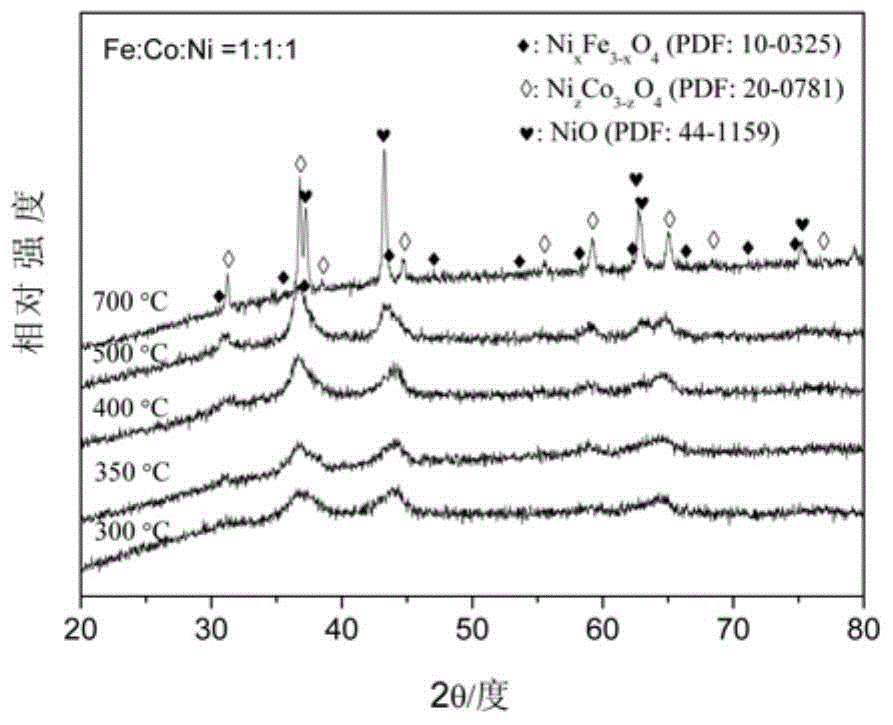

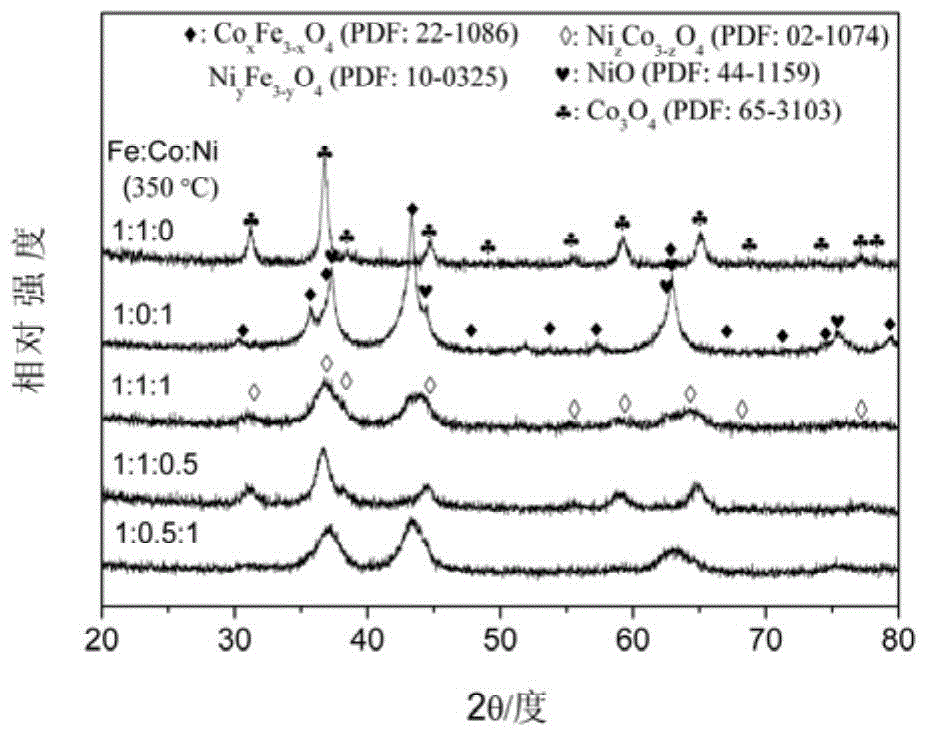

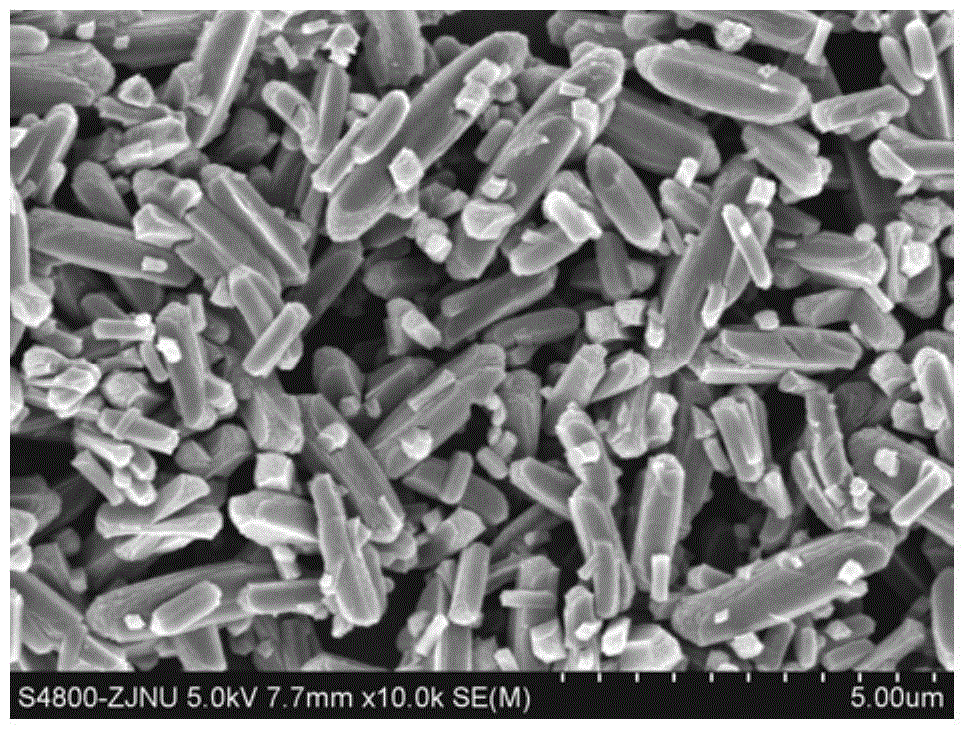

[0044]Mix 0.20 mole of glucose, 0.050 mole of metal salts of iron, cobalt and nickel [iron nitrate: cobalt nitrate: nickel nitrate molar ratio is 1:1:1, the ratio of glucose to metal salt is 4:1] and 100 Add one milliliter of deionized water into a 250-milliliter beaker, stir and react at 60°C, and concentrate and crystallize after a yellow-green precipitate appears. Finally washed, filtered, and dried at 80 °C for 6 hours to obtain a yellow-green precursor. Subsequently, the precursor was calcined at 300° C. for 3 hours in an air atmosphere to obtain a catalyst, which was designated as FeCoNi-300.

Embodiment 2

[0046] The steps are the same as in Example 1, but the firing temperature is 350°C. The catalyst is noted as FeCoNi-350.

Embodiment 3

[0048] Same step as Example 1, but the firing temperature is 500°C. The catalyst is noted as FeCoNi-500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com