Novel Ni-Al base all-metal energetic material and preparation method thereof

An all-metal, new technology, applied in the field of new Ni-Al-based all-metal energetic materials and its preparation, can solve the problems of poor production safety and strict preparation conditions, so as to improve mechanical strength, increase reaction heat release, and ensure preparation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] A novel Ni-Al-based all-metal energetic material, comprising the following steps: selecting Al 12 Mg 17 The powder is used as an added component, mixed evenly with Ni and Al powder, and the Al-Ni-based energetic material shell is prepared by cold spraying method; the Al and Ni powders are spherical, the molar ratio of the components is 1:1, and the Al 12 Mg 17 Irregular powder prepared by mechanical disintegration, Al 12 Mg 17 The powder content is 5% (mass fraction); the particle size is 10-30 μm.

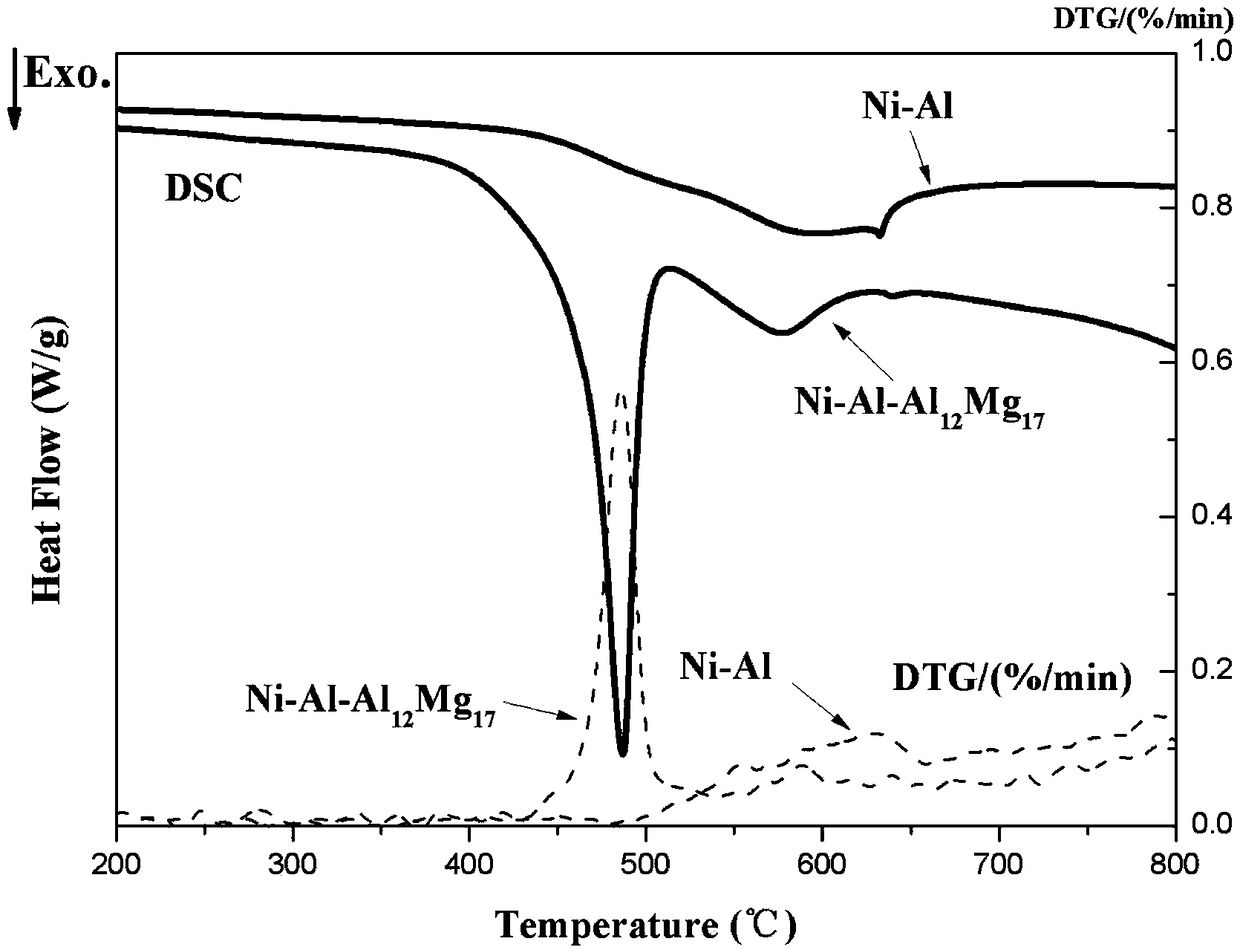

[0019] The microstructure analysis, mechanical performance test and combustion performance analysis of the obtained energetic material shell were carried out; the results are:

[0020] The results of microstructure analysis showed that Al 12 Mg 17 The particles are evenly distributed, the density of the material is about 95%, and the density is about 4.5g / cm 3 . In terms of mechanics, adding Al 12 Mg 17 The dynamic compressive strength of the latter material is ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com