Preparation method of super-hydrophobic polytetrafluoroethylene microporous membrane, membrane prepared by preparation method and application of super-hydrophobic polytetrafluoroethylene microporous membrane

A polytetrafluoroethylene, super-hydrophobic technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problem that the high hydrophobicity of the film cannot be guaranteed for a long time, it is prone to breakage and peeling, and the manufacturing process is complicated. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The method for preparing superhydrophobic polytetrafluoroethylene microporous membrane of the present invention mainly comprises the following three steps: 1) polytetrafluoroethylene resin, extrusion aid, superhydrophobic fluorine-containing material and optional solvent are mixed to form paste; 2) extruding the paste to form a nascent film; 3) heat-treating, stretching and sintering the nascent film to form the superhydrophobic polytetrafluoroethylene microporous film. Those skilled in the art can understand that when the compatibility between the polytetrafluoroethylene resin and the superhydrophobic fluorine-containing material is high, it may not be necessary to use a solvent.

[0051] The polytetrafluoroethylene resin used in the present invention preferably has a crystallinity greater than or equal to 98%, and its number average molecular weight is 3 million to 10 million, preferably 4 million to 9 million, more preferably 5 million to 8 million. The polytetrafluo...

Embodiment

[0076] The polytetrafluoroethylene resin used in the following examples is a dispersed polytetrafluoroethylene resin (FR203A) purchased from Sanaifu Company; the extrusion aid isoparaffin is the Isopar G isoparaffin produced by Exxonmobil Company, with a distillation range of 167- 176°C.

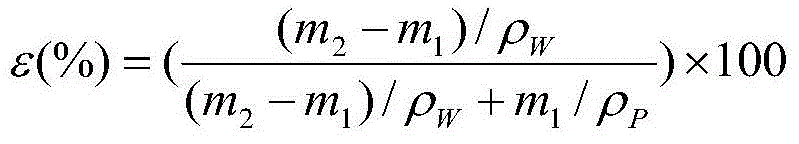

[0077] The porosity of the membrane product of the present invention is measured gravimetrically. Specifically, the membrane material prepared by the present invention is immersed in the ethanol solution for 2 hours, so that the ethanol solution is completely immersed in the membrane pores, so as to clean the membrane pores. After cleaning, put the film material in a vacuum oven, dry it at 105°C for 2 hours, weigh it after drying, and record the dry film mass at this time m 1. The dry film was completely wetted with the ethanol solution, and then it was put into deionized water and soaked in deionized water for 24 hours. In the experiment, the deionized water was replaced every 4 hours, so...

Embodiment 1

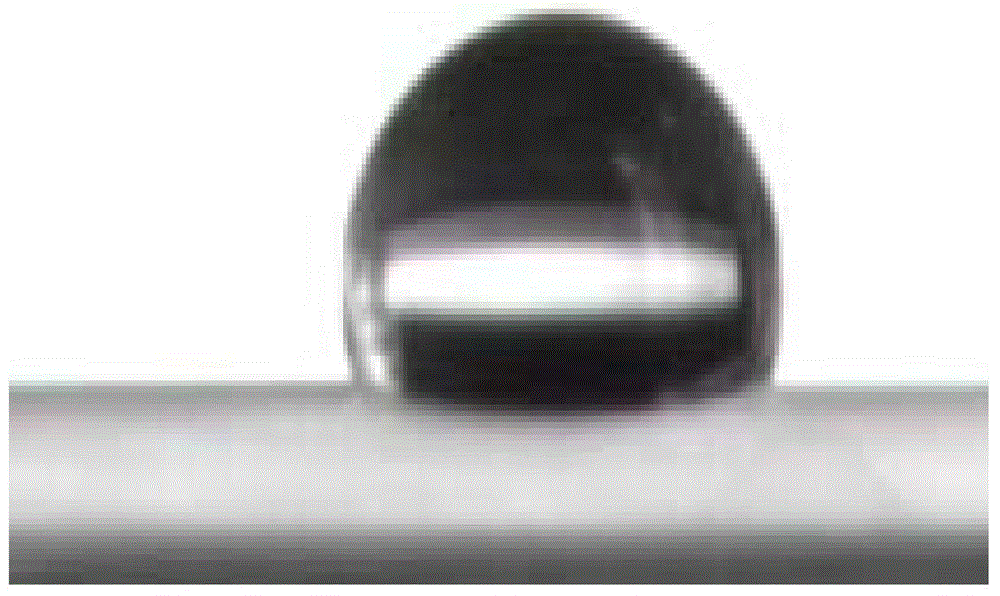

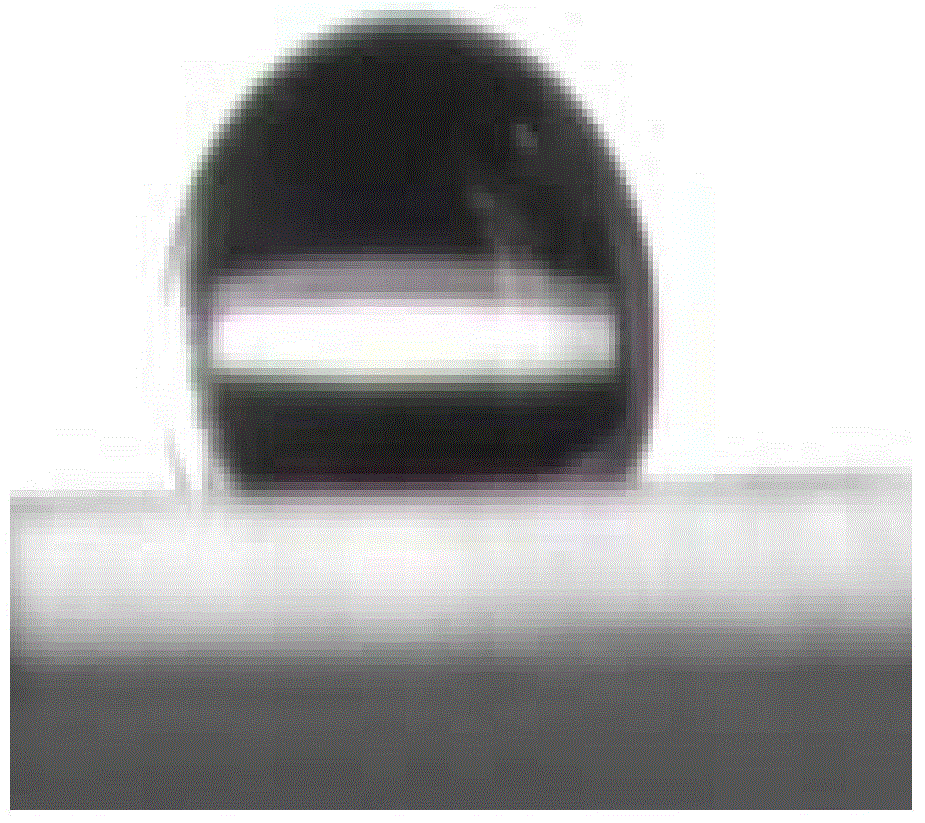

[0081] Example 1: Preparation of hollow fiber-shaped superhydrophobic polytetrafluoroethylene microporous membrane

[0082] 1000 grams of polytetrafluoroethylene resin and 230 grams of extrusion aid aviation kerosene were fully mixed to form a mixed material. In another container, 160 g of perfluorooctylethyl methacrylate (FMA) / methyl methacrylate (MMA) / methacrylic acid (MAA) terpolymer (PMAA-co-PMMA-co -PFMA) (the fluorine atom weight content of the copolymer is 20%, the number average molecular weight is 10000, and the molar ratio of MMA / MAA substance is 2:1; the preparation method refers to the open literature: Hydrophobicity research of water-based fluorine-containing acrylate copolymer , Modern Chemical Industry, Vol. 27 No. 6, p46-49, June 2007) was dissolved in 600 g of solvent (a mixture of ethanol and acetone with a volume ratio of 2:1), and after it was completely dissolved, it was added to the poly The mixed material of tetrafluoroethylene resin and aviation kerose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com