Hydrophilic chromatographic packing as well as preparation method and application thereof

A chromatographic packing and reaction technology, which is applied in the field of analytical chemistry, can solve problems such as limited affinity, and achieve the effect of increasing the number of identifications, improving affinity and loading capacity, and achieving obvious results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

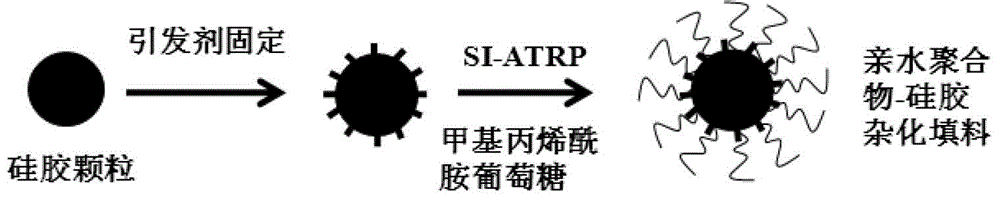

[0059] SI-ATRP method for the preparation of hydrophilic polymer-silica gel hybrid packing flow chart is as follows figure 1 shown.

[0060] 1) Synthesis of 2-glucosaminopropyl methacrylate (GMA-G) monomer: Add 0.2M sulfuric acid to 674.53 μl glycidyl methacrylate (GMA), place it in a water bath at 50°C and heat it for the second step. After the first oxidation reaction for 4 hours, 1.09 g of sodium periodate was added and mixed, and the second oxidation reaction was carried out at room temperature in the dark for 2 hours to obtain oxidized GMA;

[0061] Measure another 20 ml of methanol, gradually add 1.1 g of glucosamine, and stir until dissolved. The obtained oxidized GMA was added dropwise to the continuously stirring methanol solution of glucosamine, stirred at room temperature for schiff base reaction for 4 hours to obtain a yellow transparent solution, and the prepared solution was blown to dryness with nitrogen until it was a paste, and GMA- G monomer, sealed and fil...

Embodiment 2

[0073] Example 2, using the chromatographic filler obtained in Example 1 to enrich glycopeptides

[0074] 1) Take 10 mg of the chromatographic filler prepared in Example 1 and dissolve it in acetonitrile, fill it into a 200ul pipette tip, and precipitate naturally to prepare a solid phase extraction column;

[0075] 2) An appropriate amount of bovine fetuin (Sigma, CAS: 9014-81-7) was weighed and dissolved in 50 mM ammonium bicarbonate solution with a final concentration of 1 μg / μl. Add mercaptoethanol at a final concentration of 10 mM, reduce in a water bath at 56°C for 1 hour, then add IAA and place in the dark for 1 hour to denature the glycoprotein. Take the denatured glycoprotein and add trypsin at a mass ratio of 1:50 (trypsin: protein), place it in a 37°C water bath and incubate for 12 hours, then add 0.1% TFA to inactivate the trypsin to obtain an enzymatic hydrolysis product.

[0076] The obtained enzymatic hydrolysis product was divided into two parts, one part was ...

Embodiment 3

[0081] Embodiment 3, utilize the chromatographic filler obtained in embodiment 1 to carry out the enrichment of oligosaccharide

[0082] 1) Take 10 mg of the chromatographic filler prepared in Example 1 and dissolve it in acetonitrile, fill it into a 200ul pipette tip, and precipitate naturally to prepare a solid phase extraction column;

[0083] 2) Take 50 μg of chicken ovalbumin (Sigma Company, CAS: 9006-59-1) and dissolve it in 50 mM ammonium bicarbonate solution with a final concentration of 1 μg / μl. After thermal denaturation in a boiling water bath for 10 minutes, cool to room temperature, add an appropriate amount of denatured protein to PNGase F (the mass ratio of enzyme and protein is 1:20), and incubate in a 37°C water bath for 16 hours. The enzymatic hydrolyzate was lyophilized and dissolved in acetonitrile / water / formic acid (80:20:0.1, v / v) with a final concentration of 1 μg / μl. Rinse the solid-phase extraction column with 30 μl acetonitrile / water / formic acid (10:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com