Patch type white LED light curing and packaging device and application thereof

A packaging device and patch-type technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that the cured products do not have the ability to resist sunlight UVA damage, cannot add anti-yellowing agents, and white LED light decay. Achieve the effect of improving the consistency of optical performance, reducing light attenuation, and irradiating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

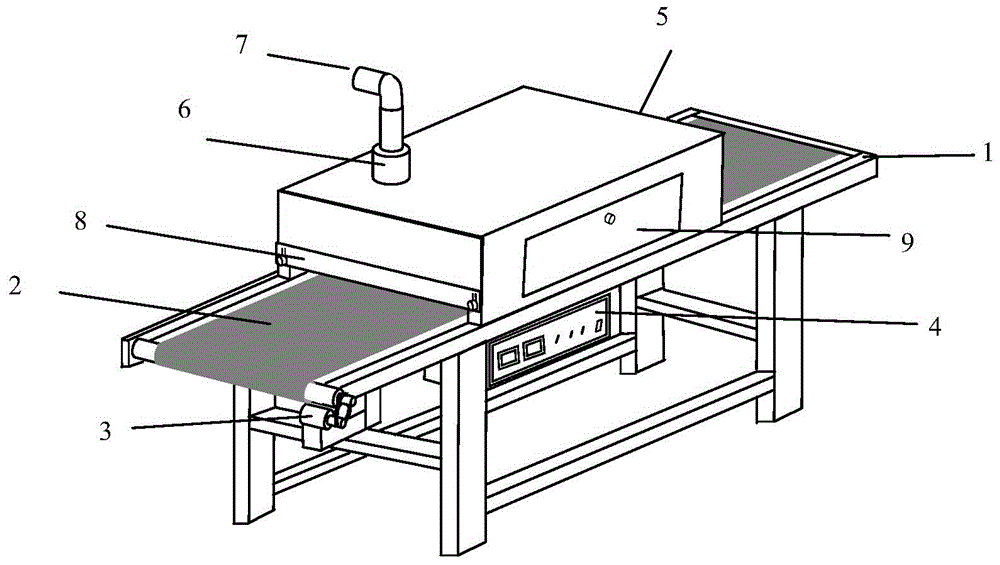

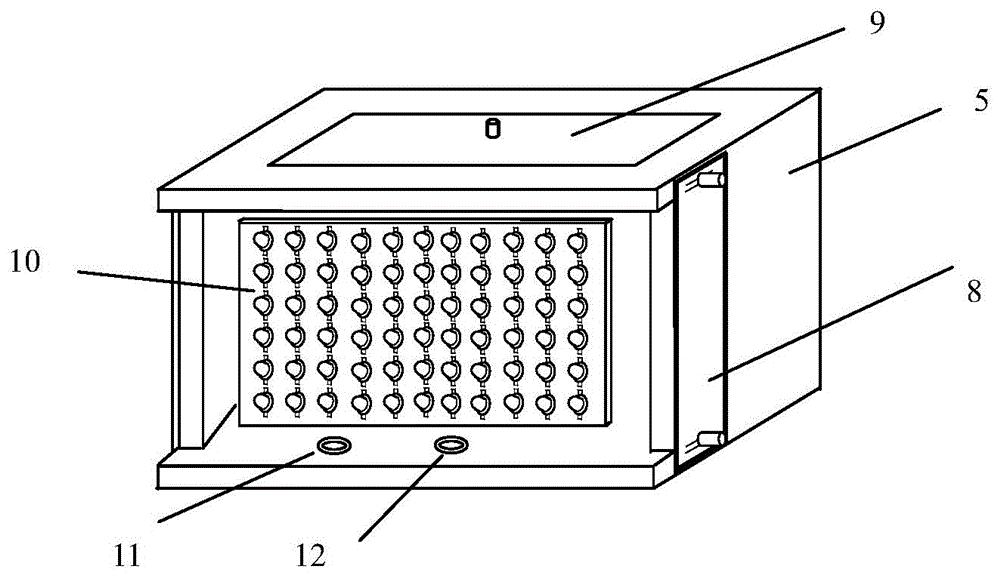

[0031] Such as figure 1 As shown, the machine 1 is made of stainless steel, and the conveyor belt 2 of the metal mesh chain is driven by the speed-regulating motor 3 and controlled by the single-chip microcomputer system in the electric control box 4. The speed of the conveyor belt 2 can be changed to determine the curing time, and the conveyor belt can also be set 2. Work in the intermittent traveling mode, and determine the intermittent time as the curing time. The middle part of the conveyor belt 2 is fixed with a UV-LED light source box 5, on which a fan 6 and an exhaust pipe 7 are housed, and the fan 6 can regulate the temperature in the light source box 5 by adjusting the speed of the single-chip microcomputer system. A visor 8 that can move up and down is respectively installed on both sides of the light source box. A light source maintenance port 9 for easy maintenance is left on the side of the light source box 5 . exist figure 2 Among them, a high-power deep ultr...

Embodiment 2

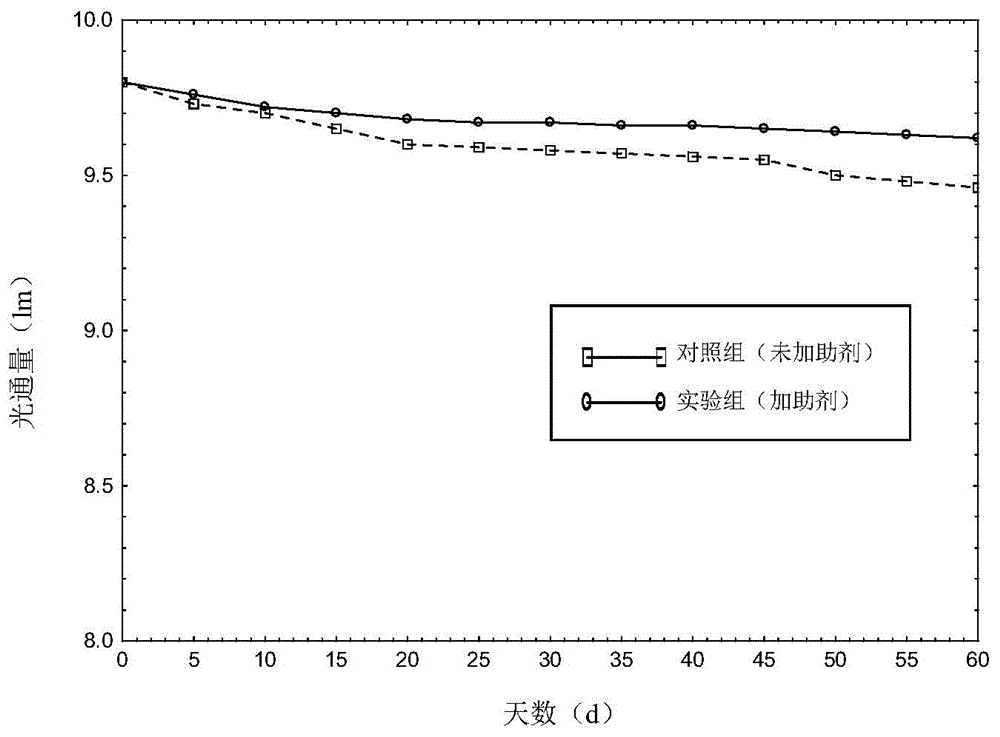

[0033] In the E-51 type epoxy resin of 100 mass parts, add 100 mass parts hexahydrophthalic anhydride curing agent, 4 mass parts polyether toughening agent, 4 mass parts [10-(4-biphenyl)- 2-isopropylthioxanthone hexafluorophosphate] cationic photoinitiator (omnicat550 photoinitiator, absorption wavelength 280nm), 2 parts by mass of antioxidant and ultraviolet absorber binary compound anti-yellowing agent V76- P. 1 part by mass of hindered amine light stabilizer Tinuvin292. Then add 4 parts by mass of YAG yellow fluorescent powder, fully mix, stir and vacuumize to remove air bubbles, and then apply it to the SMD LED cup groove where the blue chip has been fixed and the gold wire is welded, until the cup groove is completely covered, and the 10 as the experimental group. In the cured glue of the control group, the anti-yellowing agent and light stabilizer were removed, and the rest of the process and formula were the same, and 10 were produced. The two groups of coated LEDs we...

Embodiment 3

[0035] The light-curing adhesive formula and process of the device in Example 1 and the experimental group in Example 2 were used. The light intensity is adjusted to 160mW / cm 2 , the temperature is controlled at 120°C. Adjust the speed of the conveyor belt 2 so that the cured SMD LEDs stay in the light source box 5 for 120 seconds, 150 seconds, 180 seconds, 210 seconds, 240 seconds, and 270 seconds respectively, and 10 of the 6 cured samples are made respectively, and cured and packaged The completed LED is placed in the light aging machine and turned on for 60 days. After testing, the light decay curve is as follows: Figure 4 . It can be seen that the curing time of 180 seconds has the smallest light decay, so 180 seconds is the best curing time under the corresponding light intensity and temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com