Steam-liquid-solid three-phase energy accumulator

A three-phase energy storage tank and accumulator technology, applied in the field of energy storage, can solve the problems of imbalance, inability to fully utilize the energy storage potential of the solution, and concentration difference limitation, and achieve the improvement of energy storage density, volume reduction, and simple control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

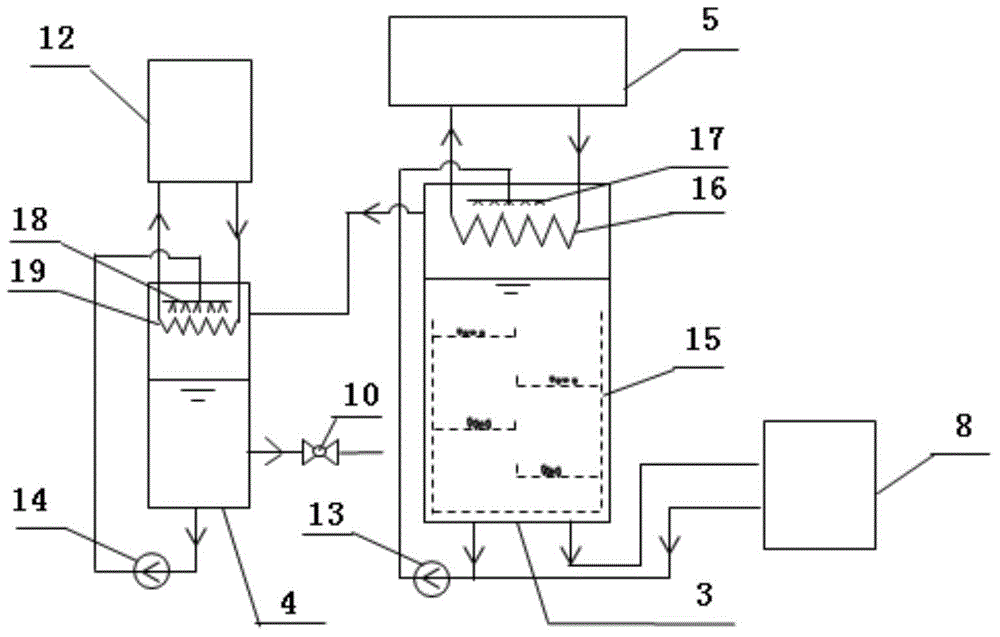

[0016] The patent of the present invention will be further described below in conjunction with the drawings.

[0017] See figure 1 with figure 2 , The three-phase accumulator 1 includes a three-phase accumulator tank 3 and a liquid refrigerant accumulator tank 4. When accumulating energy, the three-phase accumulator 1 stores the excess heat of the heat source 5 in the three-phase accumulator 1. The heat source 5 directly provides heat to the three-phase accumulator tank 3, using the porous surface in the three-phase accumulator tank 3. The tube heat exchanger 16 heats the energy storage medium and relies on the solution spray pump 13 to pressurize and the solution nozzle 17 to spray during the heating process. The solution is heated and concentrated until crystals are produced, and the crystals are distributed in the crystal distributor 15 The refrigerant vapor generated by heating enters the liquid refrigerant storage tank 4 (for example, when the lithium bromide-water solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com