Modified PVDF base material for solar battery backplane and preparation method thereof

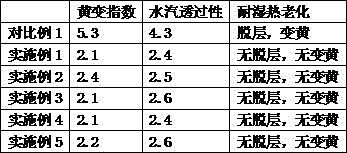

A technology for solar cells and backplanes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low resistance, achieve the effects of reduced affinity, improved heat and humidity resistance, and less delamination and yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A modified PVDF base material for a solar battery back sheet, comprising the following components in parts by weight: 75 parts of tetrabutylphosphine chloride, 60 parts of PVDF, 70 parts of benzyltributylammonium chloride, and 40 parts of polyvinyl butyral 85 parts, polytetrafluoroethylene 85 parts, chloromethyl styrene 53 parts, sodium tartrate 55 parts, polyphosphate 60 parts, phthalates 60 parts, aliphatic amines 35 parts.

[0029] Polyphosphate is a mixture of sodium pyrophosphate, trisodium phosphate and sodium hexametaphosphate in a mass ratio of 1:3:1.

[0030] Phthalates are a mixture of dicyclohexyl phthalate, butyl benzyl phthalate, and diisobutyl phthalate in a mass ratio of 1:2:1.

[0031] Aliphatic amines are mixtures of diaminocyclohexane, methylenebicyclohexaneamine and tetraethylenepentamine in a mass ratio of 2:1:1.

[0032] The preparation method of the modified PVDF base material for the above-mentioned solar battery back plate comprises the followin...

Embodiment 2

[0039] A modified PVDF base material for a solar battery back sheet, comprising the following components in parts by weight: 60 parts of tetrabutylphosphine chloride, 30 parts of PVDF, 30 parts of benzyl tributylammonium chloride, 20 parts of polyvinyl butyral 70 parts, polytetrafluoroethylene 70 parts, chloromethyl styrene 40 parts, sodium tartrate 40 parts, polyphosphate 30 parts, phthalates 40 parts, aliphatic amines 20 parts.

[0040] Polyphosphate is a mixture of sodium pyrophosphate, trisodium phosphate and tetrasodium phosphate in a mass ratio of 1:1:1.

[0041] The phthalates are butyl benzyl phthalate.

[0042] The aliphatic amine is triethylenetetramine.

[0043] The preparation method of the modified PVDF base material for the above-mentioned solar battery back plate comprises the following steps:

[0044] (1) Tetrabutylphosphine chloride, PVDF, benzyltributylammonium chloride, polyvinyl butyral, polytetrafluoroethylene, chloromethylstyrene, phthalates, aliphatic ...

Embodiment 3

[0049]A modified PVDF base material for a solar battery back sheet, comprising the following components in parts by weight: 90 parts of tetrabutylphosphine chloride, 100 parts of PVDF, 100 parts of benzyl tributylammonium chloride, 60 parts of polyvinyl butyral 100 parts of polytetrafluoroethylene, 60 parts of chloromethyl styrene, 40 parts of sodium tartrate, 30 parts of polyphosphate, 40 parts of phthalates, and 20 parts of aliphatic amines.

[0050] Polyphosphate is a mixture of sodium pyrophosphate, tetrasodium phosphate and sodium hexametaphosphate with a mass ratio of 5:2:1.

[0051] Phthalates are a mixture of dicyclohexyl phthalate and diisobutyl phthalate in a mass ratio of 1:3.

[0052] The aliphatic amines are mixtures of diaminocyclohexane, diethylenetriamine and triethylenetetramine in a mass ratio of 1:5:1.

[0053] The preparation method of the modified PVDF base material for the above-mentioned solar battery back plate comprises the following steps:

[0054] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com