Method for controlling growth of carbon nanotube bundle in horizontal direction of substrate

A carbon nanotube bundle, horizontal direction technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve problems such as inability to meet nanoelectronic devices, complex template processing, damage to carbon nanotube structures, etc., and achieve precise and controllable positions. , the process is simple, the effect of easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

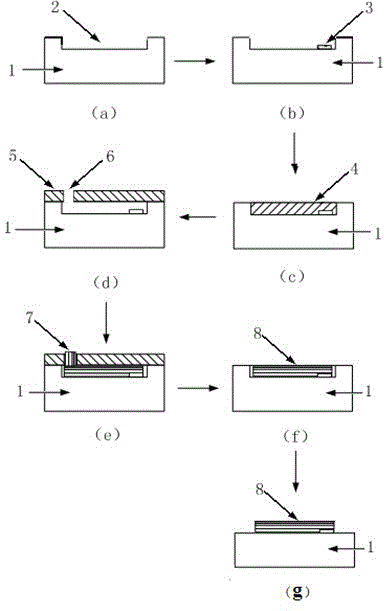

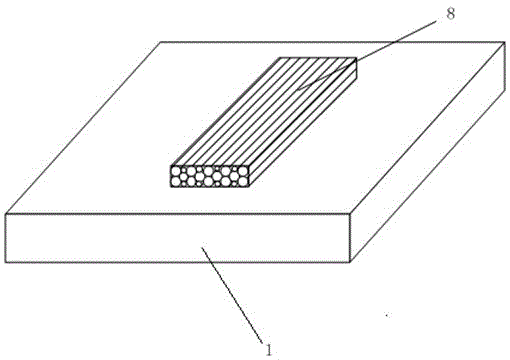

[0043] (1) Prepare a piece of silicon wafer 1, use conventional semiconductor cleaning process to clean, dry, use photolithography process and ion reactive etching process to process a 10 micron long and 2 wide carbon nanotube film on the surface of the silicon wafer Micron, horizontal micro-nano channel 2 with a depth of 2 microns;

[0044] (2) Spin-coat a layer of AZ4620 photoresist on the surface of the silicon wafer 1 with a coater, with a thickness of 3 microns, expose and develop the catalytic film deposition window, and deposit 6 nm-thick photoresist on the surface of the silicon wafer sequentially using an electron beam evaporation process. The Al2O3 layer and the 1 nanometer thick Co layer form the catalytic film 3, the photoresist is removed, and the catalytic film on the photoresist is removed together thereupon, leaving the patterned catalytic film 3 in the micro-nano channel 2, the catalysis The film size is 2 microns wide and 2.2 microns long;

[0045] (3) Spin-...

Embodiment 2

[0050] (1) Prepare a piece of quartz plate 1, use conventional semiconductor cleaning process to clean, dry, use photolithography process and ion reaction etching process to process 10 microns in length and 2 microns in width at the position where carbon nanotube bundles need to be grown on the surface of the quartz plate , a horizontal micro-nano channel 2 with a depth of 2 microns;

[0051] (2) Spin-coat a layer of AZ4620 photoresist on the surface of the quartz plate 1 with a homogenizer, with a thickness of 3 microns, expose and develop the catalytic film deposition window, and deposit 10 nanometers of photoresist on the surface of the quartz plate sequentially using an electron beam evaporation process. The Al2O3 layer and the 2 nanometer thick Fe layer form the catalytic film 3, remove the photoresist, and the catalytic film on the photoresist is removed together thereupon, leaving the patterned catalytic film 3 in the micro-nano channel 2, catalyzed The membrane size is...

Embodiment 3

[0057] (1) Prepare a piece of aluminum oxide sheet 1, clean it with conventional semiconductor cleaning process, dry it, and use photolithography process and ion reaction etching process to process a 10 micron long and 2 wide carbon nanotube bundle on the aluminum oxide surface. Micron, horizontal micro-nano channel 2 with a depth of 2 microns;

[0058] (2) Spin-coat a layer of AZ4620 photoresist on the surface of alumina sheet 1 with a coater, with a thickness of 3 microns, expose the catalytic film deposition window by exposure and development, and deposit 12 nanometers on the surface of alumina sheet sequentially using electron beam evaporation process A thick Al2O3 layer and a 3nm-thick Ni layer form the catalytic film 3, the photoresist is removed, and the catalytic film on the photoresist is removed together, leaving the patterned catalytic film 3 in the micro-nano channel 2 , the size of the catalytic membrane is 2.4 microns in length and 2 microns in width;

[0059] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com