A fully automatic computerized jacquard machine color changing mechanism

A computerized jacquard machine, fully automatic technology, applied to the production of fleece products, etc., can solve the problems of jacquard machine head failure rate increase, color change is not in place, needle bar rack burden, etc., to avoid manual shutdown Color change, improve the efficiency of color change, the effect of simple and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

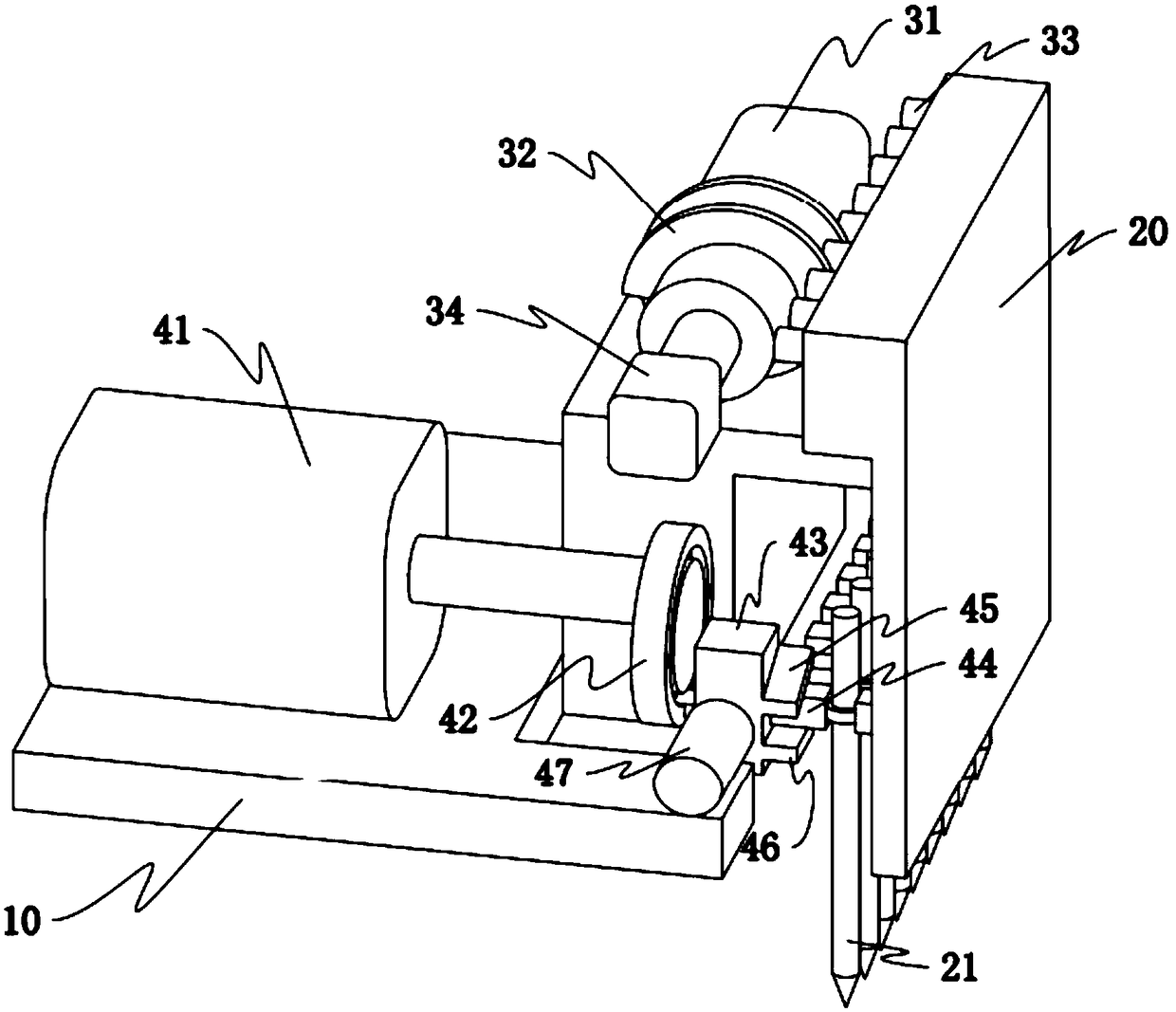

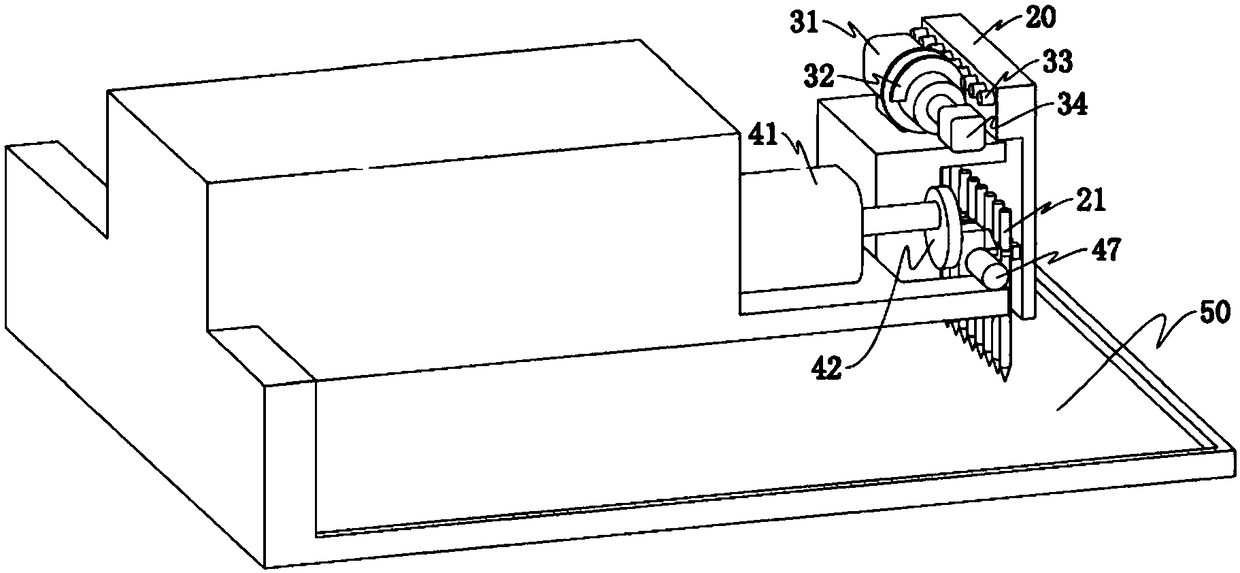

[0020] exist figure 1 Shown is a mechanism diagram of an embodiment of a fully automatic computerized jacquard color-changing mechanism of the present invention, the color-changing mechanism includes a base 10, a needle bar frame 20 fixed on the base 10 and several uniform The needle bar 21 fixed on the needle bar frame, the upper side of the needle bar frame 20 is provided with a moving mechanism that controls the needle bar frame 20 to move stepwise along the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com