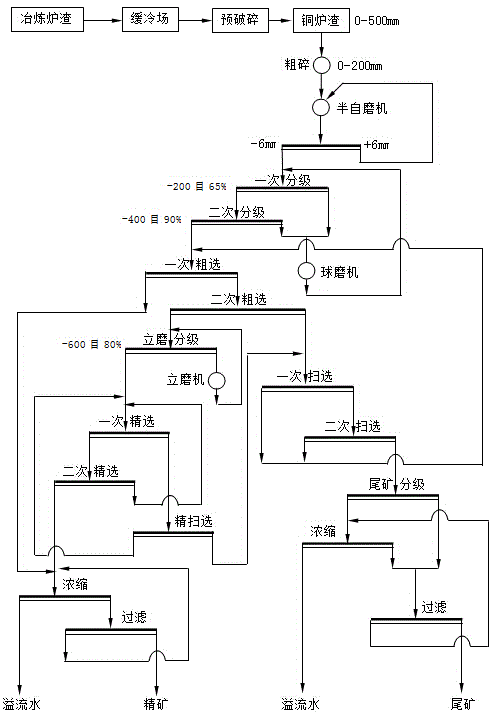

Copper furnace slag mineral processing process

A slag and process technology, applied in the field of copper slag beneficiation technology, can solve the problems of poor effect of fine-grained copper minerals, low comprehensive recovery rate of copper slag beneficiation, large differences in slag crystal structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] The copper furnace slag package transported from smelting has a copper metal content of 1.5%, and it is implemented according to the following steps:

[0043] After concentrated and natural slow cooling for 12 hours, spray cooling (water pressure is 0.3Mpa), after spraying for 60 hours, dump it in the slag yard. The stone crusher crushes the bulk slag in the slag yard, so that the particle size of the material is below 500mm, and the rod feeder and belt conveyor are sent to the jaw crusher for crushing, and the product particle size is below 200mm. The crushed products are sent to semi-autogenous mill for grinding by belt conveyor and iron plate feeder. After the ore discharge of the semi-autogenous mill is screened by the vibrating screen, the overflow with a particle size below 6mm enters a classification operation, and then returns to the semi-autogenous grinding operation to form a closed circuit. The overflow after the primary classification operation (the finenes...

example 2

[0051] The copper slag package transported from smelting has a copper metal content of 2.1%, and it is implemented according to the following steps:

[0052] After concentrated and natural slow cooling for 12 hours, spray cooling (water pressure is 0.3Mpa), after spraying for 60 hours, dump it in the slag yard. The stone crusher crushes the bulk slag in the slag yard, so that the particle size of the material is below 500mm, and the rod feeder and belt conveyor are sent to the jaw crusher for crushing, and the product particle size is below 200mm. The crushed products are sent to semi-autogenous mill for grinding by belt conveyor and iron plate feeder. After the ore discharge of the semi-autogenous mill is screened by the vibrating screen, the overflow with a particle size below 6mm enters a classification operation, and then returns to the semi-autogenous grinding operation to form a closed circuit. The overflow after the primary classification operation (the fineness is -20...

example 3

[0060] The copper slag package transported from smelting has a copper metal content of 3.15%, and it is implemented according to the following steps:

[0061]After concentrated and natural slow cooling for 12 hours, spray cooling (water pressure is 0.3Mpa), after spraying for 60 hours, dump it in the slag yard. The stone crusher crushes the bulk slag in the slag yard, so that the particle size of the material is below 500mm, and the rod feeder and belt conveyor are sent to the jaw crusher for crushing, and the product particle size is below 200mm. The crushed products are sent to semi-autogenous mill for grinding by belt conveyor and iron plate feeder. After the ore discharge of the semi-autogenous mill is screened by the vibrating screen, the overflow with a particle size below 6mm enters a classification operation, and then returns to the semi-autogenous grinding operation to form a closed circuit. The overflow after the primary classification operation (the fineness is -20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com