Acid-corrosion-resistant X70 pipeline steel plate and manufacturing method thereof

A technology of acid resistance and steel plate, which is applied in the manufacture of steel plates and the field of steel plates for acid corrosion resistance X70MS pipelines. It can solve the problems of lack of SSCC resistance inspection items, low temperature toughness, formability weldability, unfavorable ductility, and large oxygen blowing volume. Achieve excellent HIC and SSCC acid corrosion resistance, good HIC and SSCC resistance, and strong performance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

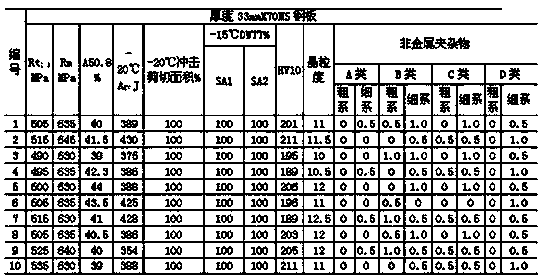

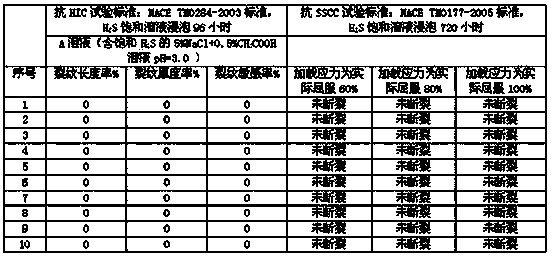

Embodiment 1

[0035] The overall process flow of 33mm X70MS wide and thick steel plate is: high-quality molten iron - KR molten iron pretreatment - 210 tons of top and bottom double blowing converter smelting - CAS station argon blowing treatment - LF furnace refining - RH vacuum degassing treatment - slab casting - slab into Pit slow cooling-walking heating furnace-high pressure water descaling-rolling mill rough rolling-rolling mill finish rolling-pre-leveling-MULPIC cooling-powerful straightening-spray number identification-stacking slow cooling-flaw detection-sampling inspection-warehousing -Ship.

[0036] The billet is heated to 1150°C to 1200°C, and then rolled. The rolling adopts double-stand controlled rolling, and the rough rolling mill performs rolling in the complete recrystallization zone above 980°C to reduce the waiting time for the intermediate billet and prevent excessive growth of recrystallized austenite. The deformation rate of the last two passes is 20% to 25%. . The f...

Embodiment 2

[0046] The overall process flow of 26.4mm X70MS wide and thick steel plate is: high-quality molten iron - KR molten iron pretreatment - 210 tons of top and bottom combined blowing converter - CAS station argon blowing treatment - LF furnace refining - RH vacuum degassing treatment - slab casting - step-by-step Heating furnace-high pressure water descaling-mill rough rolling-mill finish rolling-pre-leveling-MULPIC cooling-strong straightening-spray number marking-stacking slow cooling-flaw detection-sampling inspection-warehousing-delivery.

[0047] The billet is heated to 1150°C to 1200°C, and then rolled. The rolling adopts double-stand controlled rolling, and the rough rolling mill performs rolling in the complete recrystallization zone above 980°C to reduce the waiting time for the intermediate billet and prevent excessive growth of recrystallized austenite. The deformation rate of the last two passes is 20% to 25%. . The finish rolling mill is used for non-recrystallized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com