Method for preparing porous alginate gel microsphere adsorbing agent with electronic injection method

An alginate gel and microsphere adsorption technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of poor anion exchange resin effect and poor fluoride removal effect , difficult to remove dirt and other problems, to achieve good adsorption and separation effect, low cost, good economic benefits and the effect of popularization and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1. Add 2 parts by weight of sodium alginate to 96.3 parts by weight of distilled water to prepare an aqueous solution of sodium alginate, then add 1 part by weight of sodium dodecylbenzenesulfonate, 0.5 parts by weight of nano-calcium carbonate, and 0.2 parts by weight of bicarbonate sodium, stir evenly to obtain a blended sol;

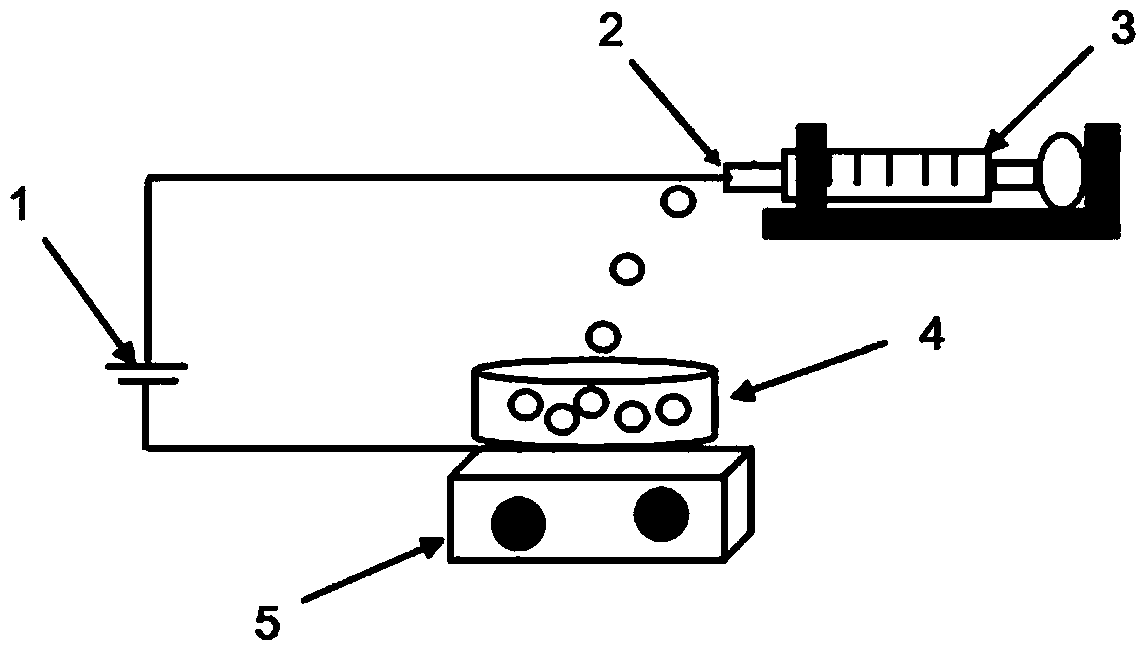

[0048] Step 2, put the blended sol into such as figure 1 In the electrospinning device shown, the electrospray blending sol was carried out under the condition that the ambient temperature of the electrospray was 30°C, the output voltage of the high-voltage power supply was 13kv, the distance between the receiving device and the spinneret was 14cm, and the flow rate was 1.0mL / h. In the receiving device, stir and filter to obtain porous calcium alginate microspheres, the receiving device contains a calcium chloride solution with a concentration of 2wt%, and the calcium chloride solution contains acetic acid, and the volume fraction of aceti...

Embodiment 2

[0051] Step 1. Add 1.5 parts by weight of sodium alginate to 96.4 parts by weight of distilled water to prepare an aqueous solution of sodium alginate, then add 0.2 parts by weight of sodium dodecylbenzenesulfonate, 1.5 parts by weight of nano-calcium carbonate, and 0.4 parts by weight of bicarbonate sodium, stir evenly to obtain a blended sol;

[0052] Step 2, put the blended sol into such as figure 1 In the electrospinning device shown, the electrospray blending sol was carried out under the condition that the ambient temperature of the electrospray was 30°C, the output voltage of the high-voltage power supply was 13kv, the distance between the receiving device and the spinneret was 14cm, and the flow rate was 1.0mL / h. In the receiving device, stir and filter to obtain porous calcium alginate microspheres, the receiving device contains a calcium chloride solution with a concentration of 2wt%, and the calcium chloride solution contains acetic acid, and the volume fraction of ...

Embodiment 3

[0055] Step 1. Add 1.5 parts by weight of sodium alginate to 95 parts by weight of distilled water to prepare an aqueous solution of sodium alginate, then add 0.2 parts by weight of sodium dodecylbenzenesulfonate, 2.5 parts by weight of nano-calcium carbonate, and 0.8 parts by weight of bicarbonate sodium, stir evenly to obtain a blended sol;

[0056] Step 2, put the blended sol into such as figure 1 In the electrospinning device shown, the electrospray blending sol was carried out under the environment temperature of 20°C, the output voltage of the high-voltage power supply was 12kv, the distance between the receiving device and the spinneret was 12cm, and the flow rate was 1.5mL / h. In the receiving device, stir and filter to obtain porous calcium alginate microspheres, the receiving device contains a calcium chloride solution with a concentration of 3wt%, and the calcium chloride solution contains acetic acid, and the volume fraction of acetic acid accounts for 8 %;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com