Fluorescent powder and preparation method thereof

A phosphor, infrared light technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of cumbersome, increased process, energy loss of mixture, etc., and achieve the effect of simple composition, simple synthesis process and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The flow chart of the synthesis method of the embodiment of the present invention is as follows Figure 5 shown. Using YF with a purity of 99.99% 3 , TmF 3 As the main raw material, the molecular composition is obtained as Tm x Y 1-x f 3 Sample (x takes a value of 0.05). Accurately weigh 0.9247g YF 3 and 0.0753g TmF 3 , mix well in a mortar and grind for 1 hour. Then add 5 mL of alcohol and grind for 1 hour. After drying at room temperature, the above mixture was placed in a corundum crucible and calcined in a high-temperature furnace with an HF atmosphere. The HF atmosphere was composed of NH 4 HF 2 Provided by decomposition; the calcination temperature is 700°C, and the calcination time is 6 hours. After the temperature of the sample was naturally lowered to room temperature with the high-temperature furnace, the sintered product was crushed to the required particle size to obtain the sample of the embodiment.

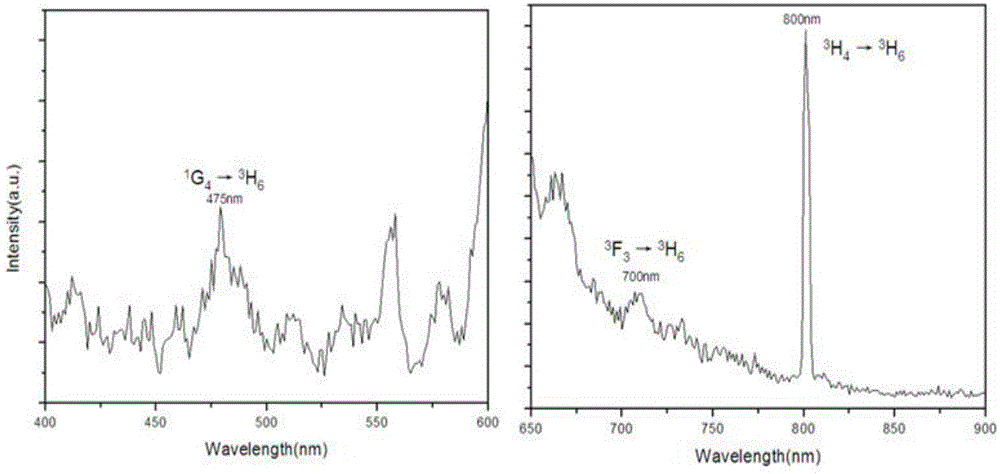

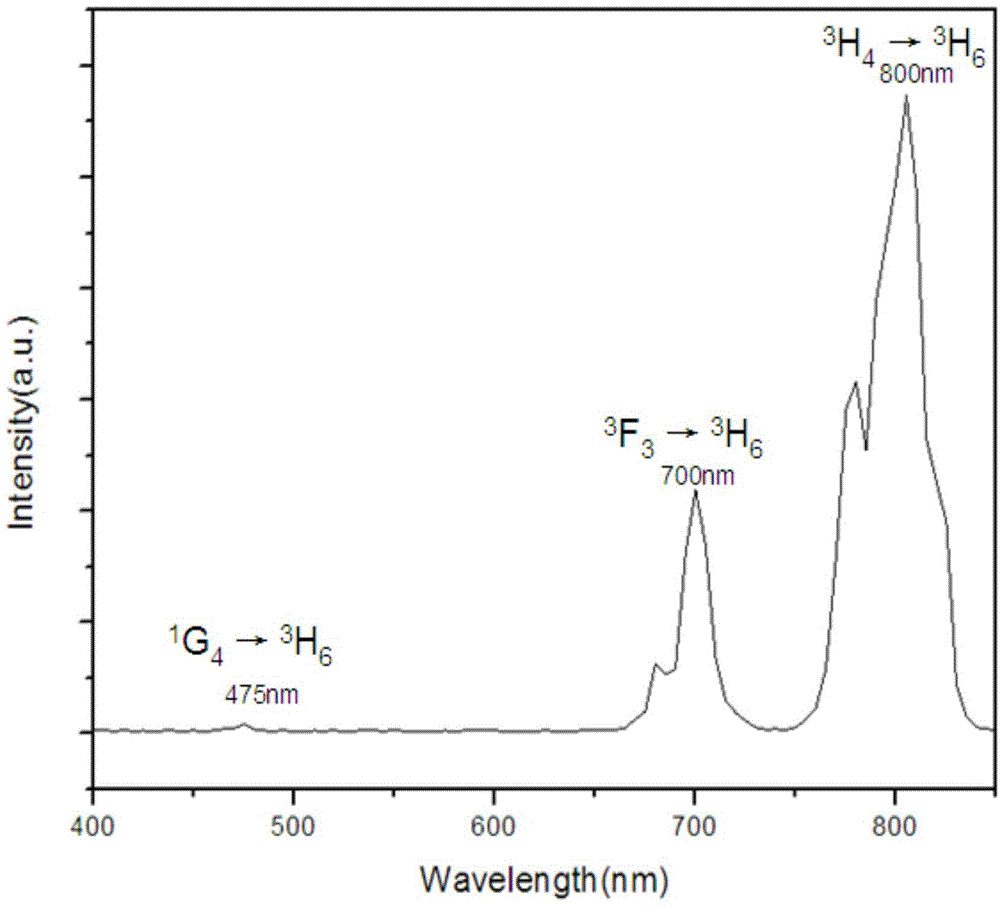

[0025] The embodiment of the present inventi...

Embodiment 2

[0027] The flow chart of the synthesis method of the embodiment of the present invention is as follows Figure 5 shown. Using YF with a purity of 99.99% 3 , TmF 3 As the main raw material, the molecular composition is obtained as Y 1-x T m x f 3 Sample (x takes a value of 0.1). Accurately weigh 0.8532g YF 3 and 0.1468g TmF 3 , mix well in a mortar and grind for 1 hour. Then add 5 mL of alcohol and grind for 1 hour. After drying at room temperature, the above mixture was placed in a corundum crucible, and placed in a high-temperature furnace for calcination, and the HF atmosphere was composed of NH 4 HF 2 Provided by decomposition; the calcination temperature is 700°C, and the calcination time is 6 hours. After the temperature of the sample was naturally lowered to room temperature with the high-temperature furnace, the sintered product was crushed to the required particle size to obtain the sample of the embodiment.

[0028] The embodiment of the present invention ...

Embodiment 3

[0030] The flow chart of the synthesis method of the embodiment of the present invention is as follows Figure 5 shown. Using YF with a purity of 99.99% 3 , TmF 3 As the main raw material, the molecular composition is obtained as Y 1-x T m x f 3 Sample (x takes a value of 0.0001). Accurately weigh 0.9998g YF 3 and 0.0002g TmF 3 , mix well in a mortar and grind for 1 hour. Then add 5 mL of alcohol and grind for 1 hour. After drying at room temperature, the above mixture was placed in a corundum crucible, and placed in a high-temperature furnace for calcination, and the HF atmosphere was composed of NH 4 HF 2 Provided by decomposition; the calcination temperature is 700°C, and the calcination time is 6 hours. After the temperature of the sample was naturally lowered to room temperature with the high-temperature furnace, the sintered product was crushed to the required particle size to obtain the sample of the embodiment.

[0031] The embodiment of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com