Halogen-free non-phosphorus silicon-containing flame retardant and preparation method thereof

A silicon flame retardant and catalyst technology, applied in the field of flame retardant and its preparation, can solve the problem of narrow processing window of modified bismaleimide resin, poor storage stability of hyperbranched polysiloxane, amino and imide The problem of fast reactivity of amine ring, etc., to achieve the effect of being conducive to large-scale application, good storage stability, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] in N 2 Under protection, 5.19g of maleic anhydride was dissolved in 100mL of toluene to form solution A; 11.7g of γ-aminopropyltriethoxysilane was added dropwise to the toluene solution within 30 minutes, and reacted at room temperature for 0.5 hours to form Solution B.

[0037] Add 7.2g of anhydrous zinc chloride to solution B, and after the temperature reaches 80°C, add 8.52g of hexamethyldisilazane dropwise within 30 minutes. After the dropwise addition, react at 80°C for 4h, filter, and distill under reduced pressure to obtain solution C.

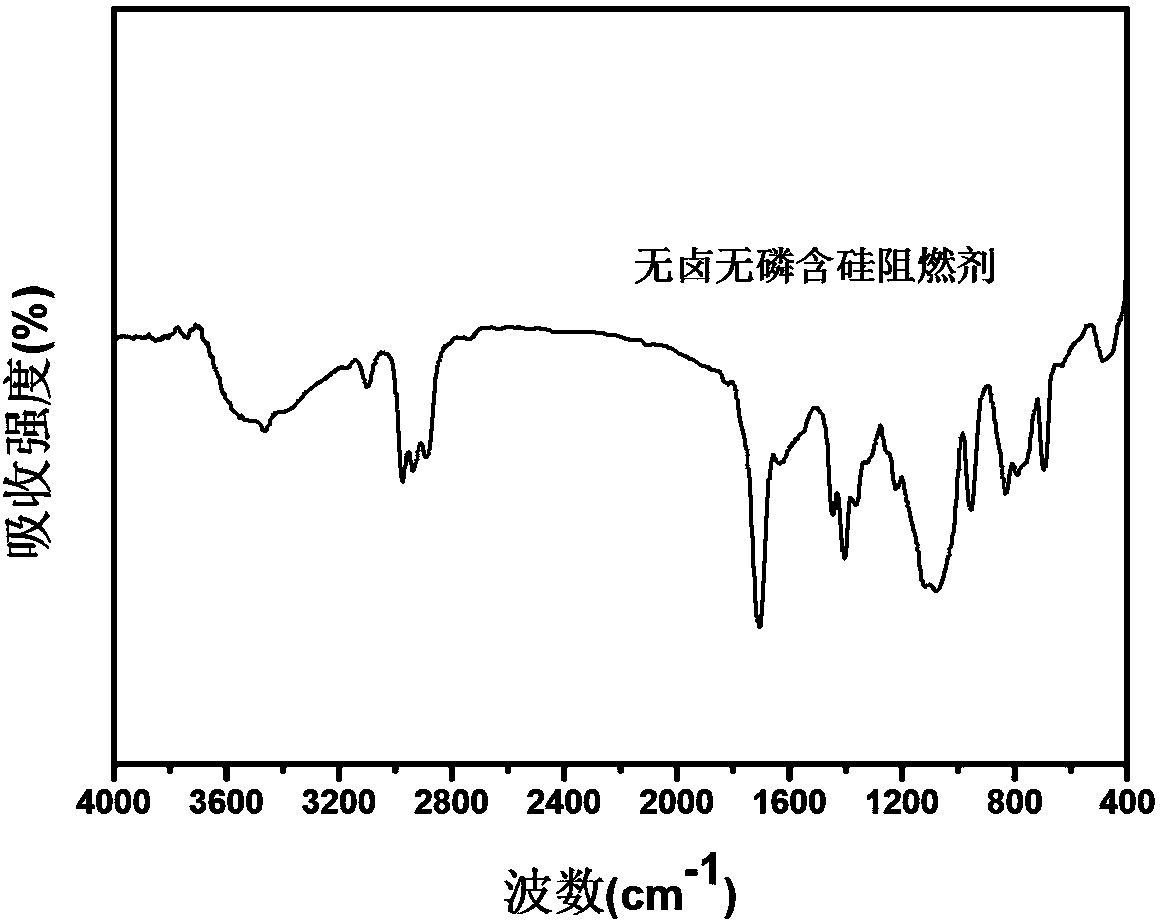

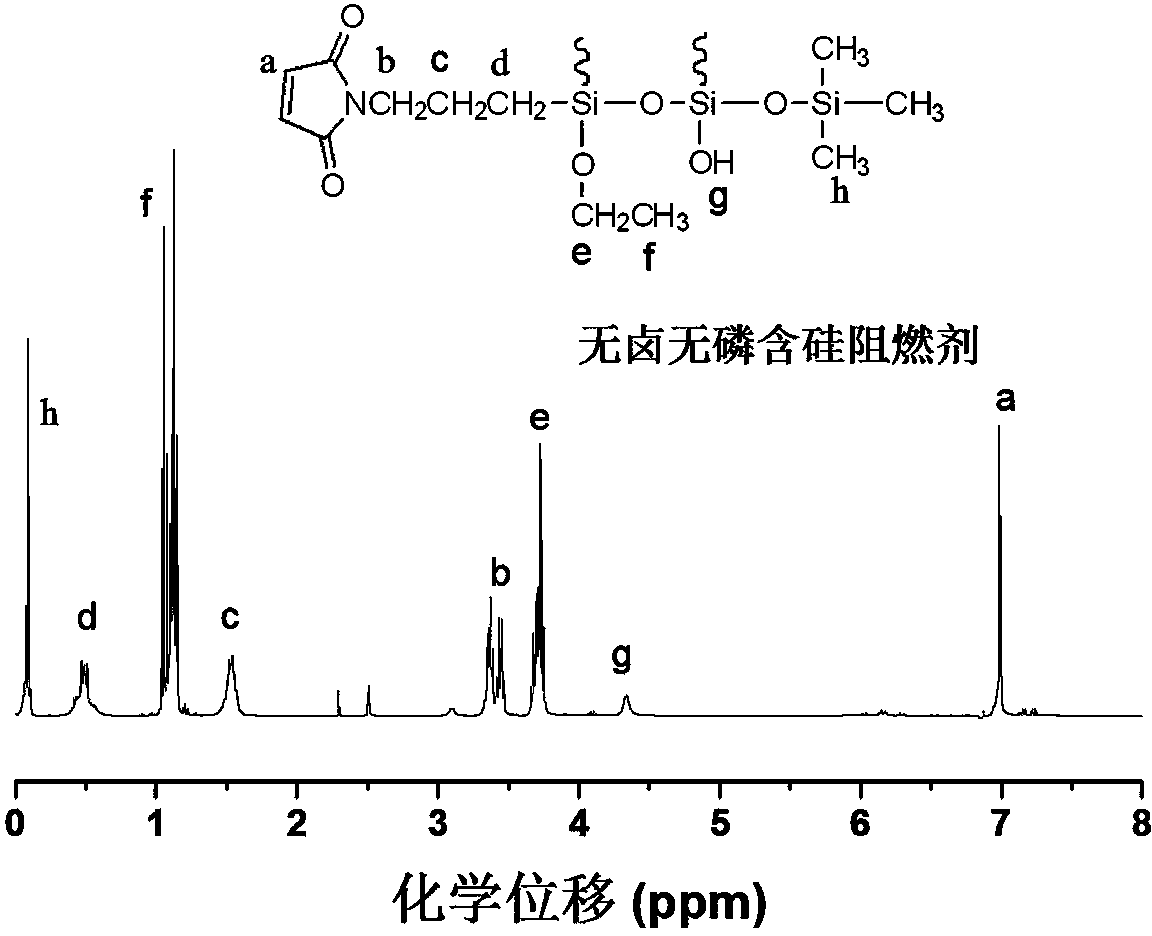

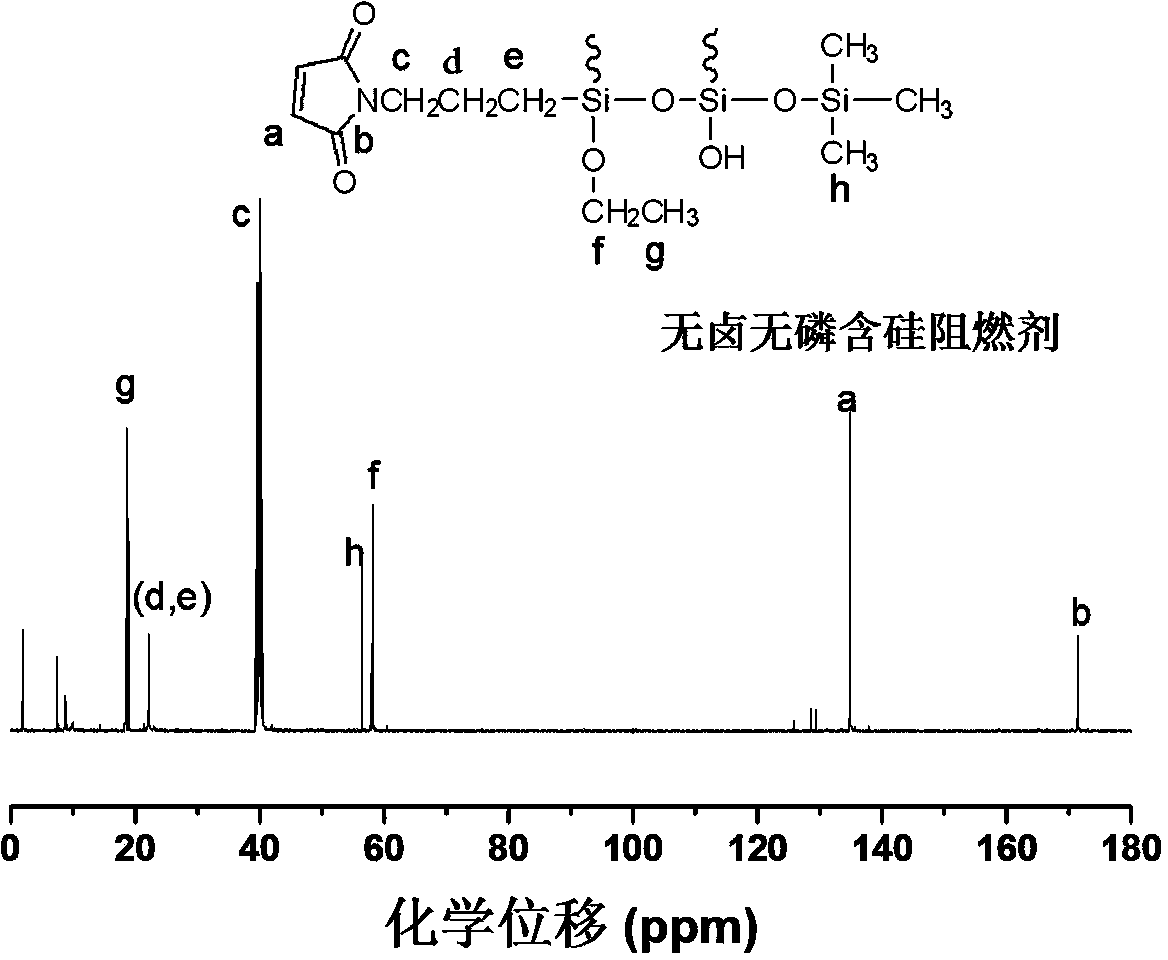

[0038] Add solution C, 1.14g deionized water and 0.01g tetramethylammonium hydroxide to ethanol, and reflux at 55°C for 3h. After the reaction was completed, the halogen-free, phosphorus-free and silicon-containing flame retardant was obtained by distillation under reduced pressure and vacuum drying. The number average molecular weight was 3080, the degree of branching was 0.52, and the yield was 70%. Its infrared spectrogram,...

Embodiment 2

[0054] in N 2 Under protection, 5.88g of maleic anhydride was dissolved in 100mL of toluene to form solution A; 13.3g of γ-aminopropyltriethoxysilane was added dropwise to the toluene solution within 20min, and then reacted at room temperature for 1h to form a solution b.

[0055] Add 8.2g of anhydrous zinc chloride to solution B, and after the temperature reaches 70°C, add 9.2g of hexamethyldisilazane dropwise within 30min. After the dropwise addition, react at 80°C for 4h, filter, and distill under reduced pressure to obtain solution C.

[0056] Add solution C and 1.4g deionized water into ethanol (adjust pH=10 with NaOH), and reflux at constant temperature at 55°C for 4h. After the reaction was completed, the halogen-free, phosphorus-free and silicon-containing flame retardant was obtained by distillation under reduced pressure and vacuum drying. The number average molecular weight was 3225, the degree of branching was 0.55, and the yield was 68%.

Embodiment 3

[0058] in N 2 Under protection, 15.8g of maleic anhydride was dissolved in 250mL of toluene to form solution A; a mixture of 15.1g of γ-aminopropyltriethoxysilane and 20g of γ-aminopropyltrimethoxysilane was added dropwise within 30min Toluene solution, and then react at room temperature for 0.5h to form solution B.

[0059] Add 21.6g of anhydrous zinc chloride to solution B, and after the temperature reaches 70°C, add 25.56g of hexamethyldisilazane dropwise within 25 minutes. After the dropwise addition, react at 70°C for 5h, filter, and distill under reduced pressure to obtain solution C.

[0060] Add solution C, 3.4g deionized water and 0.05g tetramethylammonium hydroxide into methanol, and reflux at 55°C for 4h. After the reaction was completed, the halogen-free, phosphorus-free and silicon-containing flame retardant was obtained by distillation under reduced pressure and vacuum drying. The number average molecular weight was 2988, the degree of branching was 0.52, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com