Preparation method of catalyst for preparing propylene by virtue of propane dehydrogenation

A propane dehydrogenation and catalyst technology, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, hydrocarbons, etc., can solve the problems of pollution and high product cost, reduce energy consumption, reduce preparation costs, and reduce calcination temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

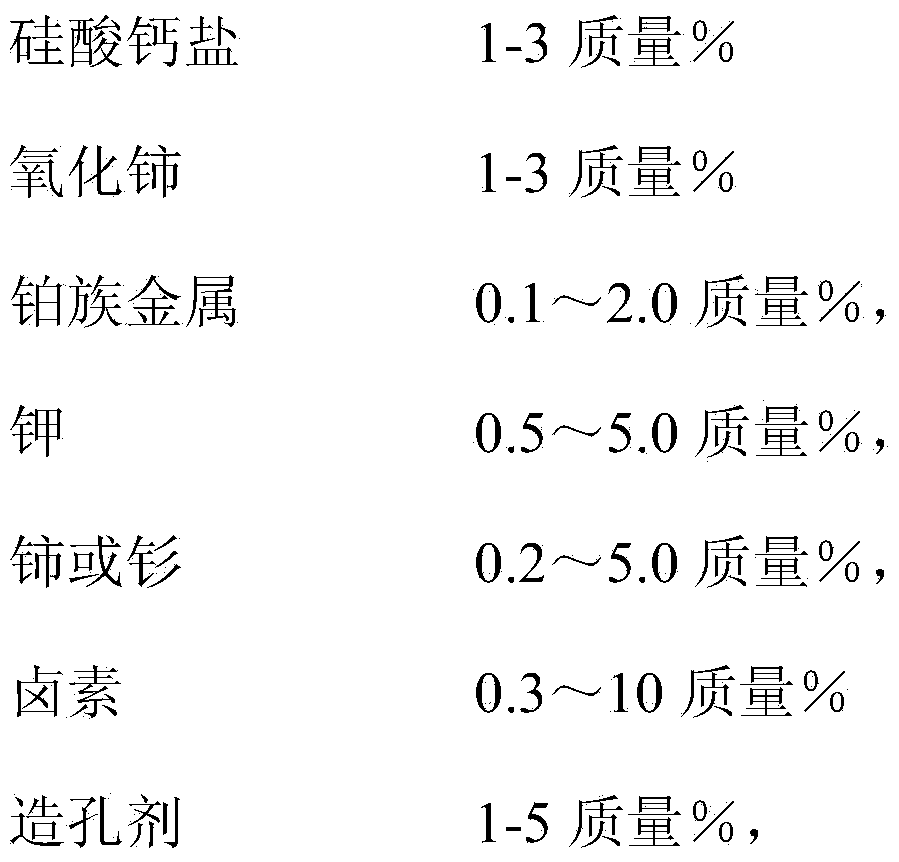

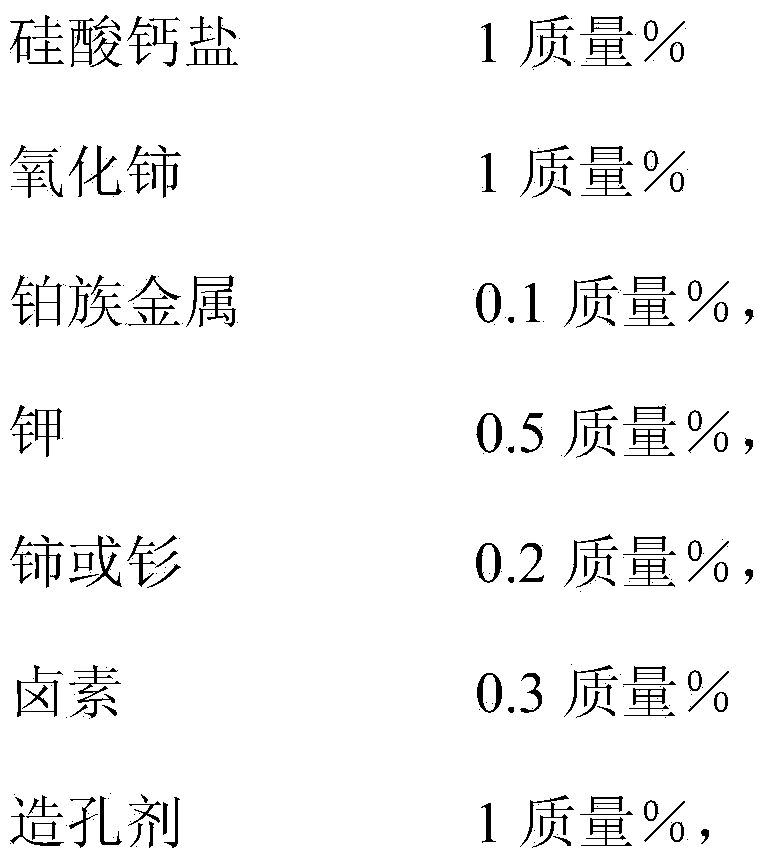

[0021] A method for preparing a catalyst for the dehydrogenation of propane to propylene, comprising an alumina carrier and active components with the following contents based on the carrier as a calculation basis:

[0022]

[0023] The balance is impurities;

[0024] The molar ratio of cerium or samarium to platinum group metal is 7:8; the platinum group metal is platinum; the halogen is chlorine;

[0025] The alumina carrier is impregnated with a soluble cerium or samarium compound solution, a calcium silicate salt solution, dried and calcined, and then impregnated with a platinum group metal compound and a hydrogen halide solution, dried, calcined, and then impregnated with a potassium salt solution. Drying and calcining; then mixing the above-mentioned corresponding amounts of cerium oxide and pore-forming agent, and calcining at 600° C. for 3 hours to obtain the catalyst for the dehydrogenation of propane to propylene.

Embodiment 2

[0027] A method for preparing a catalyst for the dehydrogenation of propane to propylene, comprising an alumina carrier and active components with the following contents based on the carrier as a calculation basis:

[0028]

[0029] The balance is impurities;

[0030] The molar ratio of cerium or samarium to platinum group metal is 7:8; the platinum group metal is platinum; the halogen is chlorine;

[0031] The alumina carrier is impregnated with a soluble cerium or samarium compound solution, a calcium silicate salt solution, dried and calcined, and then impregnated with a platinum group metal compound and a hydrogen halide solution, dried, calcined, and then impregnated with a potassium salt solution. Drying and calcining; then mixing the above-mentioned corresponding amounts of cerium oxide and pore-forming agent, and calcining at 600° C. for 3 hours to obtain the catalyst for the dehydrogenation of propane to propylene.

Embodiment 3

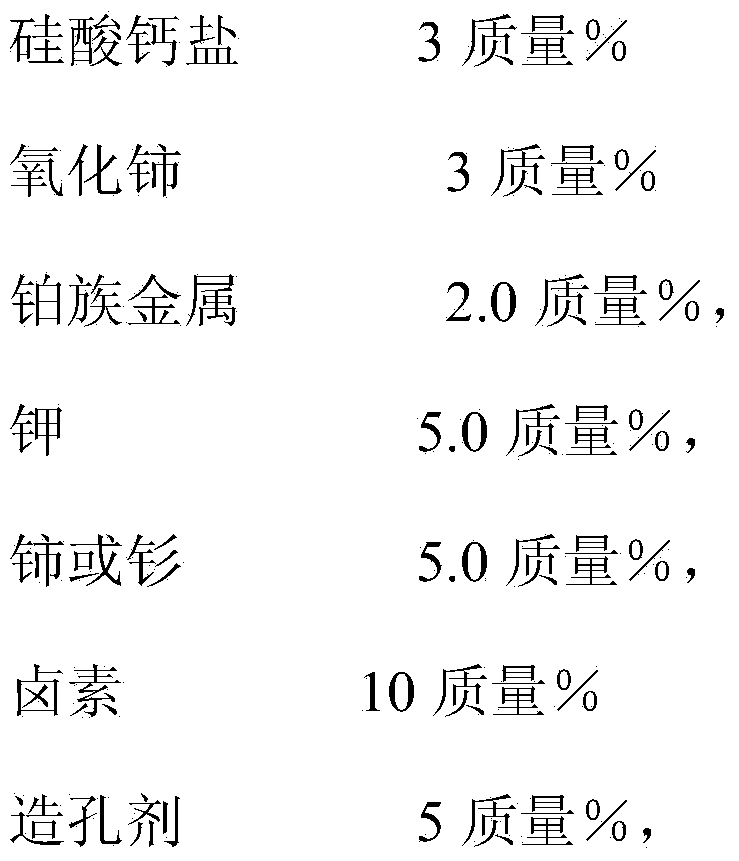

[0033] A method for preparing a catalyst for the dehydrogenation of propane to propylene, comprising an alumina carrier and active components with the following contents based on the carrier as a calculation basis:

[0034]

[0035] The balance is impurities;

[0036] The molar ratio of cerium or samarium to platinum group metal is 7:8; the platinum group metal is platinum; the halogen is chlorine;

[0037] The alumina carrier is impregnated with a soluble cerium or samarium compound solution, a calcium silicate salt solution, dried and calcined, and then impregnated with a platinum group metal compound and a hydrogen halide solution, dried, calcined, and then impregnated with a potassium salt solution. Drying and calcining; then mixing the above-mentioned corresponding amounts of cerium oxide and pore-forming agent, and calcining at 600° C. for 3 hours to obtain the catalyst for the dehydrogenation of propane to propylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com