Lithium-ion battery pole piece with inorganic separation layer, battery including the pole piece, and method for preparing the pole piece

A technology of lithium-ion batteries and battery pole pieces, which is applied in the field of lithium-ion batteries, can solve the problems of poor flexibility of inorganic diaphragms, achieve the effects of reducing electrochemical polarization, simple process, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

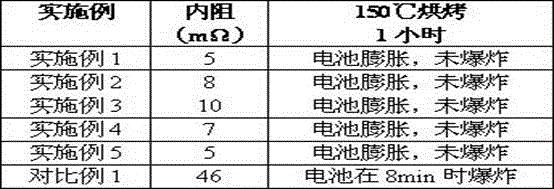

Examples

preparation example Construction

[0032] The preparation method of the lithium ion battery pole piece with inorganic barrier layer of the present invention, comprises the steps:

[0033] A. Provide disc-shaped lithium-ion battery pole pieces that are cut into continuous monomers; preferably, laser cutting is used to ensure that the edges of the pole pieces are free of burrs, and eliminate self-discharge and safety hazards.

[0034] B. Mix the inorganic powder, stabilizer, and binder, and add a dispersant to make a uniform mixed dispersion system, and then apply the mixed dispersion system to the battery pole piece to form a film layer; preferably, the inorganic powder is α - One or more of aluminum oxide, silicon dioxide, magnesium oxide, and zirconia; the binder is an acrylate adhesive; the stabilizer is polyvinylidene fluoride (PVDF), polytetrafluoroethylene (PTFE), polyethylene, methylcellulose, hydroxypropylmethylcellulose, sodium carboxymethylcellulose (CMC), hydroxyethylcellulose, silica gel, polyacrylam...

Embodiment 1

[0042] A. The positive electrode sheet with active material on both sides (5.8mAh / cm 2 ) Roller, laser slitting into a disc shape of continuous monomer;

[0043] B. Mix 35wt% of α-aluminum oxide (average particle size of α-aluminum oxide is 400~600nm), 61wt% of pure water, 3wt% of CMC, and 1wt% of ethyl methacrylate Form a uniform mixed dispersion system; then apply the mixture dispersion system on the cut positive electrode sheet to form a film layer with a thickness of about 60 μm;

[0044] C. Dry the pole piece with the film layer through a high-temperature tunnel furnace. The treatment temperature is 120°C and the treatment time is 6 minutes. pole piece.

[0045] The porosity of the electrode sheet was determined to be 60% by a gravimetric method, and the pore diameter measured by a pore size tester was 60 nm.

[0046] Glue the edge of the positive electrode sheet of the lithium-ion battery with the inorganic separation layer prepared above, cut small pieces, and be equ...

Embodiment 2

[0048] A. The negative electrode sheet (6.3mAh / cm2) with active material on both sides 2 ) Roller, laser slitting into a disc shape of continuous monomer;

[0049] B. Mix 35 wt% of α-aluminum oxide (the average particle size of α-aluminum oxide is 600~800nm), 61 wt% of pure water, 3 wt% of CMC, and 1 wt% of ethyl methacrylate Make a uniform mixed dispersion system; then apply the mixed dispersion system on the cut negative electrode sheet to form a film layer with a thickness of about 60 μm;

[0050] C. Dry the pole piece with the film layer through a high-temperature tunnel furnace. The treatment temperature is 120°C and the treatment time is 6 minutes. pole piece.

[0051] The porosity of the electrode sheet was determined to be 75% by a gravimetric method, and the pore diameter measured by a pore size tester was 100 nm.

[0052] Glue the edge of the negative electrode sheet of the lithium-ion battery with an inorganic separator prepared above, cut into small pieces, matc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com