Carrier for microarray biochip, preparation method of carrier and microarray biochip

A biochip and microarray technology, applied in the field of microarray biochips and carriers of microarray biochips, can solve the problem of lack of universal functional groups for immobilized biomolecules, difficult liquid injection and flow control in microfluidic pipelines, and high obstacles. The wide application of molecular materials to achieve the effect of avoiding individual differences, good reactivity, and convenient functional modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

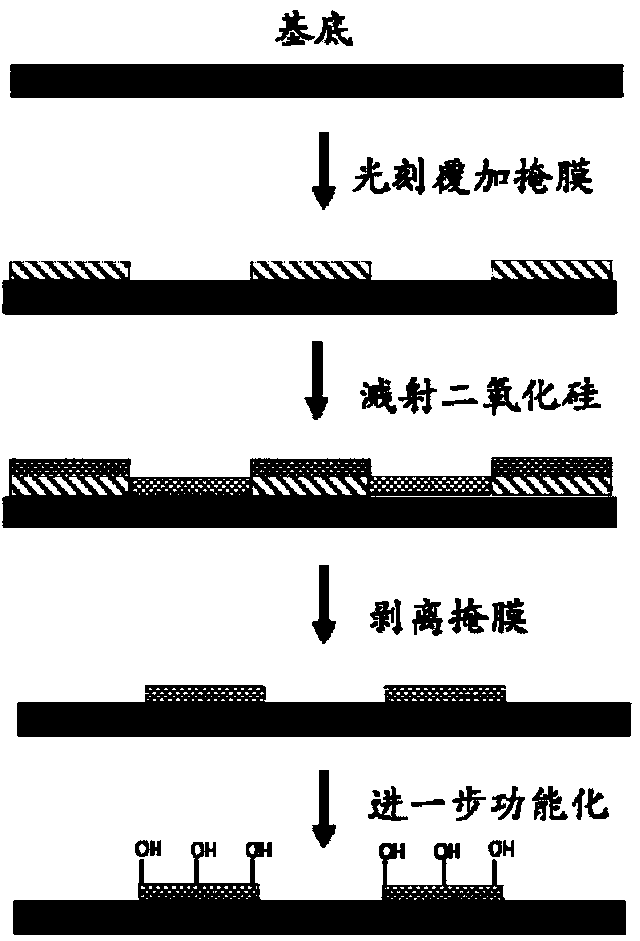

[0041] The present invention provides a method for preparing a carrier for a microarray biochip described in the above technical scheme, comprising the following steps:

[0042] Applying a photolithography method to coat a plurality of masks on the surface of the polymer substrate, and the plurality of masks are distributed in an array on the surface of the polymer substrate;

[0043] physical vapor deposition of a silicon dioxide film on the polymer substrate covered with a mask to obtain a carrier precursor;

[0044] The mask on the carrier precursor is peeled off to obtain a carrier for microarray biochips.

[0045] In the present invention, preferably, the polymer material is first molded, injected and cut to obtain a polymer material of suitable size and shape. In the present invention, the material, size, and shape of the polymer substrate are consistent with those of the polymer substrate in the above technical solution, and will not be repeated here.

[0046] After o...

Embodiment 1

[0077] (1) Cyclic olefin copolymer (purchased from Topas, USA) is processed into a rectangular substrate of 76 mm × 26 mm by a plastic thermocompression molding machine;

[0078] (2) Use NH with a volume ratio of 1:1:5 4 OH:H 2 o 2 :H 2 O mixed solution Wash the cycloolefin copolymer substrate obtained in step (1) at 80° C. for 15 minutes. Dry the substrate under vacuum at 110°C for 1 hour with nitrogen flow;

[0079] (3) Rotate at a speed of 4000 rpm for 30 s, spin-coat a thin layer of positive photoresist Shipley 1813 (purchased from MicroChem, USA) onto the substrate obtained in step (2), and dry at 80° C. for 2 min. A Karl-Suss lithography machine (purchased from Karl Suss, Germany) was used for photolithography, and developed by MF 319 developer (purchased from MicroChem, USA);

[0080] (4) Deposit a silicon dioxide film on the substrate obtained in step (3) using a Kurt Lesker PVD 75 radio frequency magnetron sputtering system (purchased from Kurt J.Lesker, USA): th...

Embodiment 2

[0085] (1) Polycarbonate (purchased from Sinopharm Chemicals) was processed into a rectangular substrate of 76mm×26mm by a plastic thermoforming machine;

[0086] (2) The substrate obtained in step (1) was ultrasonically cleaned with ethanol and deionized water for 5 minutes and 10 minutes in sequence, and the substrate was dried under nitrogen flow and then vacuum-dried at 80° C. for 0.5 hours;

[0087] (3) Rotate at a speed of 4000 rpm for 30 s, spin-coat a thin layer of positive photoresist Shipley 1813 (purchased from MicroChem, USA) onto the substrate obtained in step (2), and dry at 80° C. for 2 min. A Karl-Suss lithography machine (purchased from Karl Suss, Germany) was used for photolithography, and developed by MF 319 developer (purchased from MicroChem, USA);

[0088] (4) Use a vacuum ion sputtering coating machine (Sputter Coating SCD005, purchased from Finland BAL-TEC company) to sputter deposit a silicon dioxide film on the substrate obtained in step (3): the work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com