Horizontal screw structure pyrolysis furnace for recycling waste tire resources

A horizontal screw and rod structure technology, applied in plastic recycling, recycling technology, preparation of liquid hydrocarbon mixture, etc., can solve problems affecting operation safety, leakage of pyrolysis gas, poor sealing performance, etc., to prolong residence time, The effect of short production cycle and large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

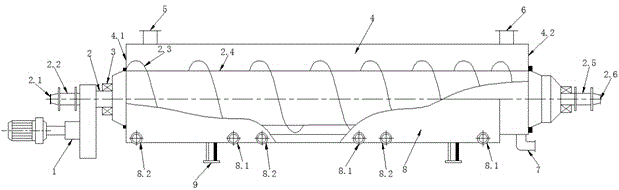

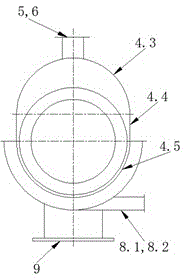

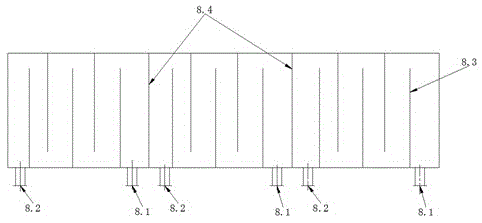

[0019] Such as figure 1 , figure 2 As shown, the present invention has a closed body of furnace 4, the left side of the upper part of the body of furnace 4 and the right side of the upper part are respectively provided with a tire block inlet pipe 5 and a cracking gas outlet pipe 6, and a rotor 2 is arranged in the body of furnace 4, and the rotor 2 The two ends are respectively supported in the left and right bearing supports 3, and the rotor 2 is driven to rotate through the transmission system 1 at the left end. A heating jacket 8 is arranged on the outer lower part of the furnace body 4, and a pyrolysis product outlet pipe 7 is arranged on the lower right end of the furnace body 4. , the whole device is installed on the saddle support 9.

[0020] Such as figure 1 , figure 2 As shown, the furnace body 4 is jointly surrounded by a left end plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com