Biological bactericide for preventing and controlling SRB (sulfate reducing bacteria) in high-temperature water body and SRB inhibition method of bactericide

A biological agent and high-temperature technology, applied in the direction of chemicals for biological control, botany equipment and methods, biocides, etc., can solve the problems of drug resistance, easy secondary pollution, less research, etc., to achieve Effects of eliminating sulfides, reducing production costs, and changing community structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

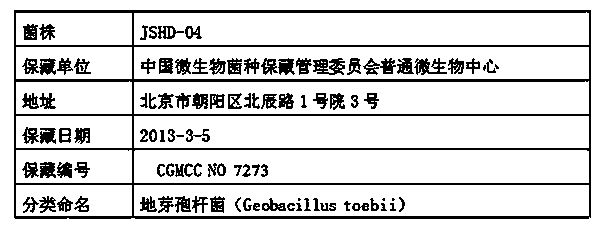

[0016] JSHD-4 Geobacillus of the present invention is screened by the following process:

[0017] (1) Sample collection

[0018] The production fluids of 7 oil wells were collected in Jiangsu Oilfield. The sample names are: CH2-43, CH2-42, CH2-36, T83-1, T83-10, T83-7, H88-10.

[0019] (2) Culture medium configuration

[0020] The enrichment medium is composed of A solution and B solution, in which:

[0021] Solution A: 2.0 g inorganic salt K1, 1.0 g asparagine, 500 ml distilled water, pH 7.0~7.2;

[0022] Solution B: 8.5 g sodium citrate, 2 g sodium acetate, 2 g glucose, KH 2 PO 4 0.5 g, K 2 HPO 4 0.5 g, MgSO 4 ·7H 2 O 1.0 g, FeCl 3 ·6H 2 O 0.05 g, CaCl 2 0.1 g, yeast extract 0.5 g, distilled water 500 ml. The pH value is 7.0~7.2.

[0023] NRB liquid medium: liquid A and liquid B are sterilized separately at 121 ℃ for 20 min, and mixed in equal proportions after sterilization.

[0024] NRB solid medium: add agar with a mass ratio of 1.5% to 2% to liquid A and...

Embodiment 2

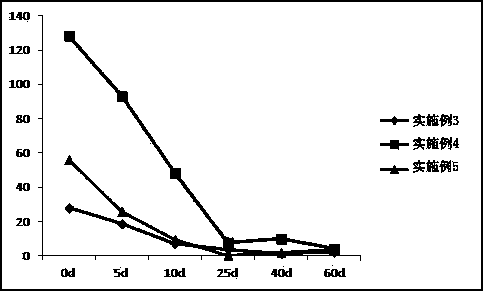

[0065] Inhibitory effect of JSHD-4 on SRB under laboratory system conditions

[0066] According to the formula of improved SRB medium in Table 3, the medium was prepared with sterile water as the solvent, the medium was sterilized at 121 °C for 20 min, and after cooling, trace element solutions were added to each liter of medium (the composition is shown in Table 4) 1 mL, 1 mL of vitamin solution (the composition is shown in Table 5), 0.1 g of ferrous ammonium sulfate sterilized by ultraviolet light and 0.5 g of L-cysteine hydrochloride; The SRB strains (Desulfurizing Enterobacteriaceae) were inoculated into SRB medium in 3~4 loops, and cultured at 65°C for 48 hours to obtain freshly enriched cultured SRB strains.

[0067] At the same time, the preserved JSHD-4 was activated and cultured at 75 °C using NRB liquid medium (the same as the NRB liquid medium in Example 1) for 1 day to obtain a freshly enriched cultured JSHD-4 bacterial liquid, and then inoculated at 2% Ratio In...

Embodiment 3

[0073] First, the denitrifying bacteria JSHD-4 was prepared by conventional microbial aerobic fermentation to obtain a spore concentration of 1.0×10 6 cfu / mL industrial fermentation liquid, the industrial fermentation liquid can be stored in 20L plastic barrels, and then sodium nitrate, sodium nitrite and sodium dihydrogen phosphate are all commercially available industrial grade products, and they are mixed evenly in proportion when used, or they can be added in sequence Target oil well production fluid.

[0074] The JSHD-4 multifunctional biological bacterial agent of the present invention is put into Wang 39 well of Jiangsu Oilfield according to the following ratio, and the sulfide concentration of the output fluid of this well before treatment is 28mg / L. The dosage is: JSHD-4 industrial fermentation broth (1.0×10 6 cfu / mL), the dosage is 0.5% of the production fluid content; sodium nitrate: 20mg / L; sodium nitrite: 50mg / L; sodium dihydrogen phosphate: 5mg / L

[0075] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com